Flexible Vibratory Feeder: Revolutionizing Precision Parts Handling in Smart Manufacturing

In the era of Industry 4.0, where manufacturing demands shift toward multi-variety, small-batch production and high-precision assembly, traditional vibratory feeders—once reliable workhorses for parts orientation—face significant limitations. Their rigid design struggles with irregularly shaped, delicate, or fragile components, often causing surface damage, orientation errors, or lengthy changeover times. Enter the flexible vibratory feeder—a cutting-edge solution integrating adaptive vibration control, intelligent vision systems, and modular design to address the pain points of modern precision manufacturing. This article explores its technical architecture, industrial applications, and role in enabling agile production lines.

- Core Technology: Redefining Parts Orientation through Flexibility

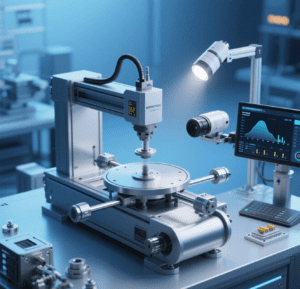

A flexible vibratory feeder transcends conventional linear or bowl feeders by combining multi-directional vibration patterns with real-time adaptive control, creating a dynamic platform that can handle thousands of part types without mechanical reconfiguration. Its core components include:

- Multi-Axis Vibration Generation System

Powered by electromagnetic or piezoelectric actuators, the feeder bed generates precise vibration vectors in X, Y, and Z axes (and even rotational motion), allowing parts to “dance” across the surface in controlled trajectories. Unlike traditional feeders with fixed vibration angles, this technology enables adjustable parameters such as amplitude (0.1–5mm), frequency (20–200Hz), and vibration mode (linear, spiral, or random), adapting to parts ranging from tiny screws (0.5mm) to complex die-cast components (100mm).

- Vision-Guided Positioning & Sorting

Integrated with high-resolution industrial cameras (5MP+), structured lighting, and AI-powered image processing (e.g., deep learning-based part recognition), the system achieves sub-millimeter positioning accuracy (±0.2mm). As parts move on the vibrating bed, the vision system:

- Identifies part orientation, defects (e.g., scratches, misalignment), and positional data in real time

- Sends instant feedback to the vibration controller to adjust motion patterns, ensuring only correctly oriented parts advance to the pick-up zone

- Rejects non-conforming parts via air ejectors or mechanical deflectors, maintaining a 99.9% orientation success rate for complex geometries

- Smart Control Software

The feeder’s digital twin, enabled by IIoT (Industrial Internet of Things) and machine learning algorithms, allows:

- Rapid Recipe Management: Store and recall process parameters for different part types (e.g., material, size, weight) in under 30 seconds

- Self-Optimization: Continuously analyze vibration efficiency and part movement data to minimize cycle time (typically 1–3 seconds per part)

- Seamless Integration: Connect to robotic arms, PLCs, or MES systems via standard protocols (EtherCAT, Profinet), enabling fully automated material flow

- Industrial Applications: Solving Complex Parts Handling Challenges

- Electronics Manufacturing: Delicate Components with Zero Defect

In consumer electronics assembly (e.g., smartphones, wearables), where parts like micro-switches, connectors, and camera modules are tiny (≤5mm) and prone to scratches, flexible vibratory feeders offer decisive advantages:

- Gentle Handling: Low-amplitude vibration combined with anti-static bed coatings protect gold-plated contacts or glass components from damage

- Mixed Parts Sorting: Efficiently separate and orient similar-looking parts (e.g., 0402 vs. 0603 SMD resistors) with 99.5% accuracy

- High Mix, Low Volume: Support rapid product iterations, reducing changeover time from hours (with traditional feeders) to minutes

Case Study: A leading TWS earphone manufacturer reduced component damage by 80% and shortened production changeover by 70% after adopting flexible feeders for handling 3mm ceramic capacitors.

- Medical Device Production: Sterile Environment & Precision Compliance

For medical parts such as syringe needles, orthopedic screws, and micro-fluidic chips—where cleanliness, biocompatibility, and traceability are critical—the feeder’s design features include:

- FDA-Compliant Materials: Stainless steel 316L bedplates and food-grade coatings for easy sterilization (autoclave or UV)

- Contamination Control: Sealed vibration modules prevent particle generation, meeting ISO 8 cleanroom requirements

- Lot-Specific Traceability: Record every part’s orientation timestamp and vibration parameters for regulatory audits

- Automotive & Aerospace: Complex Geometries and High Throughput

In these sectors, parts like turbocharger blades (with intricate aerodynamic shapes), connector pins (with asymmetrical features), or aerospace fasteners (titanium alloys requiring scratch-free handling) pose traditional feeder challenges. Flexible vibratory feeders excel by:

- Adaptive Trajectory Planning: Generate custom vibration patterns for parts with undercuts, holes, or uneven surfaces

- High-Speed Processing: Achieve throughput of 200+ parts per minute for medium-sized components, while maintaining orientation accuracy

- Die-Cast Defect Detection: Integrate with X-ray or 3D vision to identify casting flaws during the feeding process

III. Competitive Advantages Over Traditional Feeders

| Feature | Traditional Vibratory Feeder | Flexible Vibratory Feeder |

| Part Geometry Support | Regular shapes (e.g., screws) | Complex, irregular, fragile |

| Changeover Time | 30–60 minutes | <5 minutes (recipe-based) |

| Damage Rate | 0.5–1% (for delicate parts) | <0.05% |

| Orientation Accuracy | 95–98% | 99.9%+ |

| Connectivity | Isolated operation | IIoT-enabled, MES-integrated |

| Total Cost of Ownership | Lower initial cost, high downtime costs | Higher upfront investment, 40% lower TCO over 5 years |

- Future Trends: Toward Autonomous Parts Handling

- AI-Driven Predictive Maintenance

By analyzing vibration motor temperature, energy consumption, and part flow data, machine learning models can predict component wear (e.g., spring fatigue, actuator degradation) 72 hours in advance, reducing unplanned downtime by 60%.

- Collaborative Robotics Integration

Paired with cobots (collaborative robots) equipped with force-torque sensors, flexible feeders enable “pick-and-place” cells that adapt to human-robot shared workspaces, ideal for hybrid assembly lines in electronics and medical device industries.

- Sustainable Design Innovations

Developments focus on energy-efficient actuators (reducing power consumption by 30%) and recyclable bedplate materials, aligning with global ESG (Environmental, Social, Governance) manufacturing standards.

- Micro-Parts Handling Revolution

For components below 1mm (e.g., MEMS sensors, nanoscale connectors), advanced vibration control combined with electrostatic levitation technology is being tested, promising orientation accuracy within ±0.05mm.

Conclusion

The flexible vibratory feeder represents a pivotal shift in parts handling—from rigid, one-size-fits-all solutions to intelligent, adaptive systems that mirror the complexity of modern manufacturing. By bridging the gap between high-precision orientation and rapid changeover, it empowers factories to thrive in the era of mass customization, where agility and accuracy are non-negotiable. As Industry 4.0 progresses, these feeders will evolve into autonomous smart devices, seamlessly integrated with digital twins and cloud-based production networks, driving the next wave of efficiency in precision manufacturing.

Keywords: Flexible Vibratory Feeder, Precision Parts Handling, Adaptive Vibration Control, Vision-Guided Orientation, Smart Manufacturing Equipment, Multi-Axis Vibratory System, IIoT-Enabled Feeder, Delicate Component Handling, Rapid Changeover Technology, Industrial Automation Solution

#Automate Parts Feeding with Vision System #Paindlik vibratsioonisöötja #apid Changeover Technology