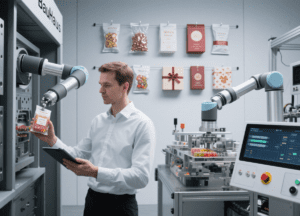

In the wave of large-scale development of the candy industry, fully automatic packaging equipment has become an indispensable core of the production line. This automated system, integrating multidisciplinary technologies such as mechanical engineering, electrical control, and pneumatic transmission, is redefining the production standards of candy packaging with its efficient, precise, and stable performance. Technical […]

Technical Architecture: Precise Operation of Multi-System Collaboration

The excellent performance of such equipment stems from its complex and sophisticated technical architecture. The feeding system adopts a combination of a vibrating plate and a servo motor, and precisely controls the candy conveying speed through a Programmable Logic Controller (PLC) to ensure that single or grouped candies enter the packaging station at preset intervals, with an error controlled within ±0.5mm. The packaging film supply system is equipped with an automatic tension compensation device, which can adjust the pulling force in real-time according to the ductility of different materials (such as BOPP, PVC, aluminum-plastic composite film) to avoid wrinkling or breaking of the film.

The sealing mechanism is a key component reflecting the precision of the equipment. It adopts high-frequency induction heating or pulse heat sealing technology, which can raise the temperature from room temperature to 180°C within 0.3 seconds. Cooperating with a silicone pressure roller, it achieves a sealing edge with a width of 3-5mm, and the sealing strength can reach 0.8N/15mm, fully meeting the sealing requirements of food packaging. The transmission system, through the combination of a synchronous belt and a cam divider, controls the mechanical operation error within 0.1°, ensuring the precise timing coordination of each process.

Workflow: Seamless Connection from Raw Materials to Finished Products

After the equipment is started, it undergoes a series of continuous and efficient operating procedures. Candies enter the buffer silo through a hoist, and the material level is detected by a photoelectric sensor to automatically start and stop feeding; then they slide into the material sorting plate through an inclined conveying trough, and complete directional arrangement under the action of centrifugal force. Unqualified irregular candies will be automatically rejected by the air blowing device.

When the candies reach the packaging station, the packaging film is folded into a cylindrical shape by a forming machine and conveyed to the wrapping position through a traction roller. At this time, the transverse sealing knife closes instantly to complete the sealing of the first end and cut off the previous section of packaging. As the conveyor belt steps forward, the candies are wrapped into the film cylinder, and the longitudinal heat-sealing wheel continuously rolls to complete the side sealing. Finally, it is cut off by the transverse sealing knife at the end to form an independent packaging unit. The entire process is fully automated, and each device can complete the packaging of 300-800 candies per minute, equivalent to the workload of 20 manual workers.

Core Advantages: Industrial Upgrade Brought by Automation

Compared with traditional manual packaging, fully automatic equipment shows advantages in multiple dimensions. In terms of efficiency, continuously operating equipment can achieve more than 20 hours of effective production per day, with a single-shift output increased by more than 300%; in terms of precision, the combination of a weight detection device and a visual recognition system can automatically identify defects such as packaging deviation and missing candies, with a rejection rate of 99.9%, significantly reducing quality risks.

The savings in labor costs are even more considerable. For a candy production line with an annual output of 1,000 tons, the number of packaging workers can be reduced by 80% after adopting fully automatic packaging. The flexible design of the equipment is also worthy of attention. By replacing molds and adjusting parameters, the packaging can be switched from hard candies to soft candies, and from round to irregular shapes within 30 minutes, meeting the production needs of small batches and multiple varieties.

Future Trend: Integration of Intelligence and Greenization

With the penetration of Industry 4.0 technology, the new generation of packaging equipment is developing towards intelligent adaptation. Equipment equipped with machine vision can automatically identify changes in candy color and shape and adjust packaging parameters; IoT modules can upload equipment operation data in real-time, and perform fault early warning and production capacity analysis through cloud platforms. Under the trend of environmental protection, the application of cold sealing technology with solvent-free adhesives and the adaptive transformation of degradable films will enable the equipment to achieve low-carbon production while maintaining high efficiency.

From bulk candies on street corners to exquisite gift sets, such automated equipment not only improves production efficiency but also shapes brand images through standardized packaging quality. This system, which perfectly integrates mechanical precision and digital intelligence, is becoming a key fulcrum for the candy industry to move from traditional manufacturing to intelligent manufacturing, continuously injecting technological momentum into the sweet economy.

What is the difference between a case packer and a packaging machine?