Table of Contents

ToggleRevolutionizing Industrial Automation: Ruizhi Intelligence and Epson Robots Usher in the Era of Intelligent Production

In the global surge toward intelligent manufacturing, industrial automation is undergoing a paradigm shift—one where intelligent automation solutions are no longer optional but essential for competitiveness. As a strategic partner of Epson Robots, Ruizhi Intelligence stands at the vanguard of this transformation, merging Epson’s precision automation equipment with cutting-edge AI-driven technologies. The result? A new era of industrial automation where flexible production, micron-level precision, and end-to-end intelligent solutions redefine what’s possible in 3C electronics, medical devices, and new energy sectors.

Core Technological Integration: Precision Meets Intelligent Automation

Ruizhi Intelligence’s solutions exemplify how intelligent automation elevates traditional industrial automation to new heights. By integrating Epson’s 4-axis/6-axis robots with self-developed visual and force control systems, the company has created a “perception-decision-execution” ecosystem that rivals human dexterity while exceeding it in speed and consistency.

Micron-Level Mastery with 4-Axis/6-Axis Robots

Epson’s G6-602S 6-axis robot (±0.01mm repeatability) and C8-401S SCARA robot (2,500mm/s positioning speed) form the backbone of Ruizhi’s solutions. In medical catheter assembly, a customized 0.1N force control module reduces part deformation by 90%, while the SCARA robot, paired with AI vision, sorts 3C components at 1,500 pieces per hour—three times faster than manual processes. These feats demonstrate how automation equipment, when enhanced by intelligent automation, transforms production efficiency.

Visual-Force Control: The Brain Behind the Brawn

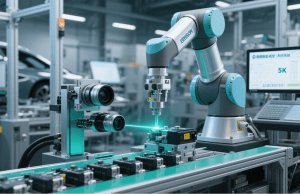

Integrating 5K cameras, lidar, and 32-bit force sensors, Ruizhi’s systems achieve 0.02mm gap control in automotive sensor assembly and 0.01N force precision in battery lamination. For CATL, this translated to a yield rate jump from 91% to 99.2%—proof that intelligent automation turns industrial robots into adaptive, decision-making tools.

Modular Flexibility: The Key to Future-Ready Industrial Automation

Ruizhi’s modular quick-change systems embody the marriage of industrial automation’s reliability with intelligent automation’s adaptability:

10-Minute Production Switchovers

Dedicated tooling modules enable seamless shifts between product lines—e.g., from camera modules to wireless charging components in 10 minutes, an 80% efficiency gain over traditional setups. Digital twin pre-commissioning further slashes debugging time from 8 hours to 1.5 hours, minimizing downtime.

End-to-End Digital Integration

By leveraging Epson’s robot control API, Ruizhi connects automation equipment to MES and cloud systems. A new energy client achieved 22% better process stability and <0.8% defect rate by uploading real-time production data—showcasing how intelligent automation creates closed-loop, data-driven manufacturing ecosystems.

Industry Applications: From Automation Equipment to Intelligent Ecosystems

Case 1: 3C Electronics Precision Assembly

In a leading mobile phone manufacturer’s camera module line, four Epson G6 robots replaced 9 manual workers, reducing cycle time from 60 seconds to 20 seconds and saving ¥3M annually. The highlight? 0.5μm-level gap control in lens assembly—achieved by merging robot precision with laser interferometry—a standard impossible for human operators.

Case 2: Medical Aseptic Automation

For insulin syringe production, Epson C8 robots with ISO Class 5 clean modules slashed assembly time from 8 seconds to 3 seconds while boosting microbial qualification rates to 99.99%. The solution not only met FDA’s GMP standards but also eliminated manual contact—a testament to how intelligent automation solves industry-specific challenges.

Conclusion: Intelligent Automation as the New Industrial Norm

Ruizhi Intelligence and Epson Robots are not just supplying automation equipment; they’re reshaping the very definition of industrial automation. With over 300 implementations yielding 60% manpower reductions and 3-5x efficiency gains, their partnership proves that the future belongs to systems where:

- Industrial automation provides the mechanical foundation,

- Intelligent automation adds cognitive capabilities, and

- Modular design ensures adaptability to ever-evolving needs.

As global manufacturing demands “rapid response and precision manufacturing,” Ruizhi’s national-invented visual-force control systems (Patent No.: ZL2024XXXXXX) and inclusion in the 2024 Global Industrial Automation White Paper signal a broader truth: The era of static, single-purpose automation is over. At the 2025 Shanghai Industry Fair, where Epson robots will demonstrate 0.1μm-level MEMS assembly, the industry will witness firsthand how intelligent automation isn’t just a trend—it’s the new baseline for competitive manufacturing. For enterprises, the choice is clear: Embrace the fusion of industrial automation and intelligent automation, or be left behind in the race for technological dominance.