The “first year of humanoid robot mass production” is no longer a vision, but an ongoing industrial race. As many enterprises have intensively announced their mass production schedules, humanoid robots are rapidly moving from laboratory blueprints to the broad “battlefield” of applications.

Mass Production Pace Accelerates: From Laboratory Blueprint to Industrial Application

Recently, the pace of mass production in the humanoid robot industry has significantly accelerated. Some enterprises have announced that they will achieve large-scale mass production within the next one to two years, and their products will accurately enter high-value tracks such as industrial manufacturing and home services. Other enterprises have stated that they have reached intentions with multiple partners to jointly promote the rapid implementation and in-depth application of humanoid robots in specific scenarios.

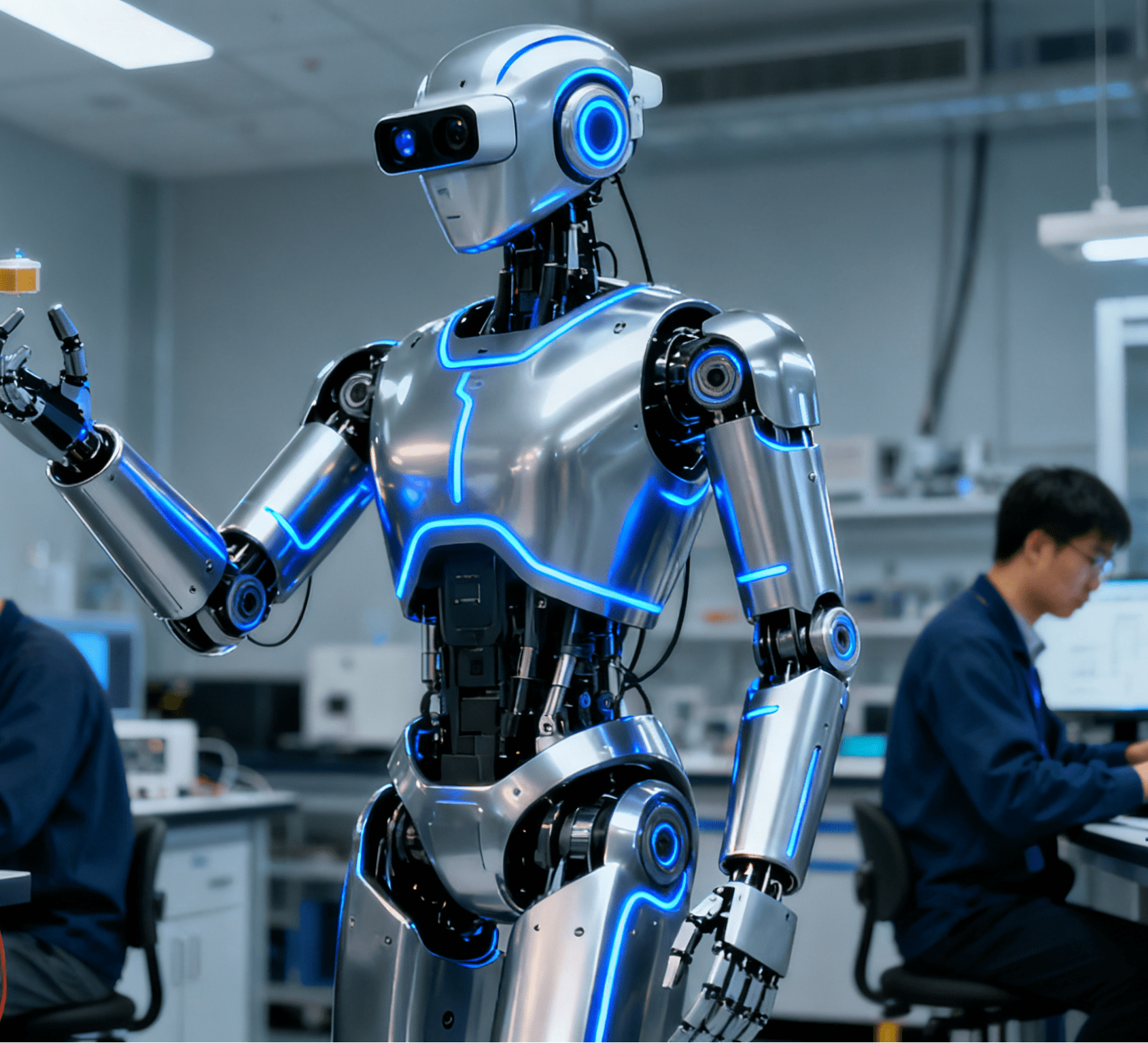

On November 12th, UBtech officially launched the mass production and delivery of the first batch of hundreds of full-size industrial humanoid robots, Walker S2, which will be put into frontline industrial applications in batches. It is reported that Walker S2 stands 168 cm tall, weighs 85 kg, and has 36 degrees of freedom, boasting stronger mobility and environmental adaptability. Equipped with advanced visual recognition and voice interaction systems, it can accurately identify various objects and instructions in industrial scenarios, collaborate with human workers, and improve production efficiency.

To ensure the stability and consistency of key electrical control components in mass-produced robots, UBtech has integrated advanced contactor assembly machines into its production lines—these machines enable high-precision, automated assembly of contactors, critical for the reliable operation of the robot’s power distribution and motion control systems, and strongly support the scaled delivery of Walker S2.

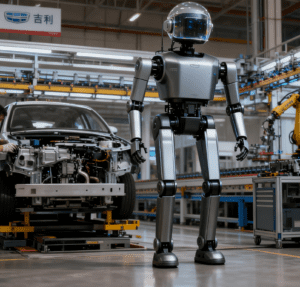

It is learned that UBtech has established cooperation with many industry-leading enterprises such as BYD, Dongfeng Liuqi, Geely Automobile, Foxconn, and SF Express, covering key fields including automobile manufacturing, 3C electronics, and logistics. The mass-produced Walker S2 delivered this time will be mainly used in frontline production links of industries such as automobile manufacturing and 3C electronics to help enterprises achieve intelligent upgrading.

Key Players’ Layout: Diverse Technical Routes & Clear Mass Production Goals

Coincidentally, on November 12th, Changan Automobile officially “revealed” its humanoid robot plan! On the interactive platform, the company stated that it is continuously accelerating its layout and joining hands with partners to explore application scenarios such as industrial robots and store service robots.

At the technical level, Changan Automobile focuses on overcoming core bottlenecks in the robot field and is committed to achieving independent breakthroughs in key technical areas such as the “brain”, “energy”, and “drive”. Based on a clear technical roadmap, Changan Automobile has set a clear goal: to mass-produce and roll off humanoid automotive robots in 2028. This move will not only reshape production and service models but also aim to set a new technical benchmark for the entire high-end manufacturing industry!

On November 6th, XPeng Motors released its new generation of humanoid robot IRON, with the goal of achieving large-scale mass production by the end of 2026.

The humanoid robot IRON features a human-like spine, bionic muscles, and fully covered flexible skin. It stands 178 cm tall, weighs 70 kg, and has 26 degrees of freedom, enabling it to simulate more delicate human movements. Moreover, it is equipped with XPeng’s independently developed Turing AI chip, which possesses strong computing capabilities and intelligent interaction capabilities, allowing it to be widely used in commercial service scenarios such as reception, guided tours, and item delivery. XPeng’s humanoid robot IRON demonstrates the advanced level of current robot technology and will prioritize entering commercial scenarios to provide services after mass production.

Three-Camp Competition & Future Trend: Toward “Hardware + Software + Services” Integration

The market boom has also given rise to a diversified competitive landscape. According to observations from the Intelligent Manufacturing Network, the main players entering this field are currently divided into three major camps:

Professional robot companies represented by UBtech, which seize market opportunities relying on their profound technical accumulation;

Automobile enterprises such as Changan Automobile and XPeng Motors, which rely on their solid foundations in manufacturing, artificial intelligence, and supply chain management to redefine “automotive robots”;

Technology enterprises and start-ups that form alliances. They either build barriers in the AI “brain” or seek differentiated advantages in specific scenario applications.

The “coexistence of multiple strong players” not only promotes the iteration and upgrading of technology but also expands the industrial cake through competition and cooperation!

Looking ahead to the next 1-2 years, the humanoid robot industry will enter a critical verification period, moving from “mass production” to “practical application”. The core of development lies in overcoming the test of the “deep-water zone of scenarios” — that is, how to achieve stability and efficiency in real scenarios while controlling costs.

In terms of competition, the focus will shift from hardware competition to the integrated capability of “hardware + software + services”. Whoever can enable robots to understand instructions faster, adapt to changes, and solve problems independently will gain an advantage!