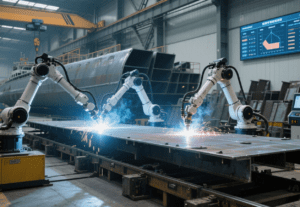

Opening: Practical Value of Baichu Electronics’ Intelligent Welding Systems Verified by Multiple Industry Cases

At present, Baichu Electronics’ intelligent welding systems have accumulated a wealth of customer cases in the application of steel structure welding in industries such as construction, power oil tanks, power transmission towers, ships, bridges, and mechanical equipment. The practical value of its technical solutions has been fully verified.

2025 H1 Financial Report: Revenue and Profit Achieve Double Growth with Stable High Gross Profit Margin

On the evening of August 21, Baichu Electronics released its semi-annual report for 2025. In the first half of the year, the company achieved an operating income of 1.103 billion yuan, representing a year-on-year increase of 24.89% and a quarter-on-quarter increase of 22.65%; the net profit attributable to shareholders of the parent company was 640 million yuan, with a year-on-year growth of 30.32% and a quarter-on-quarter growth of 50.58%; the non-recurring net profit was 594 million yuan, up 25.97% year-on-year; the gross profit margin stood at 78.83%, compared with 80.62% in the same period last year.

Company Profile: A Leading High-Tech Enterprise in Domestic Fiber Laser Cutting Control Systems

Baichu Electronics is a high-tech enterprise and a key software enterprise engaged in the R&D, production, and sales of industrial automation systems. It is also one of the first private enterprises in China to develop complete sets of control systems for fiber laser cutting. As an outstanding system supplier in the domestic laser cutting field, it has been leading the development of new technologies and directions in laser cutting by virtue of its continuous innovation-driven capabilities and rich industry experience.

2025 H1 Market Position: Dominant in Both Low-Medium and High-Power Laser Cutting Markets

In the first half of 2025, Baichu Electronics continued to maintain a leading edge in the domestic low-to-medium power market; in the field of high-power laser cutting control systems, the company firmly held the first place in the domestic market. Although in recent years, some integrators have gradually launched self-developed laser cutting motion control systems and peer enterprises have continuously iterated their products, there is still a gap between these products and Baichu Electronics’ products in key performance indicators such as stability, reliability, and ease of use. Therefore, against the backdrop that integrators lack the willingness to invest heavily in R&D and there is a significant performance gap between peer products, neither of them can pose a substantial threat to Baichu Electronics’ market share in this field.

Laser Cutting Technology Advantages: Software-Hardware Synergy Drives Advanced Automation Functions

In the laser cutting field, Baichu Electronics realizes more advanced automation functions through “software-hardware collaboration and intelligent control”. Through the scanning of special-shaped U-ribs, it helps improve the production efficiency of the bridge steel structure industry; through the cutting of three-sided intersecting holes in round pipes, it optimizes the traditional processing mode of boiler tube rows and further enhances cutting efficiency; it has launched a new generation of intelligent cutting heads, which free workers’ eyes through eagle-eye edge detection and enable one-click activation of fully automatic processing through intelligent boundary sensing; it has also launched a secondary beveling system to achieve intelligent scanning and positioning, allowing one-click beveling of parts.

Laser Cutting Customer Resources: Cooperating with Over 700 Domestic Laser Equipment Manufacturers

Currently, in the laser cutting field, Baichu Electronics has more than 700 domestic laser equipment manufacturer customers and partners, including Han’s Laser, Huagong Farley Laserlab, Hymson Laser, Bystronic-DN, Jiatai Laser, Senfeng Laser, Qingyuan Laser, Hongshi Laser, and Lens Technology.

New Growth Driver: High-Potential Intelligent Welding Field Deserves Attention

In addition to the laser cutting field where it “reigns supreme”, Baichu Electronics’ high-growth intelligent welding field is also worthy of attention.

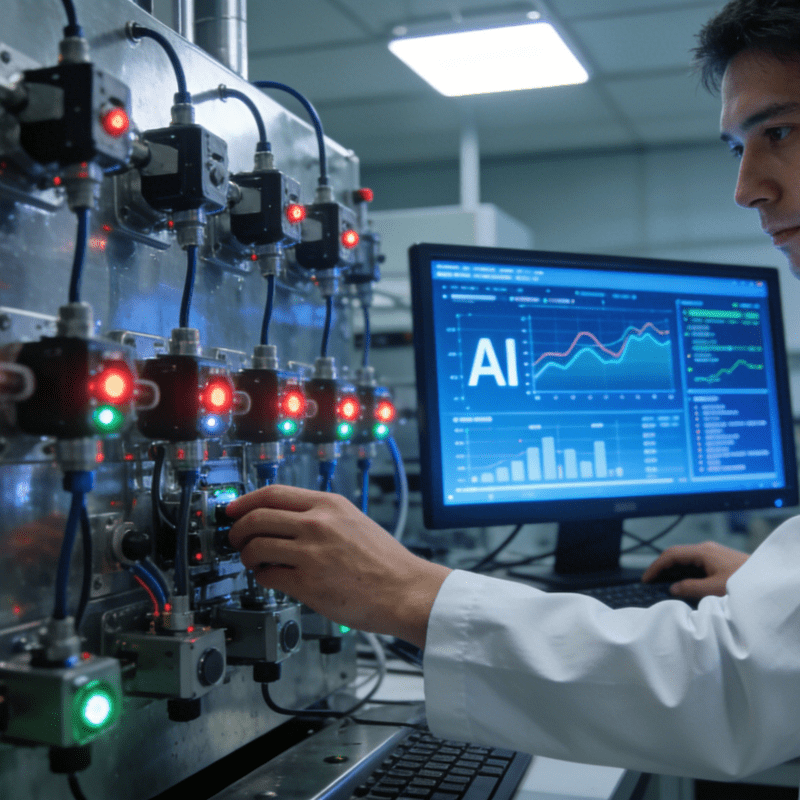

2025 H1 Intelligent Welding Innovations: Multi-Machine Linkage, AI Visual Technology, and Multi-Brand Robot Adaptation

In the first half of this year, Baichu Electronics achieved “genuine” multi-machine linkage planning in this field, supporting automatic task allocation, intelligent obstacle avoidance, and processing of ultra-wide workpieces on large-format workbenches. This effectively supports industries such as shipbuilding and bridge construction, further improving production efficiency and factory utilization. Combined with AI deep learning algorithms, it launched a new generation of high-end visual seam trackers, which have strong anti-interference capabilities and can stably identify features such as welding spots, weld holes, and weld gaps. Highly integrated with multi-visual modules, these trackers are applicable to various types of bevel recognition, enabling pipe-to-pipe butt joint and effectively solving pain points such as difficult processing of narrow welds and camera reflection interference. The company has also completed the adaptation work for robots of more brands, including Fanuc.

Industry Recognition for Intelligent Welding: High Proportion of Exhibitors Adopt Baichu’s Systems at Essen Exhibition

According to incomplete statistics, at the Essen Exhibition two months ago, nearly 20 enterprises exhibited their respective intelligent welding robots or workstations, among which about 15+ exhibitors displayed robots equipped with Baichu Electronics’ intelligent welding systems, accounting for an extremely high proportion. According to relevant sources, in the first half of the year, Baichu Electronics has successively started adapting to the robot bodies of multiple leading industrial robot manufacturers, which also reflects the recognition of leading enterprises in this field for Baichu Electronics from the side.

Market Background for Intelligent Welding: Traditional Manufacturing Pain Points Spur Demand for Teaching-Free Robots

With the accelerated transformation and upgrading of China’s manufacturing industry, traditional manufacturing methods are being gradually replaced. On the one hand, the high work intensity and poor working environment of welders have exacerbated the industry’s difficulty in recruiting workers; on the other hand, the pain points of traditional teaching robots, such as reliance on manual teaching, low efficiency, and complex operation, have become increasingly prominent.

Market Demand for Intelligent Welding: Over 10 Billion Yuan Potential Stock Demand in Steel Structure Industry Alone

Against this background, teaching-free robots rely on visual systems and intelligent welding software to realize workpiece recognition and precise weld positioning, and independently plan welding paths. They have now been widely used in the steel structure industry. If only the steel structure industry is considered, the domestic potential stock market demand for intelligent welding systems is at least over 10 billion yuan.

Intelligent Welding Application and Cooperation: Rich Cases and Strategic Partnerships Lay Solid Foundation

At present, Baichu Electronics’ intelligent welding systems have accumulated rich customer cases in the application of steel structure welding in industries such as construction, power oil tanks, power transmission towers, ships, bridges, and mechanical equipment, and the practical value of its technical solutions has been fully verified. Meanwhile, in recent years, Baichu Electronics has established cooperation with a number of downstream steel structure enterprises. In 2021, it signed intention purchase agreements with Hongyu Heavy Industry, Bafang Steel Structure, and CSCEC Steel Structure; at the end of November 2023, it signed a strategic cooperation agreement in the intelligent welding field with Honglu Steel Structure. Therefore, the intelligent welding system field, as Baichu Electronics’ second growth engine, is the key to its high-speed growth in the future.

New Layout: Expanding into Precision Processing Field with Diversified Solutions

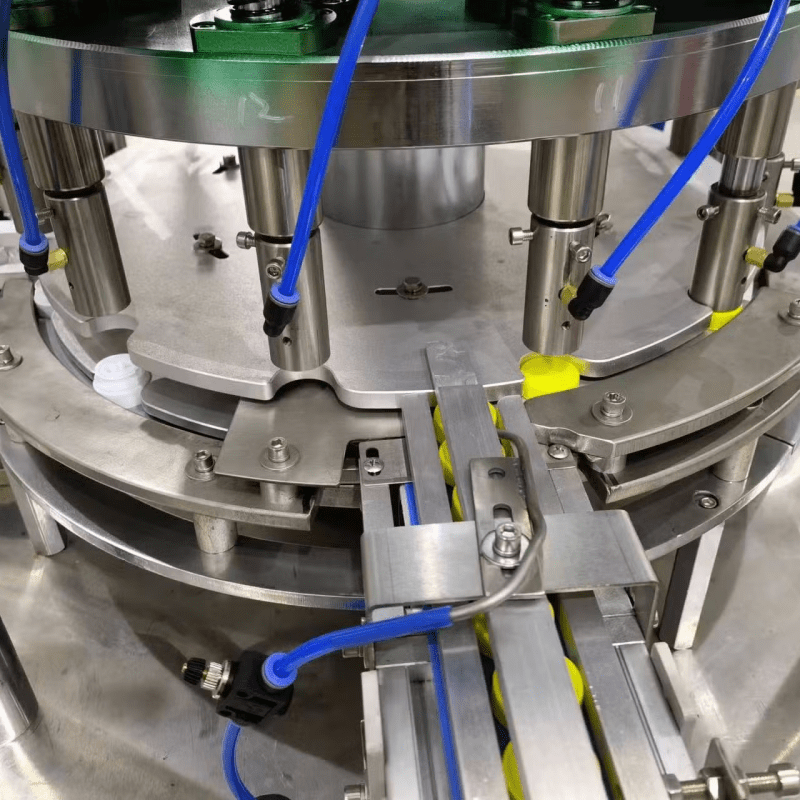

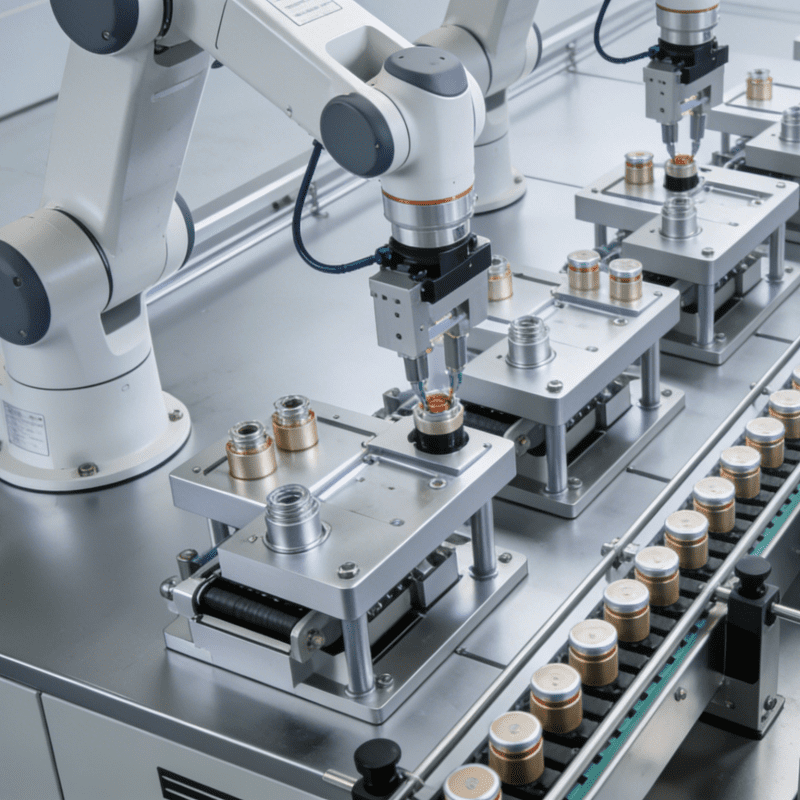

In addition, Baichu Electronics has also made layouts in the precision processing field. It adopts advanced optical coherence technology to measure the optical path difference (penetration depth) of the detection light reflected from the workpiece surface and the bottom of the keyhole, thereby realizing real-time monitoring of penetration depth and quality control during the laser welding process. For the photovoltaic industry, it has launched efficient and accurate laser scribing and laser grooving solutions. With the advantages of high precision, high speed, and high stability, these solutions help the photovoltaic industry reduce costs and increase efficiency, and promote the development of clean energy. At the same time, the company has also developed a supporting automated control module for the Μηχανή συναρμολόγησης περιστροφής. Through precise motion trajectory planning and real-time speed regulation, this module ensures that the equipment achieves millimeter-level rotational positioning stop and synchronous assembly actions during the assembly of products such as electronic precision components and small automotive connectors. This further fills the gap in automated control for segmented scenarios in the precision assembly field and enriches the coverage dimensions of industrial automation solutions.

Conclusion: Multi-Field Expansion and Technological Advantages Drive Stable Development

Based on its first-mover advantage in the laser cutting field, Baichu Electronics is gradually accelerating its penetration into “blue ocean” fields such as intelligent welding and precision processing. Through the vertical deepening of core technological advantages and the horizontal breakthrough in emerging scenarios, the company has demonstrated strong resilience amid economic fluctuations and delivered a satisfactory performance in the first half of 2025.

Assembly machines suitable for the assembly of various products with robot applications