In the golden autumn season, the National Day and Mid-Autumn Festival coincide, marking a time of national celebration and family reunions across the country. During the holidays, catering consumption enters a peak period—massive human and logistics flows intersect, food demand surges, and safety risks accumulate accordingly. Ensuring food safety during this period not only tests the enforcement capacity of regulatory systems but also places higher demands on the food industry. Behind this invisible safety line, food machinery and equipment play an irreplaceable role.

The First Gateway to Food Safety: Stable Operation of Cold Chain Systems

High-frequency festival consumer goods such as mooncakes, meat, dairy products, and aquatic products are highly sensitive to temperature. Once the cold chain is broken, the speed of microbial growth accelerates, and foodborne risks rise sharply. Today, cold chain equipment has formed a complete network, covering cold storage in processing enterprises, refrigerated trucks for urban logistics, and freezers in supermarkets and catering terminals. Advanced refrigeration technology, constant temperature control systems, and temperature anomaly alarm devices build a safety barrier for food during transportation and storage. Particularly in recent years, the application of intelligent IoT temperature control labels has enabled real-time monitoring and traceability of the temperature curve of each batch of products, truly realizing full-process control from “milk from factory to cup” and “meat from farm to table”.

The Second Barrier for Food Safety: Disinfection and Sterilization

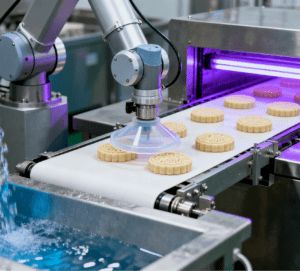

During festivals, the pressure of centralized processing and meal preparation is enormous, and negligence in any link may amplify risks. Automatic disinfection cabinets, ultraviolet sterilization channels, and ozone cleaning equipment are widely used in central kitchens and large-scale food factories, ensuring that containers, tableware, and tools maintain hygiene standards even under high-intensity operation. Meanwhile, CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems on production lines are gradually replacing manual cleaning. These systems can complete cyclic flushing and sterilization of internal pipelines without stopping equipment, reducing downtime and improving the efficiency and reliability of hygiene guarantees.Notably, in the centralized processing of festival-specific foods like mooncakes and layered pastries, the Sheet automatic loading robot has become a key safety link in central kitchens. This robot uses food-grade silicone (negative pressure suction cups) to accurately grasp sheet-like raw materials—such as mooncake crusts, pastry layers, or frozen dough sheets—and automatically conveys them to subsequent processes (like pressing, filling, or baking) at a preset speed of 15-20 sheets per minute. It not only avoids microbial contamination caused by manual contact with raw materials but also ensures that each sheet’s placement error is less than 0.5mm, maintaining uniform product specifications. By linking with front-end disinfection equipment and back-end processing machines, it forms a seamless “disinfection – automatic loading – processing” safety chain, cutting down manual intervention by over 80% while boosting daily processing capacity of festival pastries by 30%.

The Third Key Link: Mechanization and Automation of Food Testing

During festivals, food batches are large and circulation speeds are fast, making traditional manual sampling inspections far from meeting demand. Modern food testing equipment provides technical support for food safety through rapid and accurate on-line monitoring. Metal detectors can identify foreign matter contamination; weight detectors ensure accurate packaging specifications; optical sorting systems use machine vision to remove defective products; and rapid microbial detectors can determine bacterial colony levels within hours. The popularization of these devices has shifted food quality monitoring from post-event remediation to in-process control, intercepting food safety issues at an early stage.

A Delicate Balance: Speed and Safety in Catering Terminals

It is impossible to ignore the delicate balance between meal preparation speed and food safety at catering terminals amid the dual-festival consumption boom. Stir-fry robots, intelligent steam ovens, and multi-functional disinfection dishwashers are rapidly gaining popularity in large catering enterprises and chain restaurants. These devices not only improve meal preparation efficiency but also reduce human errors through standardized procedures, avoiding food risks caused by irregular operations. Especially during peak holiday hours, automated equipment ensures the unification of efficient supply and food hygiene.

Beyond Standalone Equipment: System Synergy and Data-Driven Management

The role of food machinery in ensuring festival food safety is not limited to standalone equipment, but more prominently reflected in system synergy and data-driven management. Today, more and more food machinery can connect with systems such as MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), and LIMS (Laboratory Information Management System). Data on temperature, pressure, disinfection, and testing during production are uploaded to regulatory platforms and enterprise backends in real time. In this way, food safety is no longer an “invisible” process but a dynamic management with verifiable records and traceable trails. Regulatory authorities can access records when necessary, and enterprises can identify potential risks in advance through big data analysis to achieve preventive management.

Festival food safety is a systematic project that requires not only institutional guarantees from the government and self-regulatory management from enterprises but also technical support from food machinery. From cold chains to disinfection, from testing to cooking, from standalone machines to integrated systems, food machinery and equipment form an invisible safety chain, closely linking the reunion dining tables of hundreds of millions of families with the capabilities of modern industry.

It is foreseeable that with the further development of intelligent and digital technologies, the role of food machinery in ensuring food safety will become even more prominent. In the future, more equipment with intelligent sensing, automatic adjustment, and big data analysis functions will enter food enterprises and catering terminals, building a more solid bottom line for food safety.

The festival dining table reflects the warmth of thousands of households and serves as a “conscience test paper” for the food industry. Food machinery, with its silent operation, guards the safety and peace of mind in every bite. During the joyful moments of National Day and Mid-Autumn Festival, these invisible “guardians” stand as the most solid guarantee for the holidays.