As a professional provider of non-standard automation solutions, Ruizhi Intelligent Manufacturing focuses on empowering the cosmetic industry’s mass production needs. Our Industrial Automatic Lipstick Assembly Machine is engineered for high-volume, stable, and precise lipstick assembly, breaking through the limitations of traditional equipment and becoming a core asset for cosmetic factories pursuing scale production and cost optimization.

High-Volume Production Capacity to Meet Industrial Demands

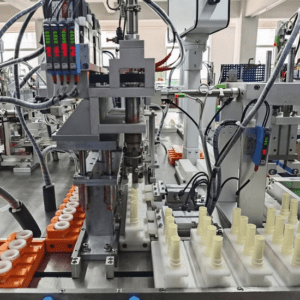

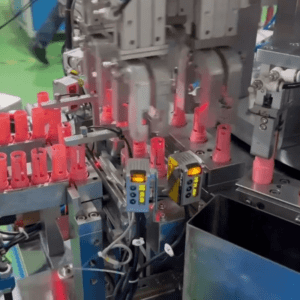

Tailored for cosmetic mass production, this industrial-grade machine integrates full-process automation from automatic feeding, lipstick core assembly, tube fitting, to capping and finished product sorting. Adopting a high-speed transmission system and optimized workflow design, it achieves a production capacity of 80-120 pieces per minute, supporting 24-hour continuous operation with low failure rates. Compared with manual assembly, it boosts production efficiency by over 300%, effectively addressing the pain points of labor shortage and low throughput in large-scale cosmetic factories, and laying a solid foundation for meeting peak season order demands.

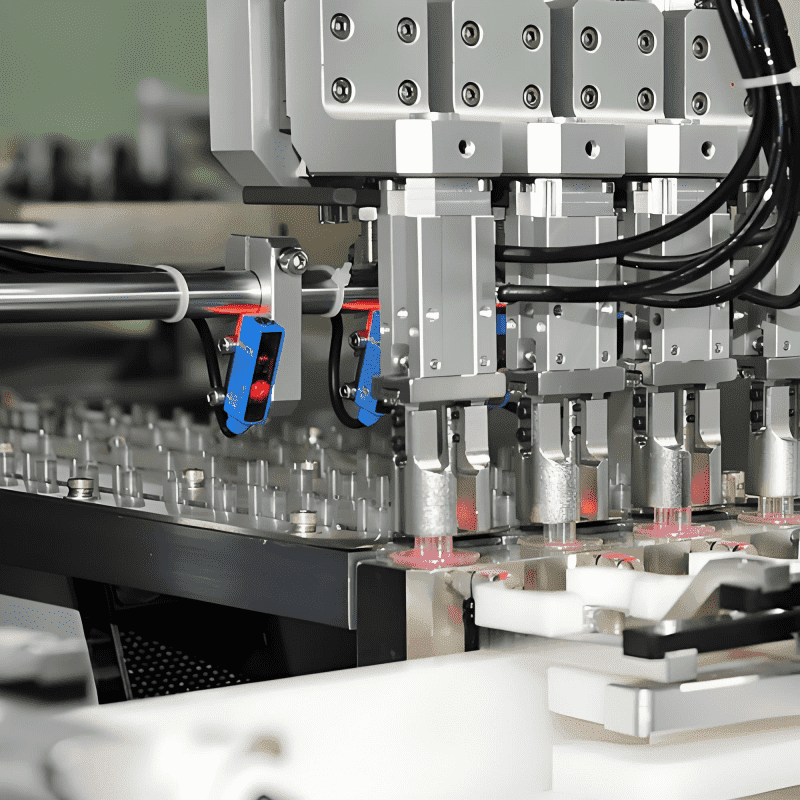

Industrial-Grade Precision & Stability Ensure Consistent Quality

Ruizhi’s Industrial Automatic Lipstick Assembly Machine adopts PLC intelligent control and high-precision servo drive technology, realizing an assembly accuracy of ±0.02mm. The built-in AI visual inspection module conducts real-time detection on lipstick core alignment, tube fitting tightness, and surface defects, reducing the defect rate to below 0.3%. Made of 304 stainless steel core components, it complies with FDA and CE food-grade hygiene standards, avoiding cross-contamination and ensuring consistent quality in mass production—critical for cosmetic brands maintaining market reputation.

Customizable Adaptability for Diverse Mass Production Scenarios

As a non-standard automation expert, we understand the diverse specifications of mass-produced lipsticks (bullet-shaped, liquid, matte, etc.) and tube materials (aluminum, plastic). The machine features a modular design, supporting customized adjustment of tube diameter (8-15mm), assembly process, and sorting mode to fit different product lines. Ruizhi provides one-stop services from scheme design, equipment customization to on-site debugging and after-sales maintenance, ensuring the machine seamlessly integrates into existing mass production lines and maximizes production value for clients.

Ruizhi Intelligent Manufacturing’s Industrial Automatic Lipstick Assembly Machine combines efficiency, precision, and adaptability, helping cosmetic enterprises achieve cost reduction, quality improvement, and efficiency enhancement in mass production, and gain a competitive edge in the fierce market.