Biological indicators are essential for sterility verification in medical, pharmaceutical, and laboratory fields, with diverse specifications, complex structures, and strict requirements on assembly precision and sterility. Standard assembly equipment often fails to match personalized production needs, becoming a bottleneck for manufacturers. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, focuses on custom non-standard biological indicator assembly machines, tailoring high-quality, flexible automation equipment to help global customers solve assembly pain points and improve production efficiency.

Adapting to Diverse Biological Indicator Types

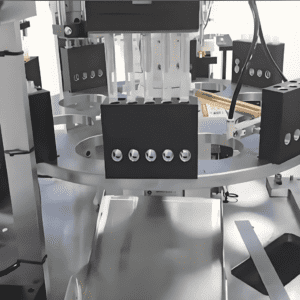

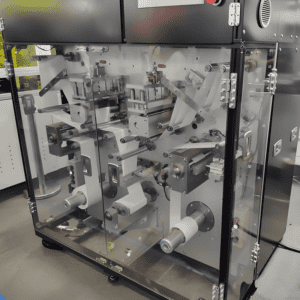

Biological indicators vary widely, including self-contained, steam, dry heat, and ethylene oxide types, with different sizes, assembly sequences, and component structures. Ruizhi’s custom non-standard biological indicator assembly machine is designed according to customers’ specific product parameters and production scenarios. We optimize module configuration, design special fixtures, and adjust assembly procedures to perfectly match different types of biological indicators, supporting flexible switching between multi-specification products and avoiding the limitation of standard equipment on production diversity.

Guaranteeing Assembly Quality and Sterility

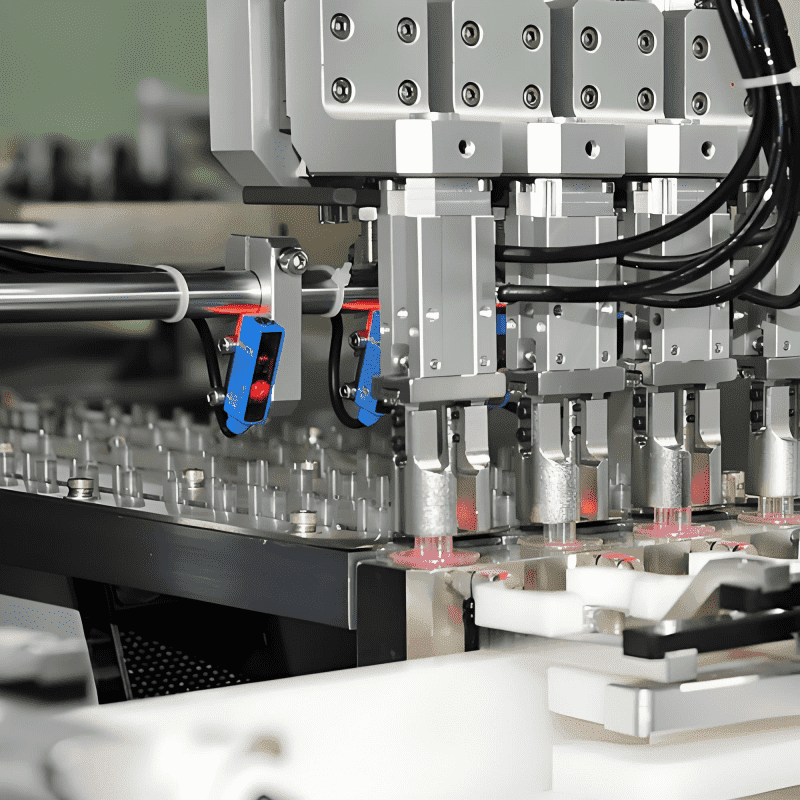

The accuracy and sterility of biological indicator assembly directly affect sterility testing results. Ruizhi’s custom non-standard assembly machine adopts advanced servo positioning and intelligent vision inspection technology, controlling assembly error within ±0.03mm, fully complying with ISO 13485 and GMP standards. The closed assembly environment and dust-free operation avoid contamination, while real-time detection modules identify defects such as component misalignment and poor sealing, ensuring every finished product meets medical-grade quality requirements and eliminating potential risks caused by manual errors.

Matching Custom Production Capacity

Different manufacturers have varying production scales and on-site space constraints. Ruizhi’s non-standard customization service fully considers these factors, designing equipment with adjustable production speed and modular structure to match small-batch trial production or large-batch mass production. The machine integrates automatic feeding, assembly, inspection, and sorting, replacing 8-10 manual positions, improving production efficiency by 2.5 times, and reducing labor costs. Additionally, it supports later function upgrades, adapting to customers’ product iteration needs and extending equipment service life.

Ruizhi Intelligent Manufacturing adheres to the concept of “customization for demand, quality as the core.” Our custom non-standard biological indicator assembly machine combines flexibility, precision, and efficiency, providing personalized automation solutions for global medical and pharmaceutical manufacturers and empowering intelligent production upgrades.

How to choose a multi-component capping assembly machine suitable for your production line?