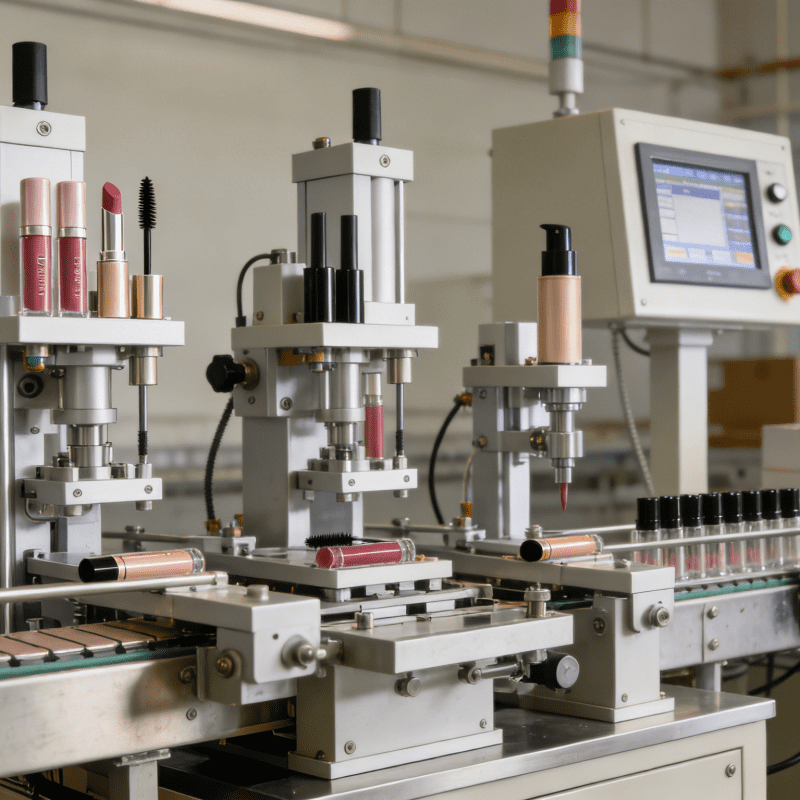

In the fast-paced cosmetics industry, production efficiency directly determines a manufacturer’s market competitiveness. Manual and semi-automatic assembly methods are no longer able to keep up with the growing demand for large-scale production and high-quality standards. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has helped numerous cosmetics enterprises optimize their production processes with advanced cosmetics assembly machines. This article explores three key ways these machines boost production efficiency, bringing tangible value to cosmetics factories.

Higher Production Speed Than Manual Assembly

Manual assembly of cosmetics components—such as lip gloss tubes, mascara wands, and spray pump heads—is time-consuming and prone to fatigue. A single worker can only assemble 30-50 units per minute, while Ruizhi’s automatic cosmetics assembly machines can reach 100-150 units per minute, 3 to 4 times faster than manual work. These machines support 24/7 uninterrupted operation without rest or error due to fatigue, significantly increasing daily output and helping enterprises meet peak production demands quickly.

Reduced Labor Costs and Error Rates

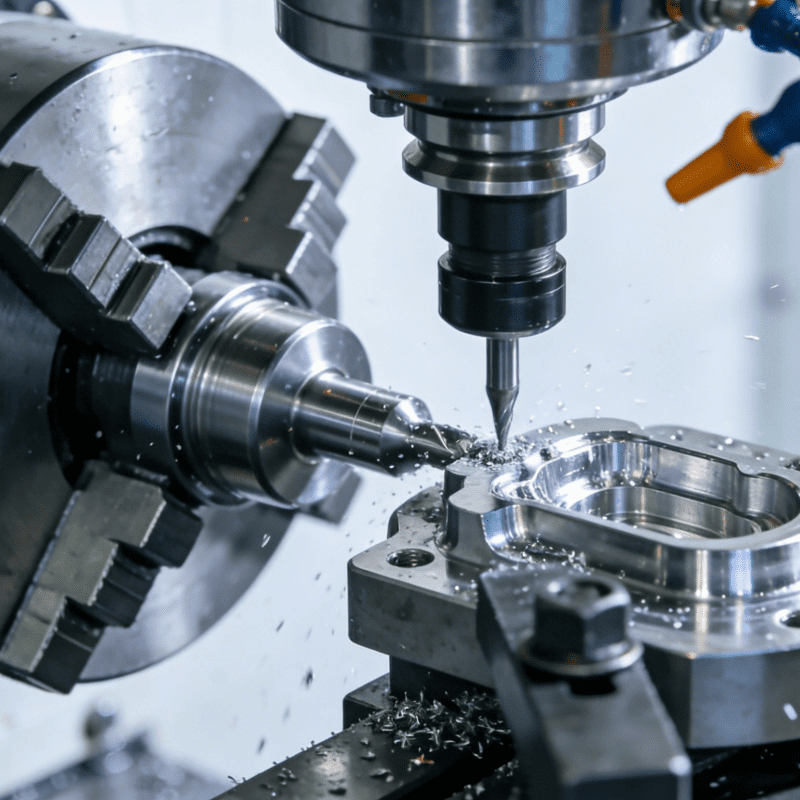

Labor costs account for a large proportion of cosmetics production expenses. Ruizhi’s cosmetics assembly machines can replace 70% of manual labor, reducing the need for a large number of assembly workers and cutting down labor and management costs. Meanwhile, the machines adopt high-precision positioning and intelligent detection technology, which minimizes human errors such as misaligned components and loose assembly. This reduces defective products and material waste, further improving production efficiency and cost-effectiveness.

Flexible Customization for Diverse Production Needs

The cosmetics market features frequent product updates and diverse specifications, requiring flexible production equipment. Ruizhi Intelligent Manufacturing focuses on non-standard automation solutions, allowing our cosmetics assembly machines to be customized according to different product types, sizes, and assembly processes. Whether it’s lip gloss, mascara, or skincare spray pumps, the machines can be quickly adjusted to adapt to new production needs, avoiding the trouble of replacing equipment and saving time for product iteration.

In conclusion, cosmetics assembly machines are essential tools for modern cosmetics factories to improve production efficiency. Ruizhi Intelligent Manufacturing combines professional technology and customized services to provide high-quality, efficient assembly solutions, helping enterprises gain an edge in the fierce market competition and achieve sustainable development.