Table of Contents

ToggleRobots Automate the Assembly of Airbag Sensors

Robots Automate the Assembly of Airbag Sensors

Automated quality inspection equipment for sanitary ware assembly, shower head assembly equipment, bathroom fixture assembly equipment, toilet assembly production lines, etc. In the automotive field, there are contactor assembly machines, fuse assembly machines, etc.In the complex web of automotive safety features, automotive airbags stand out as a revolutionary and life – saving innovation. Since their introduction, they have become an integral part of vehicle safety systems, and their impact on reducing fatalities in car accidents has been nothing short of remarkable. When paired with seat belts, which are another cornerstone of automotive safety, airbags have transformed the odds of survival in the event of a collision. Their effectiveness is not just a matter of speculation but is backed by extensive real – world data and research.

The National Highway Traffic Safety Administration’s assessment reveals a staggering statistic. Between 1987 and 2016 in the United States alone, frontal airbags have been responsible for saving more than 50,000 lives. In frontal collisions, these airbags have proven to be highly effective in reducing the mortality rate. They have decreased the death rate of drivers by 29% and that of front – seat passengers aged 13 and above by 32%. When airbags are used in conjunction with seat belts, the risk of death in frontal collisions plummets by a substantial 61%. Side airbags, particularly those designed to safeguard the head, add an extra layer of protection, further reducing the risk of death when a collision occurs on the driver’s side.

Therefore, it is not surprising that the demand for this technology is constantly increasing. The consulting firm Fortune Business Insights estimates that the global market value of automotive airbags was $16.3 billion in 2024. In addition, it is expected that in the next seven years, this market will grow at a rate of 7.2% per year, increasing from $17.1 billion in 2025 to $27.74 billion in 2032.

ZF Friedrichshafen AG is one of the world’s largest automotive parts suppliers and holds an important position in the airbag market. The company manufactures frontal, side, and knee airbag systems. This year, it launched a new airbag to protect the lower legs.

ZF not only produces airbags but also manufactures the sensors that trigger the deployment of airbags. During a collision, these sensors provide key information to a dedicated electronic control unit (ECU), including the type of collision, the angle of collision, and the severity of the impact. The ECU uses this data to determine whether the collision meets the criteria for airbag deployment and triggers various ignition circuits to deploy one or more airbag modules inside the vehicle.

ZF produces these sensors and ECUs at its assembly plant in Peterlee, UK. Until recently, the production of airbag modules at this plant relied heavily on manual labor. The continuous growth of demand and the desire to bring more supply chain links in – house have made it necessary for the plant to make new investments in a dedicated assembly line.

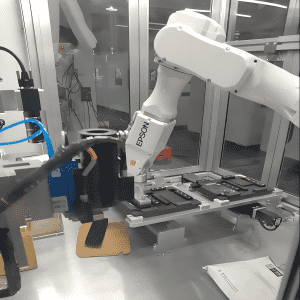

SCARA Robot

This SCARA robot has a working radius of 620 millimeters and a maximum load capacity of 8.4 kilograms.

Robots Realize Automated Assembly

To design and build this production line, ZF brought in the German system integrators Grohmann Engineering and IPTE Factory Automation. Preliminary analysis showed that simply expanding or replicating the existing manual assembly line could not compete with a fully automated production line in terms of either output or cost – effectiveness. Therefore, ZF chose a brand – new fully automated assembly line that uses four – axis and six – axis robots provided by Stäubli Robotics.

The new assembly line consists of multiple work cells connected in series, all of which are equipped with Stäubli robots. In the first step of operation, two Stäubli TS60 SCARA robots insert a metal contact into a printed circuit board. The next step is to solder the electrical contacts on the circuit board. In the subsequent quality inspection process, another TS60 SCARA robot will operate on the components.

The next stage is the overmolding of the printed circuit board. This process is completed by two six – axis RX160 robots, which were selected because of their working range and dynamic performance.

After overmolding, the robots transfer the module to the final quality assurance inspection station, where the module will be tested to ensure that it can be triggered correctly in case of an accident. To pass the test, the response time of the airbag signal must not exceed 19 milliseconds.

Six – axis Robot

ZF uses Stäubli robots in its assembly plant network around the world. This six – axis robot assembles airbags in a factory in Germany.

The new assembly line has significantly reduced the defective rate in these tests, and currently, the defective rate has dropped to below 0.1% —— a remarkable improvement compared to the previous manual assembly system that used a large number of outsourced components.

At the last station of the production line, the products will be marked and labeled to ensure 100% traceability of the products.

The engineers and assembly workers of ZF quickly mastered the management of the new production line. This production line achieved uninterrupted operation for 24 hours a day, six days a week within the first seven months of its operation.

Due to the flexibility of this production line, different models of airbag modules can be produced. Shortly after the production line was put into operation, ZF had already started producing 12 different models of products. Compared with the manual assembly system, this automated production line has reduced the number of workers by 12.

The implementation of the new automated production line at ZF’s Peterlee plant represents a significant leap forward in automotive airbag manufacturing. By embracing advanced robotic technology, ZF has not only met the growing market demand more efficiently but has also set new standards for quality and productivity within the industry. The remarkable reduction in the defective rate, the ability to produce a diverse range of airbag module models, and the substantial decrease in the workforce required are all testaments to the success of this investment.

As the global automotive airbag market continues its projected growth over the next seven years, ZF is well – positioned to capitalize on this expansion. The company’s ability to quickly adapt to the new production line and achieve continuous operation showcases its resilience and forward – thinking approach. Moreover, the enhanced traceability of products through the marking and labeling process at the end of the line ensures that safety and quality control remain at the forefront.

Looking ahead, ZF’s adoption of automated assembly lines could serve as a model for other automotive parts manufacturers. It demonstrates the potential for technological innovation to revolutionize production processes, improve product quality, and ultimately contribute to enhancing automotive safety on a global scale. The future of automotive airbag manufacturing, with ZF leading the way, appears to be one of greater efficiency, reliability, and innovation.