Motion Control Advances Expand Assembly Possibilities

In the realm of industrial automation, the integration of cutting-edge motion control technologies is reshaping assembly processes across diverse sectors—from automotive to medical devices and beyond. Just as Customized Sanitary Ware Assembly Solutions rely on precision and adaptability to meet unique manufacturing demands, advancements in motion control are enabling smarter, more flexible automation systems. Let’s explore how innovations in actuators, controllers, sensors, and emerging technologies like AI are revolutionizing assembly possibilities, with parallels to the tailored solutions driving efficiency in industries like sanitary ware production.

Levitation, often associated with otherworldly phenomena, takes on a pragmatic meaning at Automation NTH. The company’s new flexible assembly machine utilizes a magnetic-levitation (maglev) system to handle disposable blood test kits with precision—a process that mirrors the meticulous adaptability required in Customized Sanitary Ware Assembly Solutions. Here, maglev movers float workpieces on magnetic fields, rotating and tilting them for inspection, reagent dispensing, and sealing with ±30-micron accuracy. This technology eliminates the limitations of conventional indexing systems, where cycle times are dictated by the slowest workstation. Instead, maglev allows independent mover control, enabling dynamic part transfer and “lot-size-one” production—key advantages for industries requiring customization, such as sanitary ware assembly.

The decision to adopt Beckhoff Automation’s XPlanar maglev system was driven by dual needs: operating in a temperature/humidity-controlled cleanroom and handling test kits in random order based on specific reagent recipes. “Smooth motion and environmental compatibility are critical for preserving reagent integrity,” notes Molly Blazek of Automation NTH. This emphasis on precision and adaptability echoes the requirements for Customized Sanitary Ware Assembly Solutions, where components must withstand varied conditions and accommodate unique design specifications. The result? A five-second cycle time per kit—down from five minutes in the manual process—showcasing how advanced motion control can transform efficiency in specialized assembly lines.

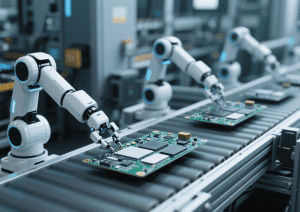

Beyond maglev, motion control advancements are evident in actuators, controllers, and sensors. Integrated direct-drive servomotors from SEW Eurodrive now offer torque density and position control once deemed impossible, while actuators like Afag’s SREH embed controllers and IO-Link connectivity, reducing wiring and cabinet space. “Decentralized design with built-in process monitoring is a game-changer,” says Florent Orget of Emerson. This mirrors how Customized Sanitary Ware Assembly Solutions leverage modular components to optimize space and streamline diagnostics, ensuring seamless integration into complex workflows.

Smart sensors further enhance precision: vibration sensors in spindle drives detect early signs of wear, while force sensors enable delicate assembly tasks. Combined with software tools like digital twins and physics-based modelers, engineers can validate motion sequences virtually, minimizing trial-and-error in physical prototypes—an approach akin to the pre-installation modeling in Customized Sanitary Ware Assembly Solutions to ensure fit and function.

Artificial intelligence (AI) and edge computing are now amplifying motion control capabilities. While AI’s full potential is still unfolding, its role in predictive maintenance—analyzing sensor data to forecast component failures—has already proven valuable. “AI-driven systems can alert teams weeks in advance of potential issues, preventing downtime,” says Eric Falasco of Bosch Rexroth. Adaptive learning algorithms also optimize motion parameters in real time, a feature that could benefit dynamic assembly lines, such as those producing customized sanitary ware components. Edge computing, meanwhile, reduces latency by processing data locally, easing the load on main controllers and enabling real-time adjustments—critical for integrating high-speed vision systems or AI-enhanced quality checks.

As motion control technologies evolve, their impact extends beyond automotive and medical sectors. Just as Customized Sanitary Ware Assembly Solutions thrive on flexibility and precision, industries worldwide are harnessing maglev, integrated actuators, and AI to build assembly systems that adapt to ever-changing demands. The common thread? A focus on customization, efficiency, and future-proofing—whether through floating workpieces on magnetic fields or designing modular assembly lines for unique products. In an era where adaptability is key, motion control advancements and tailored industrial solutions like those in sanitary ware assembly are paving the way for smarter, more resilient manufacturing.