On November 13th, Keli Sensing (Stock Code: 603662) held the 2025 Q3 Earnings Conference. During the conference, the company’s management provided detailed answers to investor concerns, covering topics such as the operating results in the first three quarters, the core layout of humanoid robot sensors, technological advantages, and market expansion.

Data shows that in the first three quarters of 2025, Keli Sensing achieved an operating income of 1.082 billion yuan, a year-on-year increase of 17.72%; the net profit attributable to shareholders of listed companies reached 254 million yuan, a year-on-year increase of 33.29%. The dual growth in revenue and net profit demonstrates the effectiveness of the “Sensor Forest” strategy and the layout in the robot track.

Stable Performance Growth, Initial Results of the “Sensor Forest” Strategy

As one of the world’s largest manufacturers of steel sensors and a national-level demonstration enterprise for single-item champions in the manufacturing industry, Keli Sensing maintained a high-quality development momentum in the first three quarters of 2025. The double-digit growth in revenue and net profit stems from the company’s in-depth implementation of the “Sensor Forest” strategy — focusing on four major business segments: intelligent industrial measurement and control, smart logistics equipment, energy and environmental equipment measurement, and robot sensors, while continuously expanding sensor categories and application scenarios.

Currently, the company has deployed nearly 20 types of sensors, including weighing sensors, photoelectric sensors, water quality sensors, optical fiber temperature sensors, light curtains, gas sensors, displacement sensors, electrical quantity sensors, temperature-humidity-pressure sensors, flow sensors, 3D vision sensors, laser ranging sensors, vibration sensors, and robot multi-dimensional force sensors. These sensors have been deeply applied in industrial Internet of Things scenarios such as smart logistics, intelligent warehouses, and mine geophysical exploration. For instance, its sensors have been successfully integrated into the Vibrating Tray for Iron Washers in intelligent manufacturing applications, leveraging precise vibration sensing and displacement detection to ensure the automation and high-precision operation of iron washer assembly — a typical example of how its sensing solutions support efficient product assembly in smart factories. This business structure — “consolidating the basic market in traditional advantageous fields + developing robot sensors as a new growth driver” — not only ensures performance stability but also opens up broad space for long-term growth.

Breakthrough in Humanoid Robot Sensors, Prominent Large-Scale Advantages

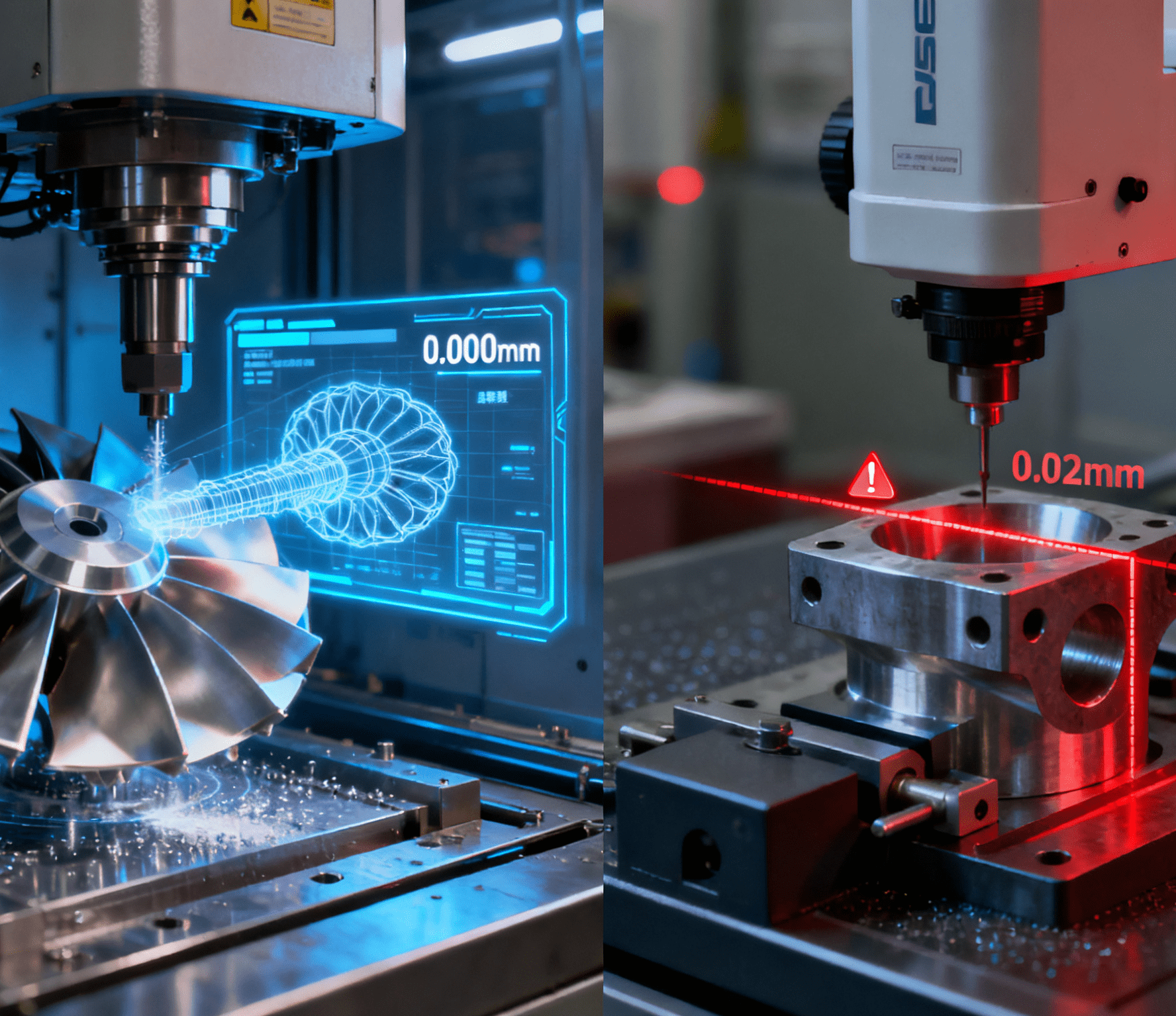

Regarding the layout of humanoid robot sensors, a topic of high concern to investors, Ke Jiandong, Chairman and General Manager of the company, stated at the conference that in terms of 6-axis force sensors (which may be used in humanoid robots), the linear accuracy of the company’s 6-axis force sensors is better than 0.3% FS, and the crosstalk accuracy is better than 2%.

The technical routes, processes, and ADC acquisition used in 6-axis force sensors all belong to the mechanical sensor technology that Keli is good at. Keli has a very mature technical foundation and a sound R&D team. At the same time, the company has independent design and production capabilities in strain gauges, elastic bodies, acquisition modules, and packaging testing, which can significantly control product costs, quality, and customized development cycles. It also has experience in fully automated production of mechanical sensors. Ke Jiandong emphasized: “Compared with competitors, Keli has a significant advantage in large-scale mass production, and the larger the production volume, the more obvious the advantage.”

In terms of customer expansion, Ye Fangzhi, Director, Deputy General Manager, and Secretary of the Board of Directors of the company, revealed that up to now, the company has provided samples to more than 50 domestic enterprises engaged in humanoid robots, collaborative robots, and industrial robots. The products cover key components such as 6-axis force/torque sensors and joint torque sensors. Among them, nearly 1,000 sets of 6-axis force sensors have been shipped, and some customers have moved from sample verification to the small-batch order stage. The product performance and reliability have been recognized by the market.

In addition, the company’s automated testing and machining equipment for 6-axis force sensors has been put into use, realizing fully automated calibration and testing. This has significantly improved product accuracy, consistency, and production efficiency, providing a guarantee for subsequent large-batch delivery. Samples have passed customer testing and orders have been delivered; however, there are no mass production orders yet. The company will adjust production capacity in a timely manner according to industry development and customer needs.

Industrial Investment and M&A, Building a Sensor Ecological Barrier

Keli Sensing’s layout in the robot business is not limited to a single product breakthrough, but rather a full-stack ecological construction centered on “full-body sensors for robots”. In the first half of 2025, the company completed strategic investments in Kepler Humanoid Robots (a humanoid robot body enterprise), Tashan Technology and Yuansheng Xianda (tactile sensor enterprises), and Wuxi Beiwei Sensing (a leading enterprise in inertial measurement units – IMU).

Ke Jiandong stated that through the above layout, the company has achieved full coverage from robot bodies to underlying key mechanical sensing components, and initially built a robot sensing solution capability centered on 6-axis force/torque sensors and integrating multi-modal perception capabilities such as tactile sensing and IMU. This lays a solid foundation for participating in the competition of the entire humanoid robot industry chain in the future. At the same time, the company is steadily advancing investments and mergers in the field of industrial multi-physical quantity sensors, further enriching its product matrix and technical routes, and continuously strengthening its leading position in traditional advantageous fields such as industrial measurement and control, smart logistics, and energy metering.

Looking forward to the future, Ke Jiandong pointed out that the company will continue to promote strategic investments to build a “sensor industry forest”. Adhering to the strategy of “more focused, deeper cultivation, more systematic, and longer-term”, the company will advance investments in the sensor industry, focusing on the implementation of a systematic layout around the core industrial chain of humanoid robots.

Keli Sensing is determined to become a leading domestic enterprise in the integration of multiple sensors and strive to be among the core global suppliers of full-body sensors for robots. This earnings conference not only demonstrated the company’s outstanding performance in the first three quarters of 2025 but also conveyed its firm layout and clear strategy in the field of humanoid robot sensors. With the accelerated development of the humanoid robot industry and the company’s continuous breakthroughs in technology and market, Keli Sensing is expected to continue leading the sensor and industrial Internet of Things track and bring long-term value returns to investors.

Assembly machines suitable for the assembly of various products in