In the competitive cosmetics industry, lip gloss manufacturers face persistent pain points: low manual assembly efficiency, rising labor costs, inconsistent product quality and slow response to diverse market demands. For brands aiming to scale production and optimize operations, upgrading to professional automation equipment is no longer an option but a necessity. Ruizhi Intelligent Manufacturing’s All-in-One Lip Gloss Assembly Machine is engineered to address these core challenges, delivering tailored, efficient and reliable solutions for cosmetic production lines of all scales. Below are the key reasons to integrate this non-standard automation equipment into your lip gloss manufacturing process.

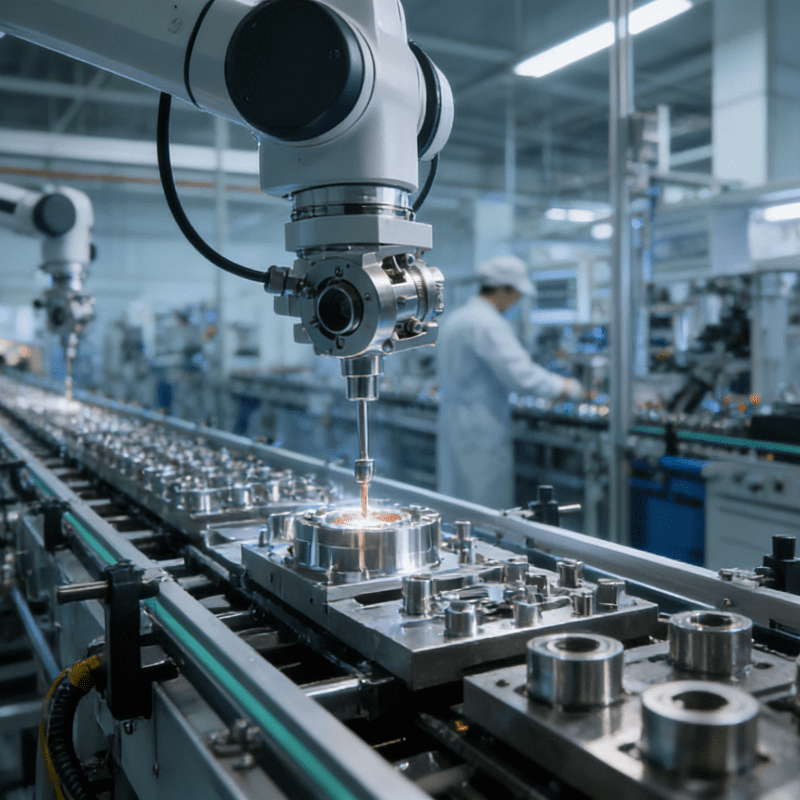

Slash Operational Costs While Boosting Production Efficiency

Traditional lip gloss assembly relies on manual labor for filling, capping, and sorting, with a small team of workers achieving just 200-300 pieces per hour—slow and costly for mass production. Our all-in-one machine integrates all core production processes in a single unit, with an output of 2500-2800 pieces per hour, an 8-10x increase in efficiency compared to manual work. It only requires one operator for supervision and maintenance, cutting labor costs by over 80% and supporting 24/7 continuous operation. This efficiency leap directly translates to higher production volume, faster order fulfillment and maximized profit margins for your cosmetic line.

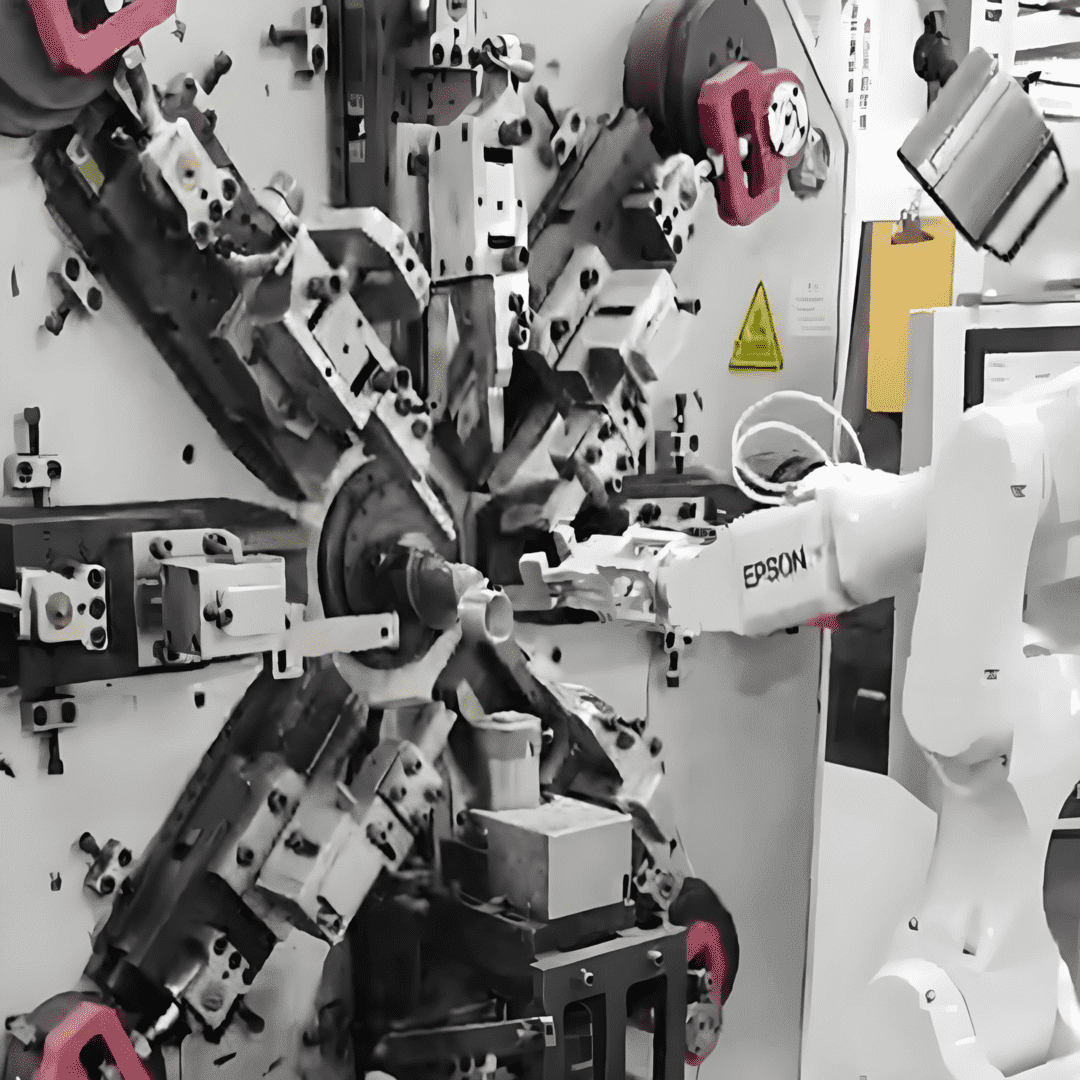

Ensure Uncompromising Product Quality with Precision Automation

Inconsistent filling levels, loose caps and misaligned packaging are common issues with manual assembly, leading to high product return rates and brand reputation damage. Our lip gloss assembly machine is equipped with a PLC control system, AI visual positioning and closed-loop torque control, ensuring assembly precision within ±0.05mm. A built-in real-time quality inspection module automatically detects and sorts unqualified products, pushing the pass rate to 99.8%. Stable, repeatable precision guarantees uniform product quality across every batch, a critical factor for building customer trust in your cosmetic brand.

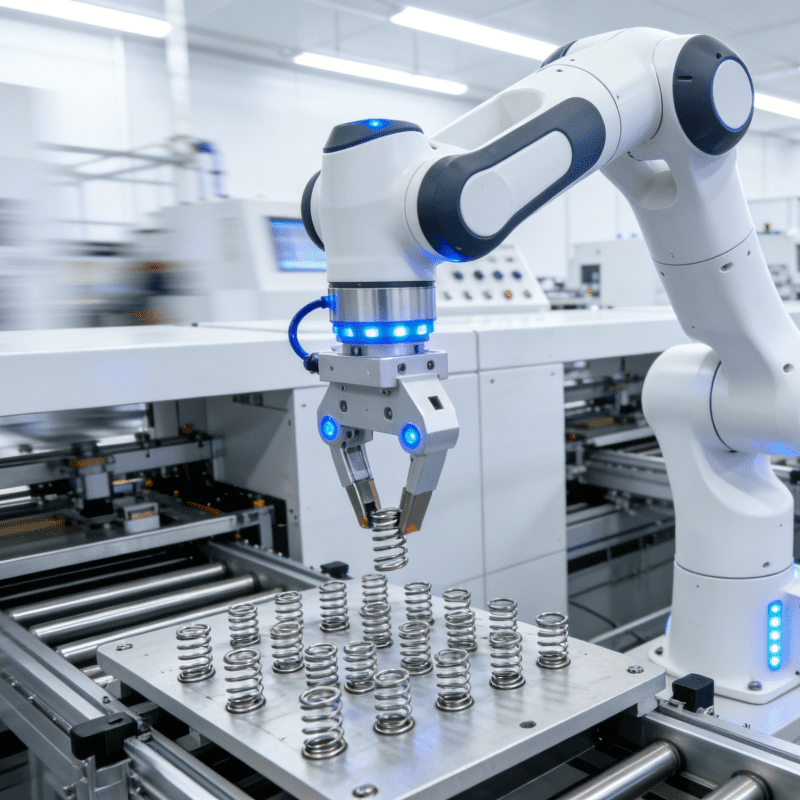

Flexible Customization for Diverse Cosmetic Production Needs

Lip gloss products come in endless variations—different tube diameters, cap styles, and filling volumes—posing a challenge for rigid, one-size-fits-all automation equipment. As a leader in non-standard automation, Ruizhi Intelligent Manufacturing designs our all-in-one machine for full flexibility. The equipment can be quickly adjusted to adapt to various lip gloss formats, with a parameter memory function that shortens product changeover time to just 5 minutes. We also offer one-stop customized solutions, from demand analysis and prototype testing to on-site commissioning and after-sales support, paired with a 2-year machine warranty and 48-hour online technical service. Every detail is tailored to match your unique production line requirements.

For cosmetic brands looking to stay ahead in the market, investing in Ruizhi Intelligent Manufacturing’s All-in-One Lip Gloss Assembly Machine is a strategic move to streamline production, elevate quality and build a more agile, cost-effective manufacturing system. It’s not just a piece of equipment, but a long-term partner for your cosmetic line’s growth.