Dual-Holiday Dining Peak Pressure: Why Traditional Methods Fall Short and Smart Equipment Steps In

This year, the National Day holiday coincides with the Mid-Autumn Festival, bringing both “crowds of people” and “waves of diners” almost simultaneously. In restaurants on the street, patrons waiting in line at the door watch the busy scene in the kitchen, all hoping that their steaming hot dishes will be served soon. For those in the catering industry, this is not just a holiday business boom, but also a test of “speed” and “quality”. The old methods of hiring more staff or extending working hours can no longer cope with the holiday peak. Only by letting smart equipment “step up” can the warmth of home-style cooking remain uncompromised and diners return with satisfaction.

Diverse Smart Gear: Upgrading Efficiency from Stir-Frying to Meal Prep

In the past, a common sight was: chefs sweating profusely from busyness, while the front hall was filled with constant reminders for orders. The emergence of smart stir-fry machines has turned this passive situation around. These machines convert heat control, ingredient addition, and stir-frying rhythm into precise parameters. Instead of relying on a chef’s “sense of touch”, they stably produce dishes based on preset process curves. A single machine can operate multiple woks at the same time, ensuring that each dish is cooked and served at a consistent pace. For diners, this means less anxious waiting; for chefs, it means less exhaustion from physical overexertion.

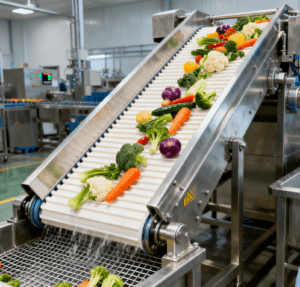

Of course, stir-fry machines are not the only “saviors”. Dishes frequently ordered during holidays—such as steamed dishes, grilled meats, and fried foods—can all be prepared in batches using combined steaming and roasting ovens or pressure fryers. These devices not only preserve the color and taste of the food but also shorten waiting times. Even in the ingredient pre-processing link, the flexible automatic loading and unloading vibrator has become a hidden efficiency booster: its adjustable vibration frequency (30-60Hz) and soft food-grade silicone conveyor belt can gently transport ingredients of different sizes (from small enoki mushrooms to large potatoes) without causing bruising or damage, while automatically sifting out tiny impurities like soil particles or broken leaves. It can also be linked with subsequent automatic cleaning or cutting equipment, intelligently adjusting the feeding speed to match the processing rhythm—for example, supplying 5kg of cleaned and sorted vegetables to the cutting machine per minute—reducing manual sorting time by over 50% and ensuring a steady flow of prepped ingredients during peak hours. Automatic noodle cookers and quantitative sauce dispensers turn the uncertainty of “waiting for the pot” into the predictability of a “fixed timeline”. What diners pick up after waiting is not just food, but also the sense of togetherness that should not be delayed during the holiday.

Craftsmanship + Digital Synergy: Building a Dual Defense Line for Efficiency and Quality

Equipment is only the foundation; craftsmanship is the soul. Pre-holiday preparations should not be misunderstood as “pre-made meals”. Instead, they involve scientific pre-processing: ingredients are uniformly cleaned, cut, and marinated, then quickly chilled at low temperatures and vacuum-packed—preserving both flavor and safety. During the holiday peak, restaurants only need to complete the final heating and seasoning steps. Tedious procedures are handled in central kitchens, while the “wok aroma” and freshness are reserved for the dining table. This division of labor ensures that “hot dishes are served quickly and cold dishes are never delayed”, allowing family reunion tables to have less rushing and more ease.

During peak hours, digital technology acts as an invisible “dispatcher”. Systems predict popular dishes based on past orders, reminding restaurants to prepare ingredients in advance. Kitchen display screens break down orders into specific tasks, indicating which dish to prioritize and which tables to combine orders for—preventing chefs from being overwhelmed. Sensors monitor oil temperature and steam pressure in real-time; if anomalies are detected, adjustments are prompted immediately. It is these invisible “helpers” that help catering businesses avoid chaos and maintain order amid the holiday rush.

The True Value of Smart Equipment: People-Centered Catering Upgrades and Industry Insights

Food safety is particularly crucial during holidays. With large crowds and high order volumes, the biggest fear is neglecting hygiene and temperature control due to busyness. Cold chain transportation adheres to “minute-level” warehousing; kitchens use disinfection cabinets and ultraviolet sterilization to maintain cleanliness; during the serving process, time-controlled labels ensure that “hot dishes are not overdue and cold dishes are not expired”. Even at the busiest moments, every dish has a “safety certificate”, allowing consumers to eat with confidence and catering staff to work with peace of mind.

Energy conservation and environmental protection are equally indispensable. Induction cooktops replace open flames, improving efficiency while reducing kitchen fumes. Waste heat recovery from combined steaming and roasting ovens makes energy consumption more controllable. Real-time oil quality monitoring extends the lifespan of cooking oil, stabilizing flavor while reducing waste. For chain catering brands, energy conservation in a single store cuts costs; across the entire network, it builds a positive reputation.

The value of smart equipment is not to replace chefs’ hands, but to free them from physical labor—allowing them to focus on taste and creativity. What diners taste is still the steaming “wok aroma”; it is just more stable and reliable. Chefs are no longer “firefighters” but true “culinarians”.

The dual holidays (National Day and Mid-Autumn Festival) are both a stress test and a capability competition for the catering industry. Whoever can maximize the potential of equipment and weave data and processes into an invisible safety net will win public praise during peak hours. The warmth of home-style cooking needs to be preserved, but it does not have to be at odds with efficiency. The best answer for holiday dining tables is the coexistence of smart equipment and human warmth.

What is the difference between assembly and subcontracting?

How to optimize the assembly process of an assembly machine?