In the perfume packaging industry, fragmented cap assembly processes (feeding, capping, detection, sorting) often lead to low efficiency, high labor costs, and secondary pollution risks. Ruizhi Intelligent Manufacturing’s integrated perfume cap assembly machine integrates multiple procedures into one, realizing end-to-end automated cap assembly. It breaks the bottleneck of discrete production, bringing efficient, stable, and clean solutions to cosmetic factories.

One Machine for Full Procedures

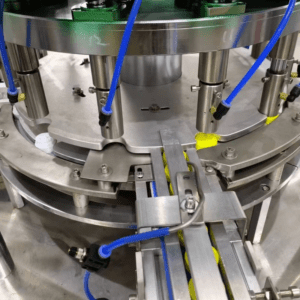

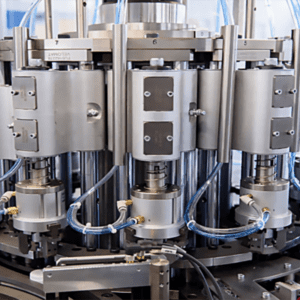

Our integrated equipment integrates cap feeding, automatic alignment, precision capping, sealing detection, and unqualified product sorting in a single unit, eliminating the need for multiple devices and manual transfer. For different cap types (crimp, screw, press), it adapts seamlessly—completing cap picking, positioning, and fitting in one cycle with PLC synchronous control. The built-in in-line negative pressure detection and torque monitoring module instantly identifies leakage or loose caps, automatically rejecting defective products to ensure pass rate. This integrated design reduces production line space occupation by 40% and avoids contamination from manual handling.

Fit Diverse Production Needs

As a non-standard automation expert, Ruizhi customizes integrated solutions for diverse perfume cap specifications (12mm-40mm diameter, glass/plastic/metal materials) and production lines. For luxury special-shaped caps, we optimize visual alignment and clamping structures to prevent scratches; for spray caps, we integrate crimping and valve installation functions. Modular components enable quick mold change within 10 minutes, adapting to small-batch, multi-SKU production. The machine complies with GMP and FDA standards, with 304 stainless steel body and food-grade seals for easy cleaning and sterilization.

Efficiency Upgrade & Seamless Line Integration

With multi-station synchronous operation, the machine achieves a stable output of 40-70 bottles per minute, 3-5 times that of manual assembly, cutting labor costs by over 85%. It supports seamless connection with perfume filling, labeling, and boxing equipment, forming a fully automated packaging line. Ruizhi provides one-stop services: pre-delivery line matching debugging, on-site training, and 24-hour spare parts supply. The equipment’s average trouble-free operation time exceeds 1500 hours, ensuring continuous mass production.

Ruizhi’s integrated perfume cap assembly machine combines process integration, non-standard flexibility, and efficient operation. It helps perfume enterprises streamline production processes, improve packaging quality, and accelerate the intelligent upgrade of their production lines.