Basic Knowledge of Robotic Systems

A robotic system is a complex intelligent machine designed to make our lives easier and more efficient.Let’s break it down and explore what a robotic system really is:More than just a fancy machine: A robotic system is not merely a single robot performing its tasks. It is a complete interconnected network composed of components that work in collaboration.Powerful yet intelligent: At the core of a robotic system lies the combination of physical capabilities and artificial intelligence. These systems can execute tasks that require both mental and physical effort, often outperforming humans in terms of precision, speed, and stamina.Adaptable problem-solvers: One of the most remarkable features of robotic systems is their ability to adapt and learn, thanks to artificial intelligence (AI) and machine learning. They do not just follow pre-programmed instructions; instead, they can analyze the environment, make real-time decisions, and improve their performance over time.

Types of Robotic Systems

Understanding different types of robotic systems helps you grasp the diversity and functionality of robots across various fields. Let’s dive into the three main types of robotic systems you will encounter:

Autonomous robots: These semi-independent “thinkers” can operate without human intervention. They use sensors, artificial intelligence, and pre-programmed instructions to navigate and perform tasks independently. Examples include self-driving cars and Roombas (robotic vacuum cleaners).

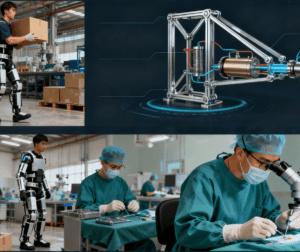

Teleoperated robots: Ever wished you could be in two places at once? Teleoperated robots make this as close to reality as possible. These robots are controlled remotely by humans, usually in real time. They are ideal for exploring hazardous environments or conducting delicate surgeries—scenarios where human expertise is crucial, but direct presence is impossible or unsafe.

Augmenting robots: These robots work alongside humans to enhance our capabilities rather than completely replacing us. They are designed to complement human skills and make tasks easier or more efficient. An example is an exoskeleton that helps factory workers lift heavy objects, or a robotic arm that assists surgeons in complex operations.

The Most Important Components of a Robotic System

A robot is more than just fancy algorithms and sleek designs. At its core, a robotic system relies on the complex interaction of various components working in harmony. Here are the key elements you need to know:

Central Processing Unit (CPU): Just as humans need a brain to function, robots require a Central Processing Unit (CPU) to handle complex calculations and decision-making. The CPU processes sensor data, executes programmed instructions, and coordinates the robot’s movements.

Sensory “organs”: Sensing devices act as the robot’s sensory organs, collecting data about its environment. Ranging from simple touch sensors to advanced vision systems, they help the robot perceive its surroundings and respond accordingly. This is how your robotic vacuum knows to avoid chair legs, or how your smart thermostat detects when you are at home.

Motion actuators: What’s the point of all that processing and sensing if the robot can’t actually do anything? That’s where actuators come in. Actuators work by converting energy into physical motion. Whether it’s a rotating motor, a hydraulic piston that lifts heavy loads, or a tiny servo that precisely positions a robotic arm, actuators enable robots to interact with the physical world.

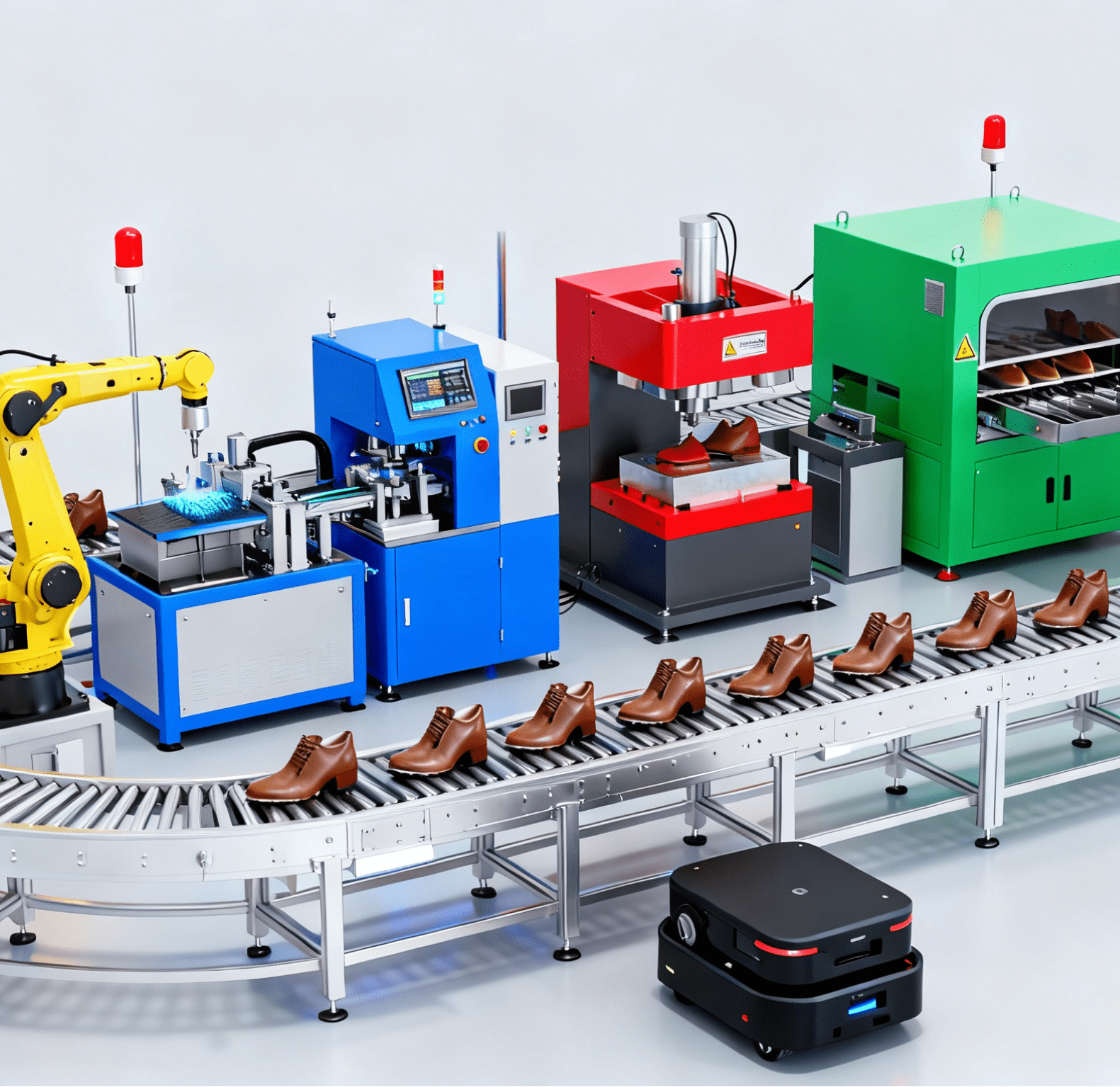

Applications of Robotic Systems in Manufacturing

Robots are incredibly efficient, precise, and tireless workers. Let’s take a closer look at some industries where they are making an impact:

Assembly Lines

Assembly lines are where robots excel, precisely because most tasks here are repetitive. Boring, right? Well, robots never get bored. They can perform these tasks wholeheartedly 24/7. From assembling complex electronic devices to welding car frames, robots are boosting the productivity of assembly lines.

Specialized Medical Manufacturing: Μηχανή συναρμολόγησης βιολογικών δεικτώνs

In the medical manufacturing space, robotic systems play a critical role in powering Biological Indicator Assembly Machines—these specialized setups use high-precision robotic arms (equipped with force-control sensors) and enclosed sterile chambers to assemble biological indicators (tools used to verify the effectiveness of sterilization processes in hospitals and labs). The robotic systems ensure ultra-accurate placement of microbial cultures and components, while maintaining a contamination-free environment—critical for avoiding errors that could render the indicators unreliable, as their performance directly impacts medical sterilization validation.

Packaging

Robots are highly skilled at packaging products of all shapes and sizes—from tiny microchips to bulky furniture. They can seal, label, and package items faster than you can blink, while maintaining consistent quality. Unfortunately, you’ll still have to deal with the bubble wrap when your Amazon order arrives.

Advantages of Using Robotic Systems

Whether you run a small business or manage a large company, robotic systems can transform your operations. Here are the top three advantages of robotic systems:

Increased work efficiency: Imagine having a tireless worker who never needs a coffee break or a day off. That’s what robotic systems offer. These mechanical wonders can work around the clock (24/7), producing products or performing tasks at a speed that would make even the most caffeinated human dizzy. You’ll be amazed at how quickly you can boost output and leave your competitors behind.

Safer workplaces: Let’s face it—some jobs are extremely dangerous. But with robotic systems, you can keep your human workers out of harm’s way. These metal guardians can handle hazardous materials, work in extreme temperatures, or perform repetitive tasks that cause injuries. Your workplace safety record will shine brighter than a freshly polished robot—and your employees will be much more grateful for it.

Exceptional precision: If you’ve ever tried threading a needle after having a few cups of coffee, you know how tricky precise work can be. But for robots, it’s just another day at the “office.” They can complete tasks with impressive accuracy, consistently delivering results that even the steadiest human hand would envy. This minimizes human error and significantly increases the chances of achieving perfect outcomes.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine