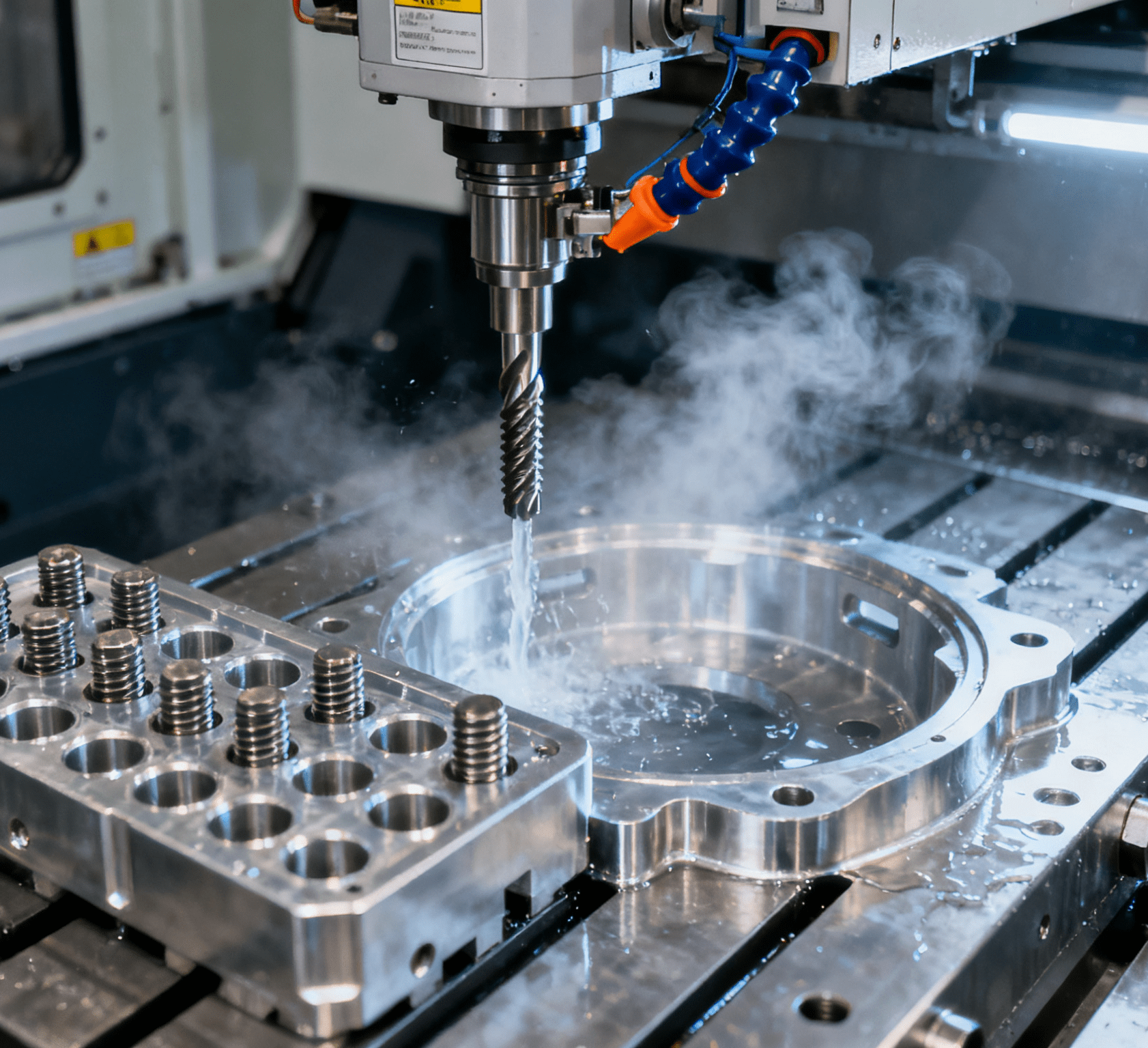

In the field of precision machining, the wear condition of cutting tools exerts a crucial impact on machining accuracy and product quality. Especially in high-demand machining scenarios such as CNC precision machining, precision mechanical machining, and medical component machining, even micro-wear of cutting tools may lead to dimensional deviations of parts, increased surface roughness, and even the failure of the entire machining process. Therefore, accurately monitoring the micro-wear of cutting tools has become a key link to ensure the smooth progress of precision machining.

This demand for micro-wear monitoring is equally prominent in the operation of automatic placement machines, core equipment in precision electronic manufacturing. The placement heads of automatic placement machines are equipped with precision tools such as suction nozzles and positioning pins. These tools directly contact and handle tiny electronic components (some even at the chip level) during the placement process. Once micro-wear occurs—such as the wear of the suction nozzle’s inner wall reducing adsorption stability, or the blunting of the positioning pin affecting positioning accuracy—it will cause deviations in component placement, resulting in defects like false soldering and offset, and seriously affecting the yield of electronic products. Thus, the micro-wear monitoring of such special tools in automatic placement machines also relies on targeted technical methods.

Optical Monitoring Method

Optical monitoring is a relatively intuitive approach. During the machining of precision parts, the cutting edge of the tool is observed regularly using an optical microscope or an electron microscope. For instance, in the CNC machining industry in Dongguan, some enterprises utilize high-resolution optical microscopes to magnify the cutting edge of the tool by tens or even hundreds of times for observation. By comparing the morphology of the new tool edge with that after a certain period of use, wear marks on the tool can be clearly identified, such as the increased fillet of the cutting edge and the appearance of tiny notches on the edge.

Advantages: It allows direct observation of the wear location and wear degree of the tool.

Disadvantages: It requires machine shutdown for observation, making real-time online monitoring impossible, and quantitative analysis of the wear amount is relatively difficult.

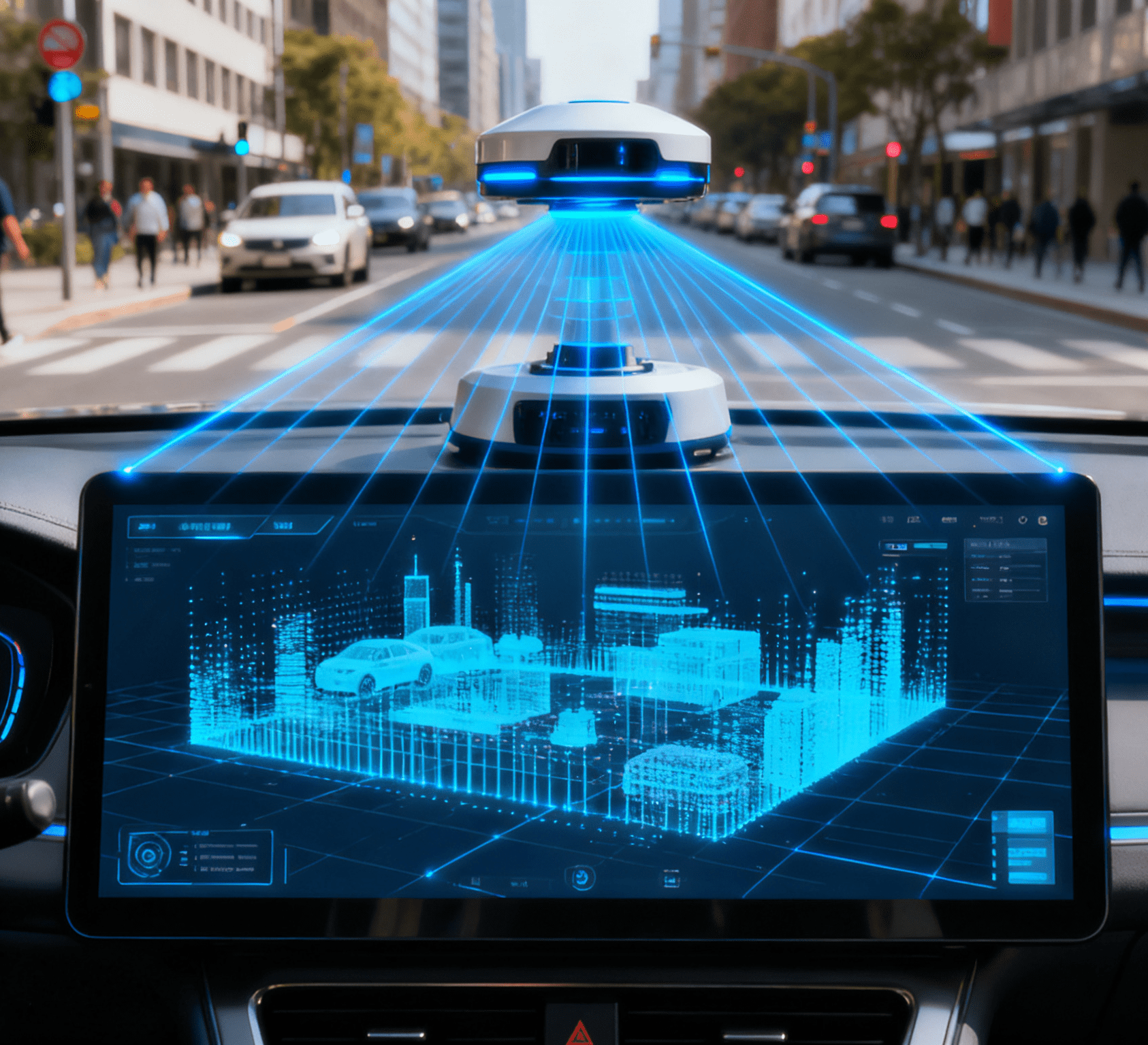

Vibration Monitoring Method

During the cutting process, tool wear causes changes in cutting force, which in turn leads to alterations in the vibration state of the machine tool. In CNC machining, vibration sensors can be installed on parts such as the machine tool spindle and tool holder to collect vibration signals in real time. When micro-wear occurs on the tool, the frequency and amplitude of the vibration signals undergo characteristic changes. Professional signal processing software can analyze these vibration signals, and by establishing a mathematical model between vibration characteristics and tool wear amount, the monitoring of tool micro-wear is achieved.

For example, when machining complex curved surface parts using 4-axis CNC machining, the vibration monitoring system can promptly capture abnormal vibrations caused by tool wear, issue early warnings about the tool’s wear state, and avoid part scrapping due to excessive tool wear.

Advantages: It enables real-time online monitoring without affecting the continuity of the machining process.

Disadvantages: It has high requirements for the analysis and processing of vibration signals, and requires professional technicians for operation and maintenance.

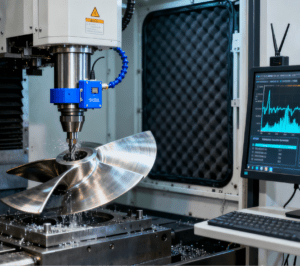

Cutting Force Monitoring Method

Cutting force is the result of the interaction between the tool and the workpiece, and tool wear directly causes changes in cutting force. In precision machining, force sensors are installed on the machine tool’s worktable or tool system to measure the cutting force during the cutting process. Generally, as the tool undergoes micro-wear, the cutting force gradually increases.

Taking mold machining as an example, when milling the mold cavity, the cutting force monitoring system can monitor changes in cutting force in real time. When the cutting force exceeds the normal range, it indicates that the tool may have a certain degree of wear. Through the analysis of cutting force data, not only can the wear state of the tool be determined, but also the remaining service life of the tool can be predicted based on the changing trend of the cutting force.

Advantages: It has high measurement accuracy and strong reliability.

Disadvantages: The installation position and measurement accuracy of the force sensor are affected by the machine tool structure and machining process, requiring reasonable design and debugging.

Acoustic Emission Monitoring Method

During the tool cutting process, acoustic emission occurs due to the deformation and fracture of materials. Acoustic emission signals contain abundant information about tool wear. In 5-axis CNC machining, acoustic emission sensors are used to collect acoustic emission signals during the cutting process. When micro-wear occurs on the tool, the intensity and frequency characteristics of the acoustic emission signals change.

By performing processing such as filtering, amplification, and feature extraction on the acoustic emission signals, and establishing a tool wear prediction model combined with machine learning algorithms, accurate monitoring of tool micro-wear can be achieved.

Advantages: It is highly sensitive to the monitoring of early micro-wear of tools and has a fast response speed.

Disadvantages: Acoustic emission signals are easily interfered by noise in the machining environment, requiring effective noise reduction measures.

There are various methods for monitoring the micro-wear of cutting tools in precision machining, and each method has its unique advantages and limitations. In practical applications, it is necessary to comprehensively select an appropriate monitoring method based on factors such as the specific machining process, machine tool equipment, and cost budget. This ensures that the wear condition of the tool is monitored in a timely and accurate manner, providing strong support for the smooth progress of precision machining.