The cosmetics and packaging industry is evolving rapidly, with vacuum bottles becoming a staple for serums, creams, and high-end skincare products—thanks to their airtight design that preserves product efficacy and extends shelf life. However, the industry’s diverse product specifications, varying bottle shapes, and strict quality requirements make generic assembly machines impractical. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing specializes in custom non-standard vacuum bottle assembly machines, tailored to solve the unique challenges of the cosmetics & packaging industry. Below, we explore how our customized equipment empowers enterprises to achieve efficient, high-quality production.

Tailored Design for Diverse Cosmetic Vacuum Bottle Specifications

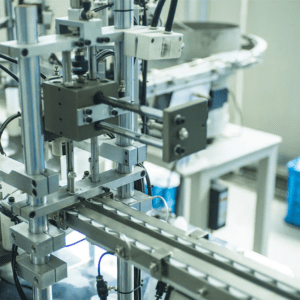

Cosmetic vacuum bottles come in countless sizes (from 5ml to 100ml), shapes (round, square, irregular), and assembly processes (different pump cores, inner plugs, and cap designs)—a one-size-fits-all machine cannot meet these varied needs. Ruizhi Intelligent Manufacturing conducts in-depth communication with customers to understand their specific bottle parameters, production capacity, and assembly requirements. We customize core components such as feeding mechanisms, assembly modules, and gripping tools, ensuring the machine perfectly adapts to different bottle types. This eliminates the need for manual adjustment, reduces downtime when switching product models, and ensures smooth assembly for all cosmetic vacuum bottle specifications.

Industry-Specific Quality Control to Meet Cosmetic Safety Standards

The cosmetics industry has strict safety and quality requirements—even minor assembly defects (such as loose caps, incomplete sealing, or contaminated inner parts) can lead to product waste and brand damage. Ruizhi’s non-standard custom vacuum bottle assembly machine integrates industry-specific intelligent detection functions, including real-time sealing testing, part missing inspection, and surface flaw detection. These functions automatically identify defective products and reject them, reducing defect rates to near zero. We also customize the machine’s operation speed and precision according to cosmetic production standards, balancing efficiency and quality to meet the industry’s strict compliance requirements.

Flexible Integration & Cost-Efficiency for Cosmetic Production Lines

Most cosmetic manufacturers have existing production lines with limited space and specific layout requirements. Ruizhi’s non-standard custom vacuum bottle assembly machine features a compact, flexible design that can be seamlessly integrated with existing feeding, labeling, and packaging equipment. We also optimize the machine’s structure according to on-site space, avoiding the need for large-scale workshop renovations. Additionally, the automated custom machine replaces 70% of manual labor, reduces labor costs, and operates 24/7 without fatigue—helping cosmetic enterprises reduce production costs while improving production efficiency and scalability.

Ruizhi Intelligent Manufacturing understands the unique pain points of the cosmetics & packaging industry. Our non-standard custom vacuum bottle assembly machine combines tailored design, strict quality control, and flexible integration to provide personalized automation solutions. Choose Ruizhi, and let our professional custom equipment empower your cosmetic vacuum bottle production, helping you gain an edge in the competitive market.

How to choose a multi-component capping assembly machine suitable for your production line?