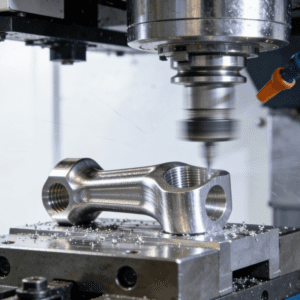

5-axis precision machining centers play an indispensable role in the production of high-precision medical parts. Especially when facing complex-structured, ultra-high-precision medical device components—such as orthopedic implants or core parts of precision surgical tools—traditional machining methods are often inadequate.

The core advantage of such equipment lies in its powerful multi-axis simultaneous motion capability, enabling machining on multiple complex surfaces of a part at the same time. Most processes can be completed in a single clamping setup. This not only greatly reduces the risk of accumulated errors caused by repeated fixturing, but also enables stable and efficient machining of difficult-to-cut materials such as medical titanium alloy and special stainless steel.

It is precisely this high-precision, high-efficiency machining capability that ensures the critical dimensions and surface quality of finished medical parts stably meet strict micron-level requirements, laying a solid manufacturing foundation for the safety and reliability of medical devices.

Key Applications and Advantages of High-Precision Multi-Surface Simultaneous Machining Technology

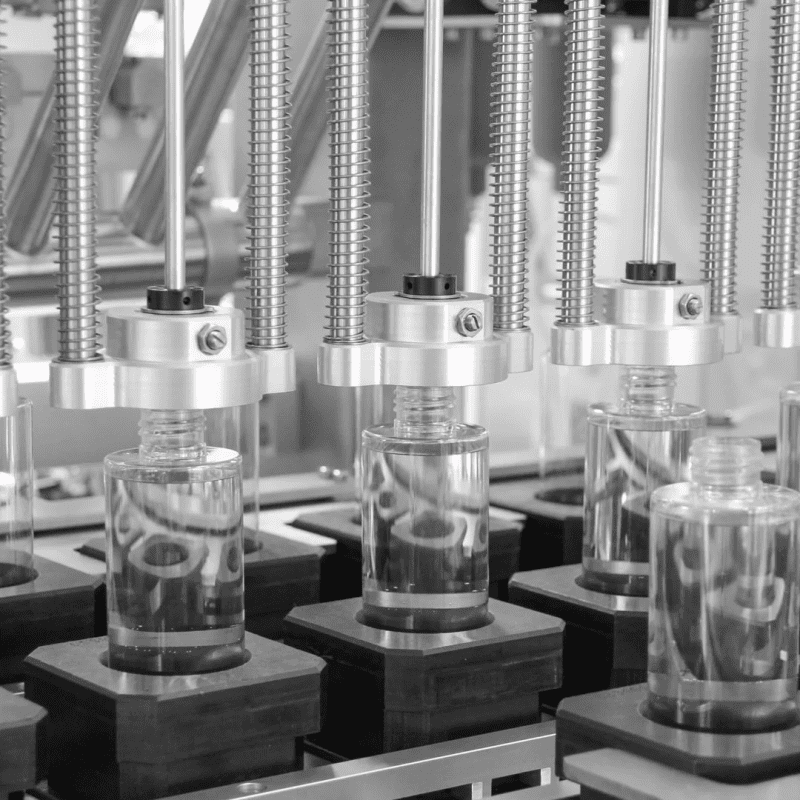

The core strength of 5-axis precision machining centers is their ability to perform precision machining on multiple surfaces simultaneously. Consider a complex medical part, such as an artificial joint or a component of precision surgical instruments. Traditional methods require multiple clamping and machining operations, which are time-consuming and prone to accumulated errors.

With 5-axis technology, the workpiece is clamped once, and the spindle can cut from all angles, eliminating the trouble of repeated positioning. This directly avoids accuracy loss caused by multiple setups and ensures the positional accuracy and overall consistency of all complex surfaces of the part.

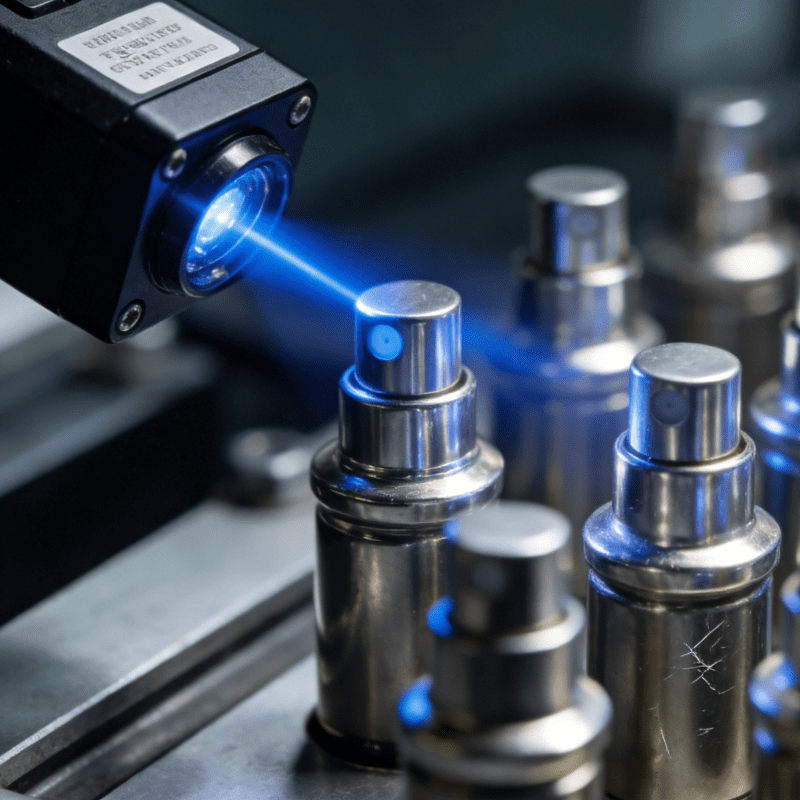

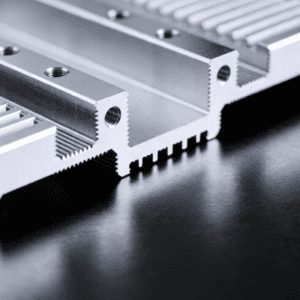

Notably, it performs exceptionally well on difficult-to-machine materials such as titanium alloy and medical stainless steel—materials widely used in the medical field but challenging to process. By precisely controlling tool paths and workpiece posture, 5-axis machining stably achieves micron-level accuracy. This high precision and stability form the basis for meeting strict medical industry standards and ensuring the safety and reliability of implants and instruments.

Achievement of Micron-Level Accuracy Control for Precision Medical Parts and Compliance with Medical Standards

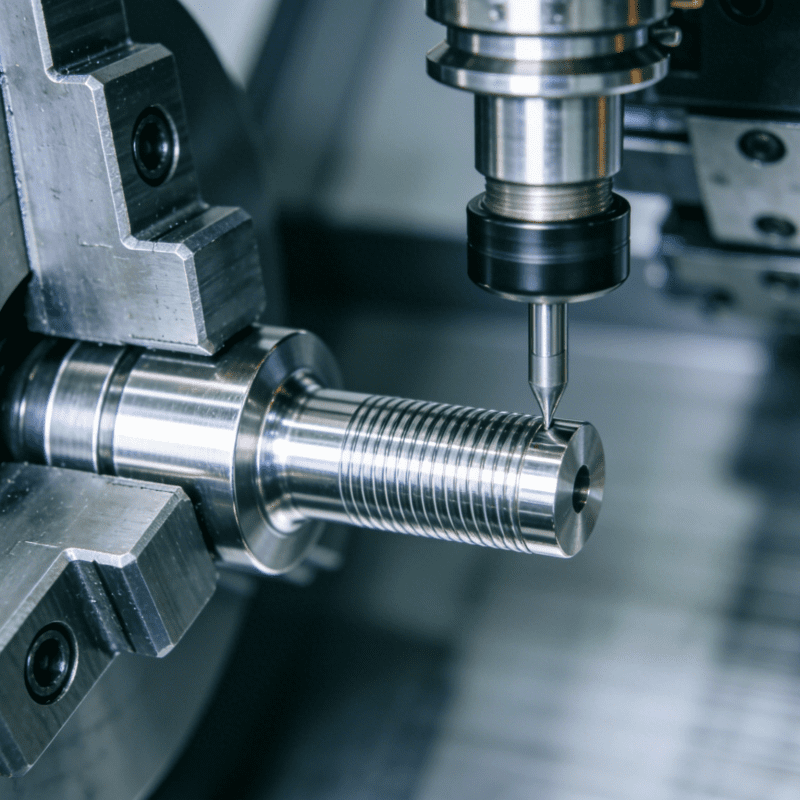

The key to achieving micron-level accuracy for precision medical parts lies in the precise control capability of 5-axis precision machining centers. These machines coordinate multiple motion axes simultaneously and guide tool paths accurately, ensuring every cut meets precision requirements comparable to the thickness of a human hair.

Such precise control is especially critical for key components like titanium alloy joints and complex surgical instruments. It can machine extremely complex geometries while guaranteeing high consistency in dimensional accuracy and surface finish across all surfaces.

Meanwhile, strict process control—including environmental temperature and humidity monitoring and real-time tool wear compensation—provides the foundation for stable micron-level accuracy. All these directly serve strict medical standards such as the ISO 13485 system, ensuring that final implanted components or instruments are absolutely safe, reliable, and fully meet clinical performance requirements.

5-axis precision machining centers demonstrate critical value in the manufacturing of precision medical parts. Through high-precision simultaneous machining and stable control, they ensure parts meet micron-level specifications and directly satisfy stringent medical industry standards.

This technology not only improves the reliability of implants and surgical instruments but also optimizes the entire production flow, providing solid assurance for the safety and clinical performance of medical devices. Ultimately, it drives the development of safer and more efficient medical solutions.