Electropolishing technology plays a crucial role in modern manufacturing, especially when processing stainless steel parts via CNC machining. Through the chemical action of an electrolyte, this process effectively smooths out micro-defects on the part surface, thereby enhancing its surface finish. Beyond improving aesthetics, electropolishing also excels at boosting corrosion resistance— the protective film formed after treatment can effectively block the intrusion of external corrosive factors, significantly extending the service life of the parts. With this technology, manufacturers can produce stainless steel products that better meet industry standards and boast higher quality, greatly enhancing their market competitiveness.

How Electropolishing Enhances Surface Finish and Corrosion Resistance of Stainless Steel Parts

Electropolishing is an effective method to significantly improve the surface finish of stainless steel parts. Through the action of an electrolyte, the process smooths out micro-depressions and flaws on the part surface, creating a uniform metallic luster. Compared with traditional mechanical polishing, electropolishing can remove impurities more thoroughly and achieve a higher level of surface finish. At the same time, this technology also significantly improves the corrosion resistance of stainless steel parts. This is because a thin film formed on the surface during the electrolysis process can effectively isolate the part from external corrosive factors. Studies have shown that stainless steel parts treated with electropolishing exhibit stronger corrosion resistance in various environments, which has a significant impact on their durability in a wide range of industrial applications.

Application and Practice of Electropolishing Technology in CNC Machining

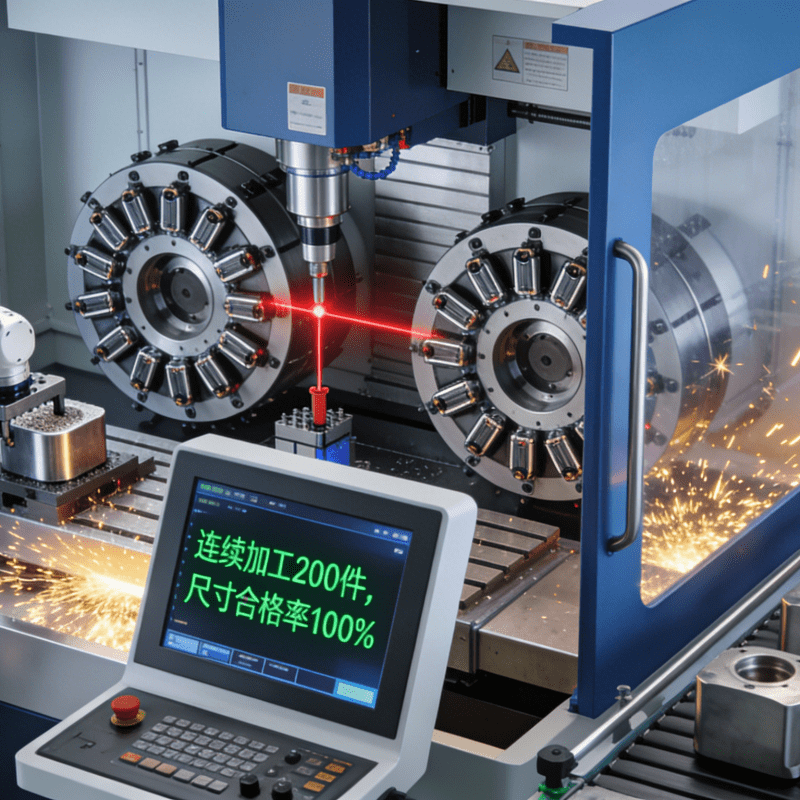

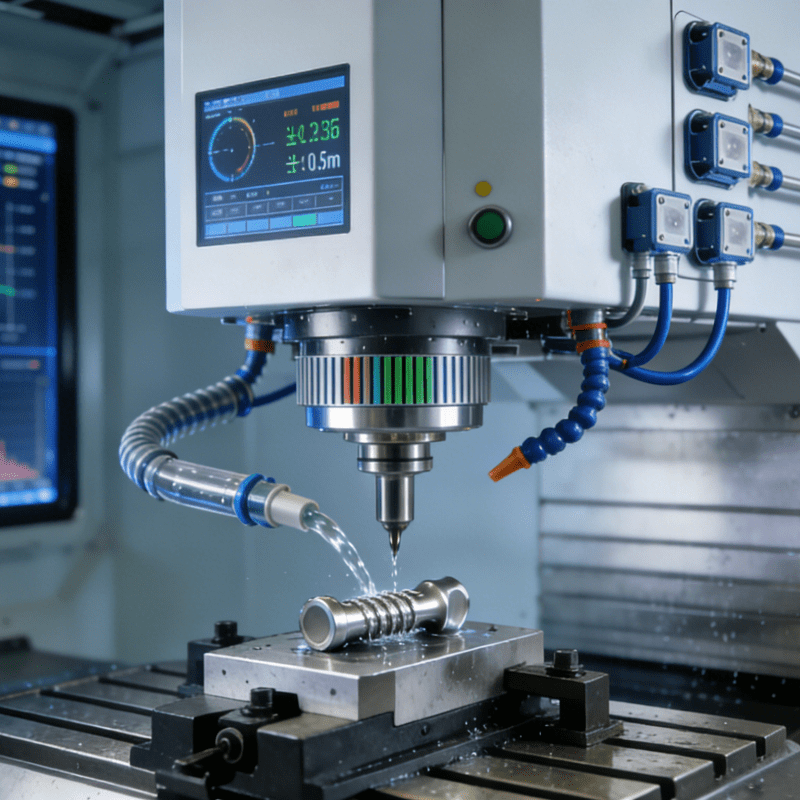

The application of electropolishing technology in CNC machining is becoming increasingly widespread, particularly in the processing of stainless steel parts. By leveraging the chemical action of an electrolyte, this technology smooths out micro-irregularities on the part surface to achieve the desired surface finish. In practical operations, manufacturers first perform CNC machining on stainless steel parts to ensure precise shape and dimensions, then immerse the parts in an electrolyte and achieve polishing through the action of an electric current. This not only enhances the product’s appearance but also significantly improves surface corrosion resistance.

A typical example is the Μηχανή συναρμολόγησης αμορτισέρ (shock absorber assembly equipment) widely used in the automotive industry. Its core components—such as the stainless steel transmission (spindle) that drives part positioning, and the clamping fixtures that fix shock absorber cylinders—need to withstand high-frequency reciprocating motion and occasional contact with workshop coolants or lubricating oils. Without proper surface treatment, micro-burrs on the spindle surface (leftover from CNC machining) would cause increased friction with the guide sleeve, leading to wear-induced precision loss (e.g., positioning deviation exceeding 0.03mm) within 3 months of use; meanwhile, coolant residues would easily accumulate in surface micro-pits, triggering local rust. After electropolishing, the spindle’s surface roughness is reduced from Ra 0.6μm to Ra 0.04μm, cutting friction loss by 35% and extending the component’s service life to over 18 months; the dense oxide film formed also prevents coolant corrosion, ensuring the assembly machine maintains stable precision during mass production of shock absorbers.

Many industries, such as medical devices and food equipment, have extremely high requirements for the surface quality of stainless steel parts, and electropolishing technology precisely meets these needs. In this way, both product quality and service life are improved.

Analysis of Electropolishing Effects on Improving Corrosion Resistance of Stainless Steel Parts

Electropolishing is an effective technology for enhancing the corrosion resistance of stainless steel parts. During the electrolysis process, micro-irregularities on the surface are gradually removed, forming a smooth and glossy surface. This smooth surface reduces the adhesion of dirt and impurities, minimizing sources of corrosion. Meanwhile, the action of electron flow makes the crystal structure inside the metal more uniform, thereby improving corrosion resistance. Studies have shown that the corrosion resistance of stainless steel parts treated with electropolishing can be significantly improved, especially in harsh environments. This process not only enhances the material’s appearance but also provides protection for its long-term use.

Unveiling the Impact of Electropolishing on the Quality of Stainless Steel Products

The improvement of stainless steel part quality by electropolishing is mainly reflected in surface finish and corrosion resistance. After electropolishing treatment, micro-defects on the part surface are effectively repaired, forming a smooth metal surface layer. This smoothness not only enhances the visual effect but also reduces the adhesion of bacteria and dirt, thereby effectively improving hygiene conditions. In addition, electropolishing can remove the oxide layer, making the protective film on the stainless steel surface more uniform and stable, thus enhancing its corrosion resistance. Through this treatment, the durability of the parts under chemical and environmental influences is significantly improved. Overall, electropolishing technology plays a key role in the manufacturing of stainless steel products, providing high-quality, long-life components for the market.

Electropolishing technology brings significant advantages to the surface treatment of stainless steel parts. It is worth noting that through this technology, micro-defects on the part surface can be effectively repaired, which not only improves surface finish but also enhances corrosion resistance. After electropolishing, a uniform thin film is formed to protect the metal surface, enabling it to exhibit stronger corrosion resistance when exposed to the external environment. Furthermore, this technology helps improve the overall aesthetics of the product, making stainless steel products more competitive in the market. Therefore, electropolishing occupies a key position in improving the quality of stainless steel parts and is an indispensable link in modern manufacturing.