Table of Contents

Toggle6-Axis Robotic Spring Pick-and-Place System: Mastering Precision in Elastic Component Handling

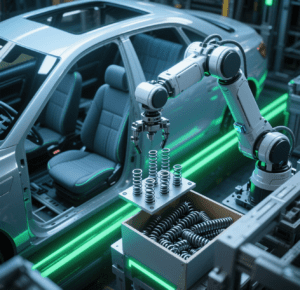

In industries where tiny, elastic components dictate product performance—think automotive suspensions, electronic switches, or medical device actuators—handling springs is a delicate dance of force, precision, and adaptability. Manual pick-and-place operations struggle with inconsistent grip force (leading to deformation or slippage), while 4-axis robots falter with 3D orientation challenges. Enter the 6-Axis Robotic Spring Pick-and-Place System—a versatile solution engineered to tackle these complexities. By combining full 3D dexterity, intelligent force control, and adaptive vision, this system transforms spring handling from a high-risk bottleneck into a streamlined, error-free process.

Why 6-Axis? The Imperative for Elastic Component Dexterity

Springs are inherently complex: their coiled geometry, varying wire diameters (0.1mm to 5mm), and elastic properties demand 6 degrees of freedom (6DOF) for optimal manipulation. Here’s why 6-axis robots outperform alternatives:

1. Unlimited 3D Orientation Control

Unlike 4-axis SCARA robots (limited to planar motion), 6-axis arms rotate freely around all axes, enabling:

- Angled Grasping: Pick springs from tilted trays or vertical magazines at precise angles (e.g., 30° to align with a coil’s pitch).

- Twist-Free Placement: Orient compression springs with ±0.5° rotational accuracy to avoid pre-load errors in assembly.

2. Force-Sensitive Manipulation

A payload capacity of 2–10kg (depending on arm model) combined with 6-axis force-torque sensing lets the robot:

- Apply 0.1–5N of grip force for delicate 0.2mm-thick watch springs.

- Handle heavy-duty automotive suspension springs (1kg+) without deformation.

3. Complex Path Planning

Navigates tight spaces between tooling or fixtures using advanced inverse kinematics, critical for high-density spring storage racks.

Core Technologies: The Backbone of Precision Spring Handling

1. 3D Vision with Deep-Learning Inspection

A stereo vision system paired with AI algorithms solves the chaos of spring orientation and defect detection:

- Chaotic Bin Picking: Identifies nested or overlapping springs in bulk bins, even for identical-looking compression/torsion springs, with 99.8% accuracy.

- Real-Time Feature Analysis: Measures spring height, coil pitch, and wire diameter in milliseconds, rejecting defective parts (e.g., misshapen coils or uneven ends) before handling.

Example: In a micro-spring factory, the system distinguishes between 0.3mm and 0.5mm wire diameter springs in a mixed bin, eliminating manual sorting.

2. Adaptive Gripping with Force Feedback

The end effector is a marvel of customization:

- Compliant Grippers: Soft rubber jaws conform to spring contours, preventing marring on plated surfaces (common in consumer electronics).

- Magnetic-Electric Hybrid Tools: Use adjustable electromagnets for ferrous springs and vacuum suction for non-magnetic variants (e.g., titanium alloy springs in aerospace).

- Force-Torque Sensor Integration: Maintains grip force within ±0.05Nduring pick-and-place, critical for preventing over-compression of delicate extension springs.

3. AI-Optimized Motion Planning

Machine learning algorithms continuously refine the robot’s path to:

- Minimize Spring Swing: Predict and counteract elastic oscillations during high-speed movement (e.g., reducing swing from 2mm to 0.2mm for 10mm-long springs).

- Avoid Collisions: Navigate around adjacent springs in dense trays using real-time 3D mapping.

Transforming Industries: Applications in High-Stakes Spring Handling

1. Electronics: Micro-Spring Assembly in Switches

In a smartphone button factory, where 0.5mm-thick torsion springs must align with ±0.03mm precision:

- The robot picks springs from a 1000-unit feeder tray using vision-guided precision.

- Places them into plastic switch housings with 0.1° rotational accuracy, eliminating misalignment that causes button stickiness.

Result: Defect rate drops from 15% (manual) to 0.8%, and cycle time per switch reduces from 12 seconds to 4 seconds.

2. Automotive: Heavy-Duty Suspension Spring Loading

For a car suspension plant handling 500g compression springs (100mm height, 20mm wire diameter):

- Robust mechanical grippers with anti-slip coatings securely hold springs during transport to CNC machines.

- Vision system checks for surface cracks or uneven coils, integrating with MES to flag defective batches.

Case Study: A Tier 1 supplier achieves 99.5% first-pass yield, saving $3M annually in scrap and rework.

3. Medical Devices: Precision Spring Placement in Syringes

In insulin pen manufacturing, where 2mm-long extension springs require sterile handling:

- Sterile-grade grippers and stainless-steel tooling meet ISO 13485 standards.

- Force control ensures springs are compressed to exactly 80% of their free length during assembly, critical for consistent injection force.

6-Axis vs. Traditional Methods: A Performance Showdown

| Metric | 6-Axis Robotic System | Manual Handling | 4-Axis Robot | Pneumatic Picker |

| 3D Orientation Control | Yes (6DOF) | Limited (2–3DOF) | No (4DOF) | No (2DOF) |

| Force Control Accuracy | ±0.05N | ±0.5N (variable) | ±0.2N (planar only) | ±1N (fixed pressure) |

| Cycle Time (small spring) | 2–3 seconds | 10–15 seconds | 5–6 seconds | 8–10 seconds |

| Defect Rate | <1% | 10–15% | 5–8% | 3–5% |

| Changeover Time (new spring type) | <20 minutes | 60+ minutes | 40 minutes | 120+ minutes |

The Business Case: From Elastic Challenges to Tangible Gains

1. Rapid ROI Driven by Quality and Speed

- Labor Savings: Replaces 2–4 operators per line, saving $60k–$100k annually in labor costs (especially in high-wage regions).

- Yield Improvements: Reduces spring deformation and misplacement errors by 90%, critical for applications where 0.1mm misalignment causes product failure.

- Scalability: Handles 24/7 production with 98% uptime, supported by predictive maintenance (e.g., alerts for gripper wear or joint backlash).

2. Future-Ready Flexibility

- Multi-SKU Adaptability: Stores 100+ spring profiles in its database, enabling quick 切换 between compression, torsion, and extension springs with zero manual programming.

- IoT Integration: Feeds real-time data (grip force, cycle times, defect locations) to factory analytics platforms, enabling predictive quality control.

The Evolution of Spring Handling: Where Dexterity Meets Intelligence

As industries demand smaller, more complex springs (e.g., micro-coils for MEMS devices or variable-rate springs for electric vehicles), the 6-axis system evolves with:

- Self-Calibrating Tools: On-tool sensors auto-detect spring dimensions, eliminating setup time for new part numbers.

- AI-Powered Defect Prediction: Uses historical data to anticipate spring deformation risks based on material type and handling speed.

- Collaborative Safety: Equipped with 3D safety scanners, works alongside human technicians in shared workcells—ideal for R&D prototyping or low-volume custom spring production.

In a world where the performance of entire systems hinges on the precision of tiny springs, the 6-Axis Robotic Spring Pick-and-Place System is not just an upgrade—it’s a necessity. It turns the inherent challenges of elastic component handling into a competitive advantage, empowering manufacturers to achieve new levels of quality, speed, and flexibility.

#6Axis Spring Handling #Robotic Spring Assembly #Precision Pickand Place System