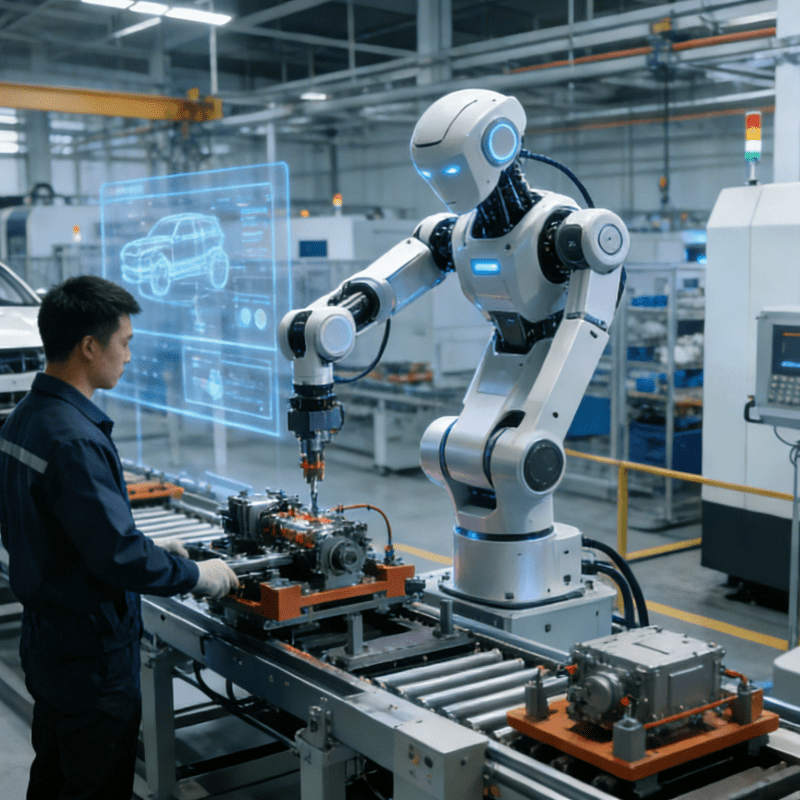

Modern manufacturing is undergoing profound transformation, with its core driving force lying in the deep integration of intelligent programming technology and high-efficiency cutting processes. As a key carrier of this integration, smart machining has significantly improved the intelligence level of the machining process by introducing core technologies such as adaptive path optimization, five-axis simultaneous precision control, and real-time monitoring systems. This in-depth integration not only directly brings a leap in machining efficiency but also maximizes material utilization, profoundly interpreting the core competitiveness of smart manufacturing. It represents a shift from traditional manufacturing to a high-level manufacturing model characterized by data-driven decision-making, real-time response, and resource optimization.

Integration of Intelligent Programming and High-Efficiency Cutting

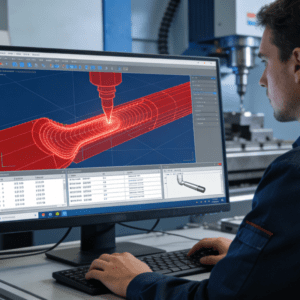

In the field of modern manufacturing, the deep integration of intelligent programming technology and high-efficiency cutting processes is emerging as a key link in driving the leap in smart machining efficiency. The core of this integration lies in the use of advanced algorithms to enable the programming process to deeply understand and accurately respond to complex machining requirements and material characteristics. Intelligent programming systems dynamically generate optimized cutting paths and process parameters by real-time analysis of workpiece geometry, tool performance, and preset targets. This adaptive control capability not only greatly reduces the links dependent on manual experience judgment in traditional programming but, more importantly, lays a precise and reliable foundation for subsequent high-efficiency cutting. Through this in-depth process collaboration, intelligent programming ensures that every tool movement acts on the material in the most scientific way, providing an intelligent solution for achieving the goals of speed, stability, and low loss pursued by high-efficiency cutting.

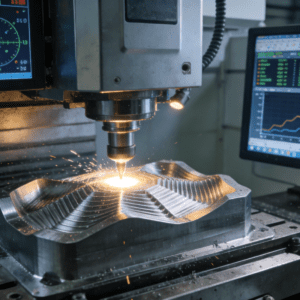

Analysis of Core Technologies in Smart Machining

The core technological breakthroughs in modern smart machining are concentrated in the coordinated operation of its highly intelligent control systems and precision execution units. Five-axis simultaneous machining technology forms the basis for machining precision complex curved surfaces. Through multi-axis coordinated movement, it significantly expands the machining freedom and range of workpieces, enabling high-precision cutting of multiple surfaces and angles in a single setup. At the same time, adaptive path optimization algorithms play a key role. The system can dynamically adjust the feed rate, cutting depth, and tool path in real-time during the machining process based on tool status, material characteristics, and cutting force feedback, effectively avoiding the risks of vibration, overload, or excessive tool wear. Notably, this technological synergy is also fully embodied in specialized equipment such as the automatic spring white disc machine: the intelligent programming system customizes optimized cutting paths for the precise machining of spring white discs, while the real-time monitoring system tracks key parameters such as cutting force and tool wear during the machine’s operation, ensuring the consistency and precision of product dimensions. Supporting the stable operation of all these is a full-process real-time monitoring system. This system integrates a multi-dimensional sensor network to conduct millisecond-level monitoring and analysis of spindle load, temperature changes, vibration spectrum, and tool wear status, providing a solid guarantee for the stability and safety of the machining process. The deep integration of these core technologies has jointly promoted a significant improvement in machining efficiency and finished product quality.

Optimization of Efficiency and Material Utilization

In the smart machining process, the dual optimization of efficiency improvement and material saving has become a key goal. Through the application of intelligent programming technology, the system achieves adaptive path optimization and dynamically adjusts tool paths, effectively reducing idle tool time and increasing machining efficiency by more than 30%. Meanwhile, the combination of high-efficiency cutting processes and five-axis simultaneous precision control ensures high-precision machining and minimizes material waste. The real-time monitoring system continuously detects the machining status, promptly identifies deviations and makes corrections, further ensuring that material utilization reaches an optimal level and providing solid support for smart manufacturing.

Core Competitiveness of Smart Manufacturing

The core competitiveness of smart manufacturing is by no means a simple accumulation of individual technologies, but rather the multiplier effect released by its deep integration and dynamic optimization capabilities. Specifically, it is reflected in the manufacturing process’s ability to significantly improve production efficiency and reduce energy consumption through precise real-time decision-making and adaptive adjustments. More importantly, it achieves the ultimate optimization of resources, pushing material utilization to new heights and effectively controlling overall operating costs. The resulting millisecond-level response mechanism ensures that the production system can agilely respond to complex changes, raising quality stability, delivery punctuality, and cost control to levels unattainable by traditional manufacturing. This comprehensive advantage based on data-driven and flexible execution is the key to modern manufacturing’s success in fierce competition.

The deep integration of intelligent programming and high-efficiency cutting, through the adaptive path optimization and five-axis simultaneous precision control of smart machining, has significantly improved machining efficiency and material utilization. The real-time monitoring system ensures the stability of the production process with millisecond-level response. This technological collaboration not only optimizes resource allocation but also strengthens the core competitiveness of smart manufacturing, providing solid support for the efficient and sustainable development of modern manufacturing.