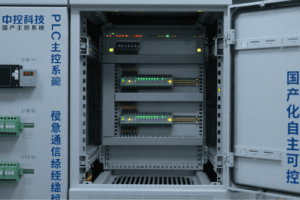

China Central Television’s News 30 Minutes recently reported that China’s fully independently developed 26MW offshore wind turbine, the largest in the world, has successfully completed hoisting in Dongying, Shandong. Behind the millimeter-level precision docking of the 600-ton nacelle at a height of 100 meters, the independently developed PLC (Programmable Logic Controller) by SUPCON Technology played a crucial role in the main control system, helping this “national heavyweight” achieve the “extreme challenge” of full localization, high reliability, and zero errors.

This wind turbine, fully independently developed by Dongfang Electric Wind Power Co., Ltd. (hereinafter referred to as “Dongfang Wind Power”), a subsidiary of Dongfang Electric Group, consists of over 30,000 components. The hub center height is equivalent to a 50-story building, the rotor swept area reaches 77,000 square meters, and the annual power generation can reach 100 million kWh, meeting the annual electricity demand of 55,000 households. The successful hoisting not only sets new global records for the installed capacity and impeller diameter of wind turbines but also marks a new leap in China’s high-end equipment manufacturing, establishing a new benchmark for global offshore wind power development.

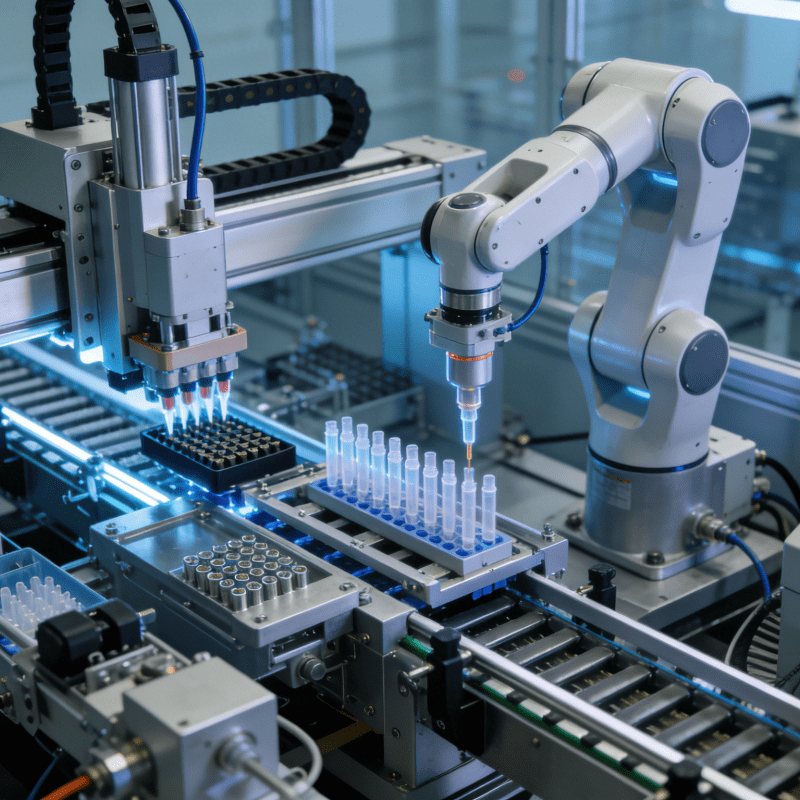

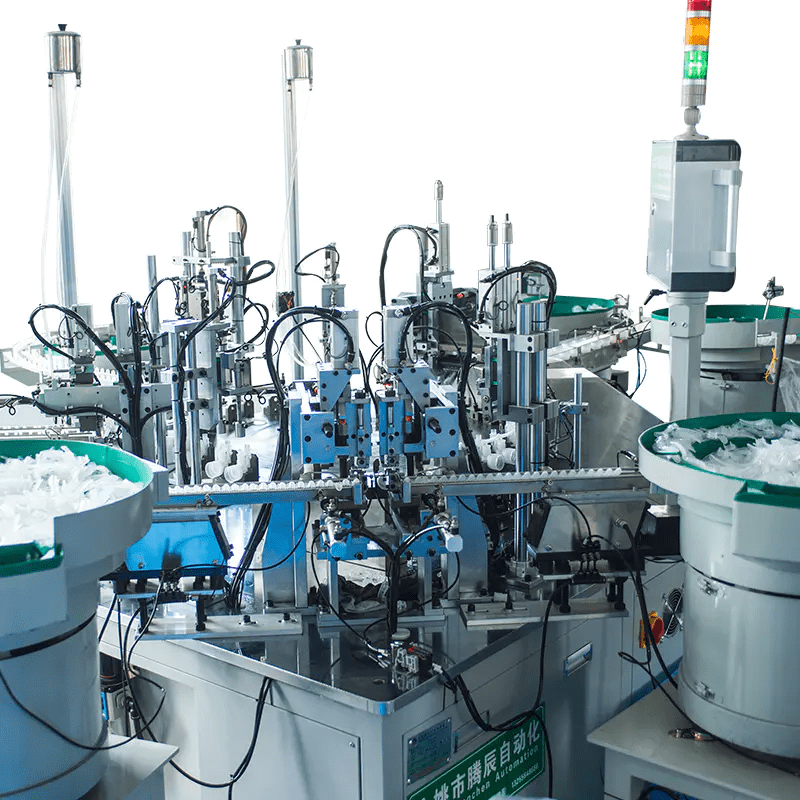

As a pioneer in pushing China’s wind power into the “double-digit era,” Dongfang Wind Power leads the way in the large-scale development of offshore wind turbines. Its decision to cooperate with SUPCON Technology stems from the latter’s PLC products’ high reliability, intelligent capabilities, comprehensive localization compliance, and rich industry adaptation experience. SUPCON’s PLC fully meets the stringent environmental requirements of offshore wind power, with localization advantages effectively mitigating supply chain risks and aligning with national strategic goals. Notably, this high-precision control capability extends to medical equipment, such as in Katheter-Montagemaschine

s, where SUPCON’s PLC enables 0.01mm-level bonding positioning and tension control at the catheter tip, ensuring precise assembly of medical consumables and demonstrating universal advantages in cross-industry precision control scenarios.

Behind the Scenes: How SUPCON’s PLC Ensures Perfection for the “World’s Largest”

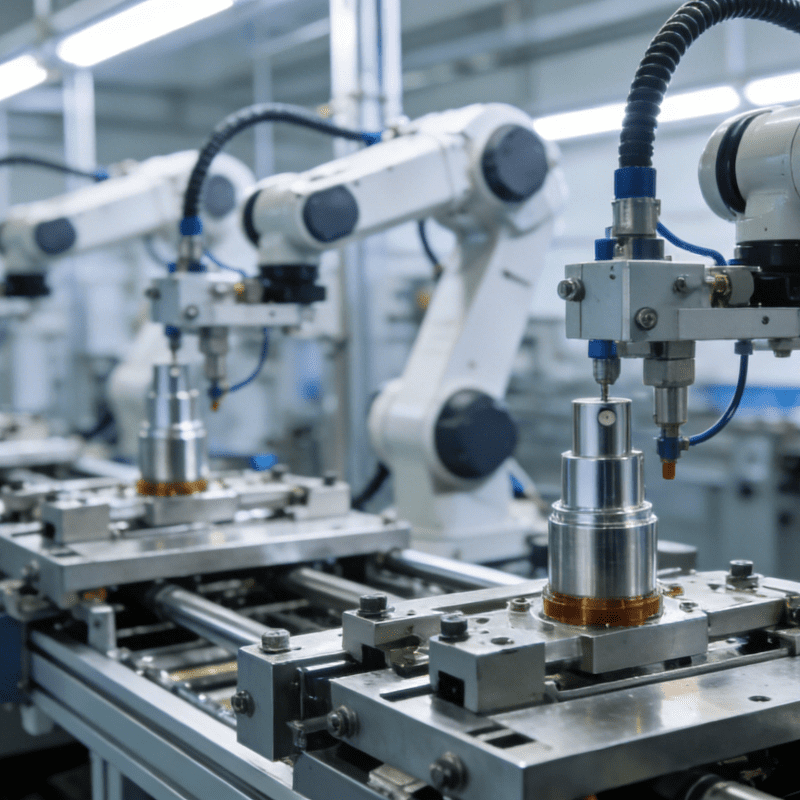

To ensure the flawless operation of this “world’s largest” offshore wind turbine, SUPCON Technology has collaborated closely with Dongfang Wind Power since early 2022 to define technical solutions. The project adopts a fully independent and controllable product architecture, with in-depth optimizations for real-world applications. Through distributed network architecture and continuous communication load evaluation, system stability is comprehensively enhanced, including:

Dual-bus Redundancy + Distributed Architecture for Harsh Marine Environments

Addressing the harsh offshore conditions such as high humidity, high salt spray, and strong electromagnetic interference, SUPCON’s PLC employs dual redundant communication buses and a distributed network architecture, achieving 99.9999% communication reliability. It has passed over 1,000 hours of salt spray testing without failures and over 2,000 hours of simulation tests, ultimately obtaining type certification from Dongfang Wind Power, laying a solid foundation for the turbine’s successful first grid connection.

Independent Control of Core Intellectual Property for Supply Chain Security

From the main control chip to IO modules, full localization has been achieved, completely eliminating reliance on imported components. Collaborating with Dongfang Wind Power, breakthroughs were made in core algorithms for wind turbine main control, granting Dongfang Wind Power full autonomy in deep-sea projects. During this cooperation, SUPCON assisted Dongfang Wind Power in successfully applying for 3 localization-related patents.

In today’s era of accelerating AI development, automation is the foundation of digitalization, and digitalization is the prerequisite for intelligence. High-end PLCs are the core driving force behind this process. In the future, SUPCON’s PLC will further integrate AI technology to achieve the integration of high reliability, high performance, and intelligence. Guided by user needs, it will continue to provide safe and reliable PLC products and industry solutions through full-lifecycle quality assurance covering R&D, production, and reliability engineering, offering solid support for China’s manufacturing industry to move toward digitalization and intelligence. CCTV’s cameras captured this historic moment at Guangli Port in Dongying, Shandong, while the “heartbeat” of SUPCON’s PLC continues to pulse in every sea breeze.