In the treatment of respiratory diseases such as asthma, chronic obstructive pulmonary disease (COPD), and pediatric bronchitis, medical nebulizers are a “life-saving tool” that converts liquid medicine into fine aerosol particles for direct inhalation into the lungs. With the aging population, the spread of respiratory infectious diseases, and the growing demand for home medical care, the global medical nebulizer market has maintained a compound annual growth rate of over 8% in recent years. However, unlike ordinary consumer products, medical nebulizers consist of dozens of precision components—from the micron-level mesh atomizing sheet and leak-proof liquid medicine cup to the flexible air and one-way valve—each part’s assembly accuracy and cleanliness directly determine the device’s efficacy and safety.

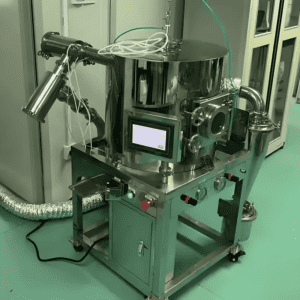

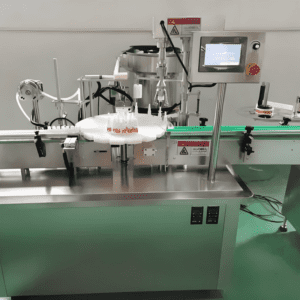

Against this backdrop, the Nebulizer Assembly Machine (NAM) has emerged as a core production equipment in the medical device industry. It replaces manual assembly with automated, precision-controlled processes, solving the pain points of traditional manual operations and becoming a key driver for the large-scale, high-quality production of medical nebulizers.

The “Unsolvable Dilemma” of Manual Assembly: Why Medical Nebulizers Need Specialized Assembly Machines

Medical nebulizers have extremely strict requirements for assembly—far exceeding those of ordinary mechanical products—due to their direct contact with human respiratory systems. Manual assembly, however, faces insurmountable bottlenecks in four core areas:

- Micron-level Precision Requirements: Manual Operation “Cannot Reach”

The core component of a nebulizer, the atomizing sheet (especially mesh atomizing sheets), has a pore size of only 3-5 μm (equivalent to 1/20 the diameter of a human hair). During assembly, the atomizing sheet must be aligned with the liquid medicine cup’s outlet with an error of less than ±0.01 mm; otherwise, it will cause uneven atomization (particle size exceeding the therapeutic range of 1-5 μm) or even liquid leakage. Manual assembly relies on workers’ visual judgment and hand-eye coordination, which can only achieve an accuracy of ±0.1 mm at best—far from meeting medical standards.

- Strict Cleanliness Standards: Manual Operation “Cannot Avoid Contamination”

Medical nebulizers are classified as Class II medical devices in most countries, requiring assembly environments to meet ISO 8 (Class 100,000) or higher cleanliness levels. Manual assembly involves direct contact between workers’ hands, gloves, or tools with components, easily introducing dust, oil stains, or microorganisms. Even in a cleanroom, the risk of contamination from manual operations remains 5-8 times higher than that of automated assembly—once contaminated, the nebulizer may cause respiratory infections in patients.

- Consistency Requirements for Mass Production: Manual Operation “Cannot Stabilize”

A medium-sized medical device factory needs to produce 5,000-10,000 nebulizers per day. Manual assembly is affected by workers’ fatigue, skill levels, and emotional states: for example, the torque used to fasten the liquid medicine cup’s lid may vary from 0.8 N·m to 1.5 N·m (the standard range is 1.0±0.1 N·m). This inconsistency leads to a pass rate of only 85-90% for manually assembled nebulizers, while defective products (such as loose lids or damaged valves) not only waste materials but also pose safety risks if they flow into the market.

- Efficiency Bottlenecks: Manual Operation “Cannot Keep Up”

A skilled worker can assemble only 30-50 nebulizers per hour, and needs 2-3 breaks a day to avoid fatigue. For factories with an annual output of 2 million nebulizers, manual assembly requires a team of 50-80 workers, resulting in high labor costs (accounting for 30-40% of total production costs) and difficulty in scaling production. In contrast, a single automated assembly line can achieve an output of 300-500 units per hour, with 24/7 continuous operation.

The “Four-Core Engine” of Nebulizer Assembly Machines: How to Achieve “Precision + Cleanliness + Efficiency”

A high-quality Nebulizer Assembly Machine is not a simple combination of mechanical arms and conveyors, but an integrated system that integrates precision mechanics, visual positioning, force control technology, and clean design. Its core competitiveness lies in four key modules:

- Precision Feeding System: “Orderly Supply” of Tiny Components

Nebulizer parts vary in shape and size—from the cylindrical liquid medicine cup (diameter 30 mm) to the tiny one-way valve (weight only 0.5 g) and the flexible silicone tube. The assembly machine’s feeding system uses a combination of “vibratory bowl + visual positioning + vacuum suction” to ensure accurate delivery of each part:

Vibratory bowls with customized tracks: For small parts like valves and gaskets, the vibratory bowl’s track is designed according to the part’s shape, ensuring parts are arranged in a unified orientation (e.g., valve openings facing upward) without jamming.

3D vision positioning: A high-resolution industrial camera (20 million pixels) captures the position of parts on the conveyor belt, correcting for any offset (up to ±0.5 mm) in real time and guiding the mechanical arm to pick up parts accurately.

Vacuum suction nozzles with soft materials: For fragile parts like mesh atomizing sheets, the suction nozzle is made of medical-grade silicone, which can firmly grasp the part without leaving scratches or marks.

- Multi-Axis Precision Assembly Module: “Gentle and Accurate” Assembly Like a “Micro-Surgeon”

The assembly module is the “core hand” of the NAM, usually composed of 4-6 axis collaborative robots with micron-level motion accuracy:

High-precision motion control: The robot’s repeat positioning accuracy reaches ±0.005 mm, ensuring that the atomizing sheet is aligned with the liquid medicine cup’s outlet with no error.

Force control feedback: A force sensor (accuracy ±0.1 N) is installed at the end of the robot arm. When assembling the atomizing sheet or tightening screws, the sensor monitors the pressure in real time—if the force exceeds the set threshold (e.g., 0.5 N for the atomizing sheet), the robot pauses immediately to avoid damaging the part.

Sequential assembly logic: The machine follows a strict assembly sequence (e.g., “install one-way valve → attach air → fix atomizing sheet → seal liquid medicine cup”) preset by medical device standards, avoiding assembly errors caused by process confusion.

- Online Detection System: “Zero Defect” Quality Gate for Every Nebulizer

Medical products allow no room for error, so the NAM is equipped with a multi-link online detection system to eliminate defective products in real time:

Visual inspection: After each assembly step, a camera checks the part’s position (e.g., whether the atomizing sheet is tilted), appearance (e.g., no scratches on the liquid medicine cup), and size (e.g., the diameter of the air interface).

Sealing performance test: The assembled nebulizer is connected to a pressure sensor, which injects 50 kPa of air into the liquid medicine cup and detects pressure changes within 30 seconds. If the pressure drop exceeds 2 kPa, the product is judged to be leaky and automatically rejected.

Atomization performance sampling inspection: For every 100 products, 1 is randomly selected to test the atomization particle size (using a laser particle size analyzer) and drug residue (using a high-performance liquid chromatograph) to ensure compliance with pharmacopoeia standards.

- Clean Integrated Design: Meeting Medical-Grade Production Requirements

The NAM’s entire body is designed to be compatible with cleanroom environments:

Material selection: The machine’s frame and conveyor belt are made of 316L stainless steel, which is corrosion-resistant, easy to clean, and meets FDA food contact standards.

Sealing and dust prevention: All moving parts (such as robot arms and bearings) are equipped with dust-proof covers, and the electrical control cabinet uses a positive pressure ventilation system to prevent dust from entering.

Easy cleaning and disinfection: The machine’s surface is smooth with no dead corners, and can be disinfected with 75% ethanol or hydrogen peroxide without damaging components—critical for preventing cross-contamination during batch production.

Scene Landing: From “Mass Production” to “Flexible Customization”

Different types of nebulizers (compression-type, ultrasonic-type, mesh-type) and different market requirements (e.g., pediatric nebulizers with small volumes, portable nebulizers for home use) require the NAM to have strong adaptability. Leading manufacturers have developed two types of assembly machines to meet diverse needs:

- High-Speed Production Lines for Large Pharmaceutical Companies

For large enterprises with an annual output of over 5 million nebulizers (such as Philips Respironics and domestic leading medical device companies), the NAM is designed as a linear assembly line with 8-12 stations, each responsible for one assembly step. The line’s output can reach 500 units per hour, and it is connected to the factory’s MES (Manufacturing Execution System) to realize real-time data tracking (e.g., assembly time of each product, detection results, operator information)—facilitating compliance with GMP (Good Manufacturing Practice) requirements.

A case in point: A domestic medical device company in Jiangsu replaced 60 manual workers with 3 NAM assembly lines in 2023. The nebulizer pass rate increased from 88% to 99.5%, production efficiency doubled, and annual labor costs were reduced by 4.2 million yuan. More importantly, the company successfully passed the FDA inspection and entered the U.S. market—thanks to the assembly machine’s traceable data and consistent quality.

- Flexible Assembly Machines for Small and Medium-Sized Manufacturers

Smaller manufacturers often produce multiple types of nebulizers (e.g., switching between adult and pediatric models) and require frequent product changes. The flexible NAM uses a “modular design”: the feeding system, assembly module, and detection module can be quickly replaced (within 30 minutes) by changing fixtures and adjusting program parameters. For example, when switching from a compression-type nebulizer to a mesh-type one, workers only need to replace the vibratory bowl’s track and update the robot’s assembly path in the control system—no need to rebuild the entire production line.

Future Trends: Toward “Smarter, Greener, and More Compliant”

As medical technology advances and global regulatory requirements for medical devices become stricter, Nebulizer Assembly Machines are evolving in three key directions:

- AI-Driven Intelligent Upgrade

Future NAMs will integrate AI vision systems that can automatically identify component defects (e.g., micro-cracks on the atomizing sheet) that are invisible to the human eye, and predict maintenance needs (e.g., alerting when the robot arm’s precision decreases) based on historical operation data—reducing unplanned downtime by 30% or more.

- Green and Energy-Saving Design

With the global focus on carbon neutrality, NAMs will adopt energy-saving components (e.g., servo motors with 95% energy efficiency) and recyclable materials. Some manufacturers are even developing “low-energy assembly processes” that reduce power consumption by 20% compared to traditional machines.

- Global Regulatory Compliance

As nebulizers are exported to more countries and regions, NAMs will be preconfigured to meet different regulatory standards—for example, automatically adjusting assembly parameters to comply with the EU’s CE certification (stricter on material safety) or Japan’s PMDA requirements (stricter on cleanliness). The machine’s data system will also support multi-language report generation (English, Japanese, German) to simplify the certification process for export enterprises.

Conclusion: More Than an Assembly Tool—A “Guardian” of Medical Device Quality

The Nebulizer Assembly Machine is not just a piece of production equipment; it is a critical link in ensuring the safety and efficacy of medical nebulizers. In an era where “every micron matters” for medical devices, it solves the contradictions between manual assembly’s limitations and medical product requirements, and empowers the medical device industry to achieve large-scale, high-quality production.

As China’s medical device industry accelerates its pace of localization and globalization, the development of high-performance Nebulizer Assembly Machines will not only reduce reliance on imported equipment but also help domestic nebulizer brands meet global quality standards—ultimately benefiting patients worldwide by providing safer, more effective respiratory treatment tools.