A Colossal Component: The Tokamak Module’s Design and Origins

The module in question is one of nine critical “building blocks” that, once assembled and welded, will form the tokamak’s doughnut-shaped vacuum vessel—a marvel of engineering. Standing as tall as a five-story building and weighing as much as four fully loaded jumbo jets, it is a complex assembly of groundbreaking components sourced from three ITER Members: Korea supplied the vacuum vessel sector at its core and the thermal insulation panels; Europe and Japan contributed the pair of toroidal field coils that complete the structure.

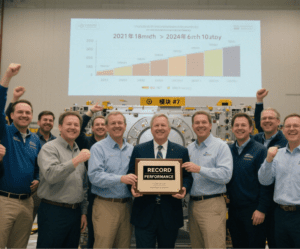

From Struggle to Success: A Tripling in Assembly Efficiency

Assembling such a module—integrating these three major components alongside countless pipes, connectors, and accessories—is no small feat. When assembling Sector Module #6 in 2021–2022, the process took 18 months. (Installed in the tokamak pit in May 2022, it was later extracted 14 months later for repairs.) Yet the lessons learned from that arduous effort proved transformative: the team behind Sector Module #7 slashed assembly time by two-thirds, completing it in just six months and ten days. This milestone was celebrated on Friday, 28 March, with the team vowing to “do even better next time.”

The Power of Expertise: Adaptive Execution

The expertise gained from earlier lifting, transfer, and installation operations proved invaluable during last week’s work. “The foundation of this success lies in clear engineering definitions—tasks properly documented and fully understood by the team,” explains Daniel Coelho, the ITER assembly engineer who coordinated both the 2022 operation and last week’s effort. “While most team members focus on following protocols, we need a few with deep insight into why those protocols exist—people who can assess deviations, adapt confidently, and keep the process on track.” To reinforce this, “veterans” from the 2022 and 2023 Sector Module #6 operations, now working elsewhere on the project, were temporarily reassigned to support last week’s task—ensuring hard-won knowledge was put to use.

A Broader Trend: Automation and Precision in Advanced Manufacturing

This leap in efficiency mirrors broader trends in advanced manufacturing, where automation and precision drive progress. The surge in productivity aligns with the growing focus on high-quality production, sustainability, and the adoption of cutting-edge technologies in manufacturing. As industries worldwide embrace automation, the reliability and efficiency of systems like universal automatic assembly machines have become paramount—enabling faster turnaround, customization, and reduced waste.

The Evolving Market: Growth of Automated Systems

These machines, designed to boost productivity, cut labor costs, and enhance precision across industries, are reshaping manufacturing landscapes. Fueled by the relentless pursuit of efficiency, their market is evolving rapidly, with demand surging as businesses invest in state-of-the-art automation. Integration of AI and machine learning further elevates their capabilities, optimizing operations, minimizing downtime, and boosting overall productivity. By 2032, the market for such systems is projected to exceed several billion dollars—a testament to their role as cornerstones of future manufacturing.

A Hard-Earned Victory:Final Milestone

Back at the tokamak site, with the module lowered to the pit’s bottom and past its final major technical hurdle, the team pressed on. Granted a special extension by ITER management, they worked through the night, and by 1:30 a.m., the mission was accomplished: the module rested safely in its temporary position. A small but significant victory—one that underscores how expertise, adaptability, and advancing automation are turning even the most daunting engineering challenges into achievable milestones.

Automated assembly machine: Purchasing guide

Artificial intelligence automated assembly robot