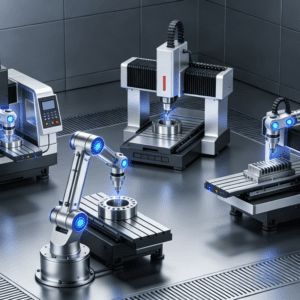

In modern manufacturing, precision machining technology is one of the core links to ensure product accuracy and quality. With the continuous advancement of technology, precision machining has been widely applied in fields such as aerospace, automotive, electronics, and medical care. By using different processing technologies, it is possible to meet the requirements of various products for precision, complex shapes, and efficient production.

This article will introduce several commonly used processes in precision machining, including their principles, applications, and advantages. By understanding these technologies, you will better comprehend how they enhance production efficiency and machining accuracy.

Milling: A Versatile Tool for High Efficiency and Precision

Milling is one of the most common processes in precision machining. It removes excess material by bringing a rotating cutting tool into contact with the workpiece surface, thereby achieving the desired shape and size. Milling is widely used in the manufacturing of complex shapes such as flat surfaces, grooves, and gears.

Advantages of Milling:

High Precision: Milling can achieve very high precision, typically enabling dimensional tolerances down to the micrometer level.

Flexibility: It is suitable for a wide range of materials, including metals, plastics, and composites.

Complex Shape Machining: It can process complex geometric shapes such as curved surfaces, spirals, and inclined planes.

Common Applications:

Machining of mechanical components

Housings and fine parts of electronic products

Machining of precision molds

Cutting: Precision Metal Removal with Accurate Control

Cutting is a process that removes excess material step by step by applying force to the workpiece with a cutting tool, achieving the required size and shape. Common cutting methods include turning, milling, and drilling. Especially in scenarios requiring high precision, cutting can provide very fine machining results.

Advantages of Cutting:

Wide Application Range: It can process materials of various hardness levels, with particular adaptability to metal materials.

High Precision Control: With precision tools and equipment, cutting can meet very strict requirements for size and shape.

Excellent Surface Quality: Cutting can produce a very smooth surface, reducing the need for subsequent surface treatment.

Common Applications:

High-precision shaft components

Precision gears and mechanical structural parts

Aerospace and automotive components

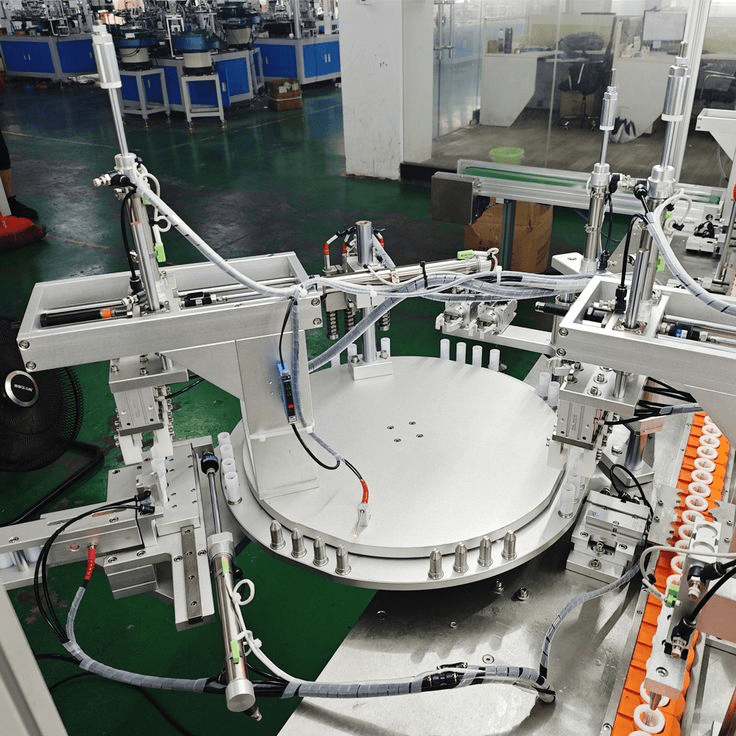

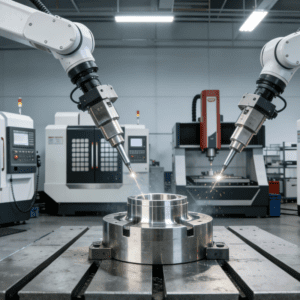

Electrical Discharge Machining (EDM): A Solution for Hard-to-Machine Materials

Electrical Discharge Machining (EDM) is a precision machining method that removes material by using the high-temperature effect of electric sparks generated between an electrode and the workpiece. It is widely used in the production of hard-to-machine materials and complex-shaped parts, especially suitable for processing metals with high hardness.

Advantages of EDM:

Processing of High-Hardness Materials: EDM can effectively process high-hardness and high-toughness metals such as tool steel and alloy steel.

Complex Shapes: It can process complex and fine holes, small structures, and micro-contours.

High Precision: It offers extremely high machining accuracy, achieving micrometer-level dimensional precision.

Common Applications:

Machining of precision molds

Fabrication of complex parts in the aerospace field

Processing of electrodes and conductive tools

Laser Cutting: High-Speed and Precise Non-Contact Machining

Laser cutting technology uses a laser beam to locally heat the workpiece to its melting or vaporization point, and blows away the molten material with high-pressure airflow to form a cut surface. Thanks to its high precision and high speed, laser cutting has been widely used in precision machining.

Advantages of Laser Cutting:

High Precision: Laser cutting can achieve very high cutting accuracy, even down to the micrometer level.

Non-Contact Machining: As a non-contact process, it avoids the effects of mechanical force and reduces workpiece deformation.

Fast Machining Speed: Compared with traditional mechanical cutting methods, laser cutting is faster and suitable for mass production.

Common Applications:

Cutting and forming of precision parts

Machining of small components in the electronics industry

Machining of high-precision metal parts in the aerospace field

3D Printing: Additive Manufacturing Technology with High Flexibility

3D printing (additive manufacturing) is an emerging technology in the field of precision machining in recent years. It forms parts by stacking materials layer by layer according to computer-designed drawings. It breaks through the limitations of traditional machining methods and is particularly suitable for manufacturing complex structures and small-batch customized products.

Advantages of 3D Printing:

High Flexibility: It can produce extremely complex geometric shapes, including internal cavities and complex structures that are difficult to achieve with traditional machining methods.

Tool-Free: Compared with traditional machining methods, 3D printing does not require molds or tools, reducing manufacturing costs.

Advantages in Small-Batch Production: It is suitable for customized and small-batch production, especially in the product development and prototype manufacturing stages.

Common Applications:

Prototyping of complex structures

Personalized customization of medical devices

Fabrication of parts in the aerospace field