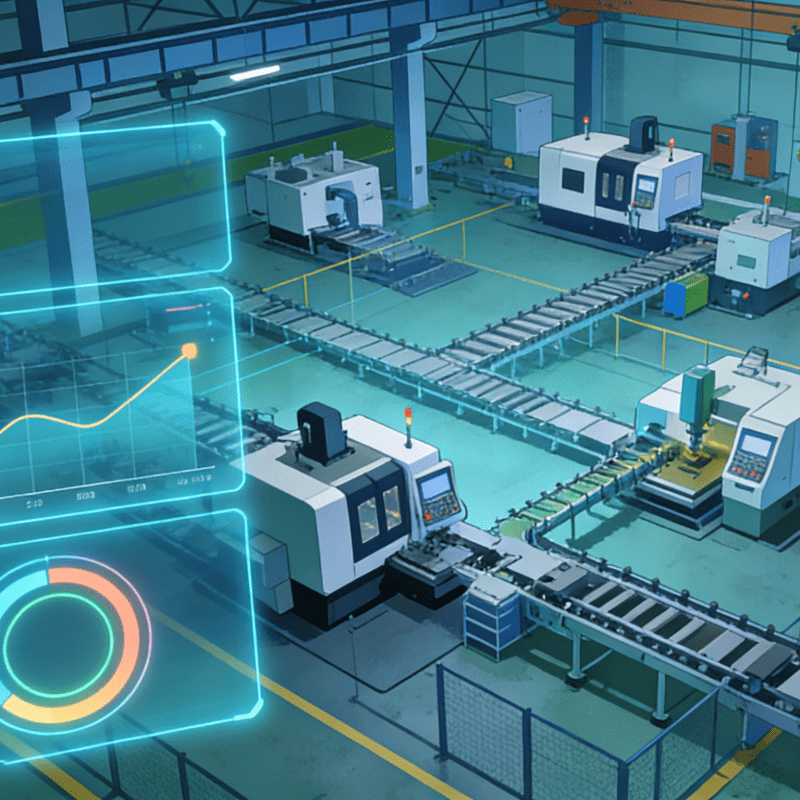

In today’s rapidly evolving manufacturing sector, 3D printing and intelligent machining stand as two core digital manufacturing technologies, each boasting unique advantages and application scenarios. Understanding their fundamental differences is crucial for engineers, designers and procurement decision-makers alike. This paper delves into the key distinctions between these two technologies in practical applications, particularly in two common and critical stages: prototyping and low-volume production. By analyzing their respective working principles, material adaptability, cost structures and processing efficiency, we clearly outline the optimal selection path for different demand scenarios. This helps readers make more informed and efficient technological choices based on core factors such as cost, time, precision and complexity when faced with specific projects.

A Comparison of 3D Printing and Intelligent Machining Application Scenarios

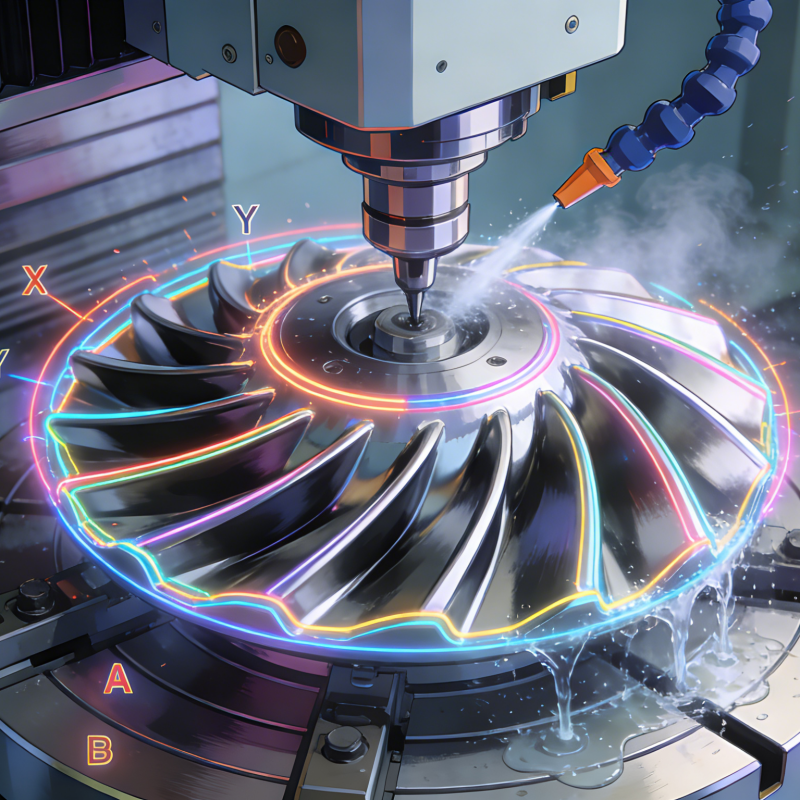

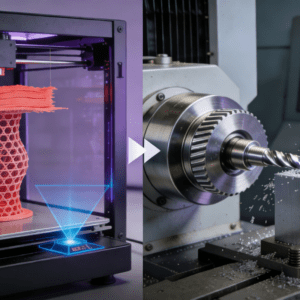

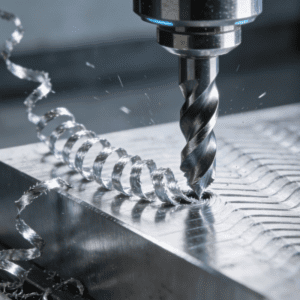

In the manufacturing industry, 3D printing and intelligent machining are two mainstream technologies with distinctly different application scenarios. 3D printing constructs objects by stacking materials layer by layer, making it particularly suitable for processing designs with complex geometric shapes, such as the rapid iterative modeling in the prototyping phase. In contrast, intelligent machining relies on cutting tools to remove excess material, and is better suited for occasions demanding high precision and robust structural strength. This divergence makes 3D printing superior in terms of flexibility and cost-effectiveness, while intelligent machining delivers more reliable performance in large-scale production. Next, we will explore their specific performance in prototyping and low-volume production in depth.

Advantages and Disadvantages of Prototyping Technologies

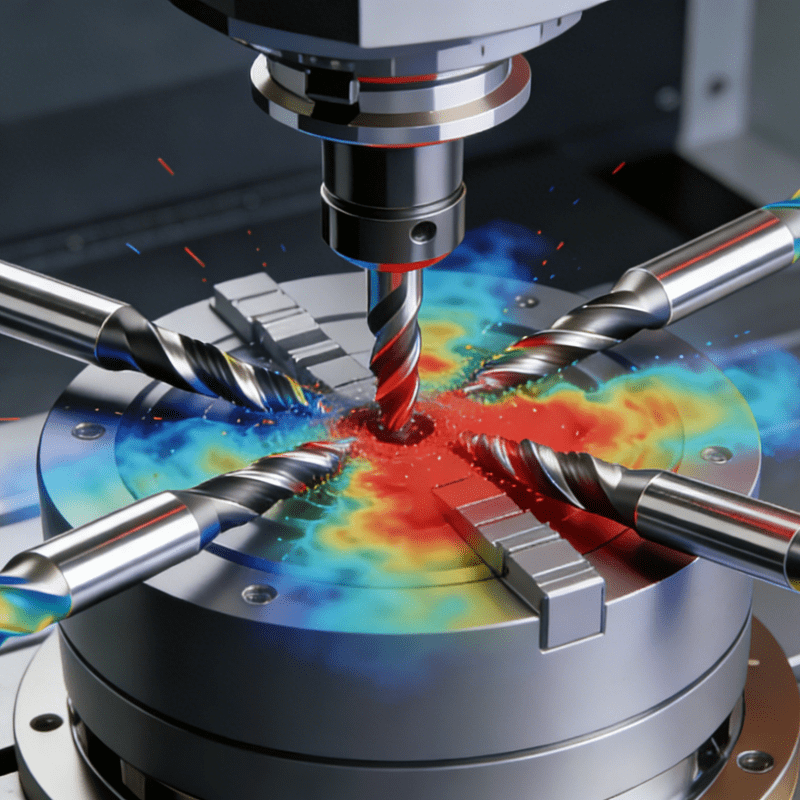

The prototyping phase highlights obvious differences between 3D printing and intelligent machining. 3D printing technology stands out for its rapid prototyping capability: designers only need to import digital models into the equipment, and physical prototypes can usually be obtained within a few hours or one to two days, greatly shortening the development cycle. This method excels at processing complex geometric shapes and internal structures that are difficult to achieve with traditional machining. Meanwhile, it generates minimal material waste and incurs relatively low costs, making it ideal for early design verification and frequent design iterations. However, the surface finish and dimensional accuracy of 3D printed prototypes may sometimes fall short of intelligent machining, especially for components requiring tight fit or high surface smoothness. On the other hand, intelligent machining produces prototypes by precisely cutting raw materials (such as metals or engineering plastics). Its advantage lies in the ability to create prototypes with performance extremely close to the final finished products, featuring outstanding dimensional accuracy, superior surface quality and a wide range of material options. This makes intelligently machined prototypes more advantageous when rigorous functional testing, mechanical load bearing or simulation of the final production environment is required.

Analysis of Low-volume Production Selection

When production demand escalates to the low-volume stage (usually referring to tens to hundreds of units), the choice between 3D printing and intelligent machining becomes even more critical. 3D printing demonstrates unique advantages in this field: it completely eliminates the cost of expensive molds, making it particularly suitable for producing customized parts with complex geometric shapes and frequent design iterations, such as personalized medical device components or limited-edition product accessories. Even for a production run of one unit or fifty units, its unit cost usually remains stable, which is highly suitable for exploratory market launch or highly customized orders. Nevertheless, for parts required to withstand high strength, high wear resistance or extreme temperatures, 3D printed parts made of traditional materials may be slightly inferior in mechanical performance. In comparison, intelligent machining often delivers better cost-effectiveness in low-volume production, especially for batches ranging from 50 to 500 units. Although its initial setup (programming and fixture preparation) is time-consuming and involves certain costs, the cost allocated to each part drops significantly as production volume increases. Notably, this advantage is fully reflected in the low-volume production of core components for Equipo automático de disposición de bandejas de resorte—such equipment’s key parts (including precision guide rails, positioning pins and transmission shafts) require strict dimensional accuracy and stable structural rigidity to ensure the smooth and accurate automatic arrangement of springs. Intelligent machining can achieve one-stop processing of these parts with high precision, ensuring their assembly accuracy and operational reliability, which is difficult for 3D printing to match in terms of mechanical performance and processing efficiency. Intelligent machining directly uses engineering-grade metal bar stock (e.g., aluminum alloy, stainless steel) or high-performance plastic bar stock, and the finished products feature excellent strength, precision and surface finish. It is thus highly suitable for end functional components with stringent requirements for reliability and durability, such as precision instrument housings or durable mechanical parts. Therefore, the key to selection lies in balancing the part complexity, material performance requirements, budget and production speed expectations.

After comparing the applications of 3D printing and intelligent machining in prototyping and low-volume production, we conclude that there is no absolutely superior technology—it all depends on specific scenarios. For prototyping, 3D printing offers the advantages of rapid iteration and low cost, making it the priority for the design verification stage. Conversely, in low-volume production, intelligent machining is better able to meet strength requirements by virtue of its high precision and material diversity. Therefore, users should make trade-offs based on project needs: prioritize 3D printing if flexibility and speed are pursued; opt for intelligent machining as a more reliable choice if precision and durability are emphasized. Ultimately, the rational matching of technologies can improve production efficiency and control costs effectively.