Table of Contents

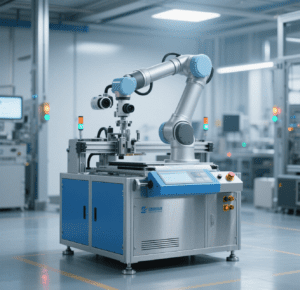

ToggleRobot Vision Positioning Automatic Film Applicator Machine: Reshaping the Intelligent Production Paradigm of Precision Lamination

In high-end manufacturing sectors such as consumer electronics, automotive manufacturing, and medical devices, film lamination is a critical process determining product appearance quality and functional stability. From optical protective films for mobile phone screens to anti-glare coatings for automotive dashboards, and from sterile isolation films for medical devices to insulating films for new energy vehicle batteries, the precision and efficiency of film lamination directly impact the yield rate and market competitiveness of end products. Traditional manual lamination relies on operational experience, suffering from issues like large precision fluctuations, low efficiency, and severe material waste, which can no longer meet the “zero-defect” and “flexible” requirements of intelligent production. As a product of deep integration of industrial automation and machine vision technologies, the Robot Vision Positioning Automatic Film Applicator Machine is redefining the technical standards of precision lamination through accurate positioning, intelligent 贴合 (lamination), and full-process control.

I. Core Technical Architecture and Intelligent Lamination Principles

The Robot Vision Positioning Automatic Film Applicator Machine is a complex intelligent equipment integrating machine vision positioning systems, high-precision robot motion control, flexible lamination actuators, and intelligent industrial control systems. Its technical architecture can be broken down into three core modules:

1. Vision Positioning System: The “Intelligent Eye” with Millimeter-Level Precision

Equipped with high-precision industrial cameras (resolution ≥ 5MP) and multi-angle ring lights, combined with AI-driven vision algorithms (such as Halcon deep learning defect detection and OpenCV feature matching), it realizes real-time scanning of workpiece position, angle, and surface curvature. The system supports dynamic positioning compensation: even if the workpiece has a position offset of ±5mm or an angle deviation of ±3° on the conveyor belt, it can still adjust the lamination path in real-time through visual feedback, ensuring a lamination precision of ±0.1mm—far exceeding the ±1mm error of manual operation.

2. Robot Motion Control System: The “Precision Arm” for Flexible Lamination

Using 6-axis collaborative robots (e.g., ABB YuMi, UR10e) or SCARA robots (e.g., Epson LS6), combined with force control sensors and adaptive trajectory planning algorithms, it achieves three-dimensional collaborative control of “pressure-speed-position” for films. For curved surface lamination (e.g., automotive curved screens, arched mobile phone back covers), the system can automatically generate lamination trajectories. Through the flexible deformation of end effectors (such as silicone pressure heads or vacuum adsorption arrays), it eliminates bubbles and wrinkles caused by workpiece curvature, increasing the lamination yield rate to over 99.8%.

3. Intelligent Industrial Control System: The “Digital Brain” for Full-Process Management

A central control system built based on industrial PCs or PLCs integrates MES data interfaces and OEE real-time monitoring modules, supporting recipe management (storing over 200 lamination process parameters), defect traceability (recording lamination pressure and position coordinates of each film), and remote maintenance (real-time monitoring of equipment status via 5G networks). The built-in AI process optimization model can automatically adjust lamination speed and pressure based on historical production data, reducing the single-station lamination cycle to 3-5 seconds—3 times more efficient than traditional manual operations.

II. Multi-Industry Application Scenarios and Core Advantages

1. Consumer Electronics: Creating “Flawless” High-End Products

In smartphone production, this equipment enables precise lamination of curved screen UV adhesive films, solving the edge bubble problem of 2.5D/3D glass that is difficult to handle manually. In laptop manufacturing, it automatically completes high-speed lamination of keyboard dust-proof films and body logo films, with a single-shift capacity of over 10,000 pieces—50% more efficient than manual lines. Typical case: After a domestic smartphone manufacturer introduced 30 laminators, the lamination yield rate of high-end models increased from 85% to 98.7%, saving over 2 million yuan in material costs annually.

2. Automotive Manufacturing: Tackling Complex Curved Surface Lamination Challenges

For complex curved surfaces such as automotive dashboards, central control curved screens, and headlight lenses, the equipment scans workpiece surface data in real-time through the vision system, driving the robot to complete anti-glare film and thermal insulation film lamination with a “progressive lamination” process (first center positioning, then edge compaction), avoiding film stretching or wrinkling caused by surface curvature. In new energy vehicle battery production, it can precisely laminate insulating films and thermal conductive films for battery casings, meeting IP67 waterproof and thermal management requirements.

3. Medical Devices: Precision Operations in Sterile Environments

In the production of medical endoscopes and in vitro diagnostic equipment, the equipment supports operation in ISO Class 8 cleanroom environments. Through UV sterilization modules and anti-static lamination heads, it realizes lamination of sterile isolation films and electrode protective films, avoiding particle contamination introduced by manual operations. During lamination, the vision system simultaneously detects film edge neatness and bubble rates, ensuring the biocompatibility and functional reliability of medical devices.

Core Advantages Comparison

| Dimension | Manual Lamination | Traditional Mechanical Laminator | Robot Vision Positioning Laminator |

| Lamination Precision | ±1mm | ±0.3mm | ±0.1mm |

| Curved Surface Adaptability | Mainly flat | Small-radius curves | Any 3D curved surface |

| Model Change Time | Over 30 minutes | 15 minutes | 5 minutes (automatic recipe switch) |

| Yield Rate | 80-85% | 90-95% | 99.5%+ |

| Data Traceability | None | Basic parameter recording | Full-process data chain storage |

III. Industry Trends and Technological Evolution Directions

1. Deep Empowerment of AI Vision Technology

Future equipment will integrate 3D structured light scanning and deep learning defect prediction models to realize quality prediction for lamination of special materials such as transparent films and micro-nano films, proactively identifying edge warping risks caused by material ductility differences, and reducing the defect rate to below 0.05%.

2. Upgrading of Flexible Production Capabilities

Through modular design (quick replacement of lamination heads and vision brackets) and adaptive algorithms, the equipment can complete process switching from mobile phone lamination to automotive dashboard lamination within 10 minutes, meeting the needs of multi-variety small-batch production—especially suitable for flexible manufacturing of customized medical devices and high-end consumer electronics.

3. Full-Process Intelligent Integration

Deeply linked with loading/unloading robots, AOI inspection lines, and MES systems, it constructs a closed-loop intelligent production line of “vision positioning-automatic lamination-defect detection-data traceability”. For example, after lamination, the integrated linear array camera can automatically scan film edges, and AI algorithms determine whether re-pressurization is needed, achieving unmanned “detection-correction” operations.

4. Integration of Green Manufacturing Technologies

Developing low-energy vacuum adsorption systems (30% energy consumption reduction) and environmentally friendly glue spraying processes to adapt to lamination needs of degradable film materials, responding to the ESG (Environment, Social, Governance) compliance trends in the global electronics manufacturing industry.

Conclusion

The Robot Vision Positioning Automatic Film Applicator Machine is not just a production device but a key hub for the intelligent transformation of precision manufacturing. Through technological innovation, it breaks through the precision and efficiency bottlenecks of traditional lamination processes, establishing a “high-precision, high-flexibility, high-reliability” production paradigm in high-end manufacturing fields such as consumer electronics, automotive, and medical. With continuous breakthroughs in AI, 3D vision, and industrial internet technologies, this equipment will further evolve toward “self-perceiving, self-deciding, self-optimizing” intelligent equipment, injecting new momentum into the high-quality development of global manufacturing.

Keywords: Robot Vision Positioning, Automatic Film Applicator Machine, High-Precision Film Lamination, AI-Driven Visual Inspection, 3D Curved Surface Film Sticking, Flexible Film Application System, Smart Factory Film Laying Equipment, Consumer Electronics Film Lamination Equipment, Automotive Dashboard Film Applicator, Medical Device Membrane Mounting System

#Curved Screen Film Applicator for Foldable Phones #Robot Vision Positioning System #UV Adhesive Film Lamination Machine