Table of Contents

ToggleRevolutionizing Flexible Vibratory Feeding: Ruizhi Intelligence Leads the New Paradigm of Intelligent Feeding Technology

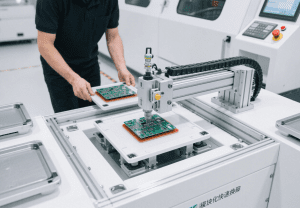

Against the backdrop of global manufacturing’s transition to multi-variety and small-batch production, traditional vibratory bowl feeding models have struggled to meet the demands of precision manufacturing due to low changeover efficiency and high part damage rates. Recently, Ruizhi Intelligence has introduced the new-generation Flexible Vibratory Feeder, which overcomes flexible feeding challenges in fields such as 3C electronics, medical devices, and automotive precision parts through AI visual sorting and multimodal vibration control technologies, propelling automated production lines into a new stage of intelligent feeding featuring “zero damage and second-level changeover”.

Core Technological Breakthroughs: Deep Integration of Intelligent Sorting and Flexible Vibration

Multi-Axis Vibration Control and Material Posture Adjustment System

The equipment employs electromagnetic-pneumatic composite drive technology to construct a six-degree-of-freedom vibration platform with three axes (X/Y/Z) + three rotations (pitch/yaw/roll):

- Adaptive Vibration Waveform Generation: Through 128 sets of piezoelectric ceramic drivers, 23 vibration modes such as sine waves, square waves, and pulse waves are generated in real time. In the feeding of micro springs for mobile phone camera modules, the system uses pulse vibration with a 0.1mm amplitude to avoid spring entanglement, reducing the damage rate from 12% in traditional vibratory bowls to 0.8%.

- Intelligent Material Posture Correction: Equipped with a high-speed camera (1000fps) for real-time monitoring of part postures, the AI algorithm adjusts part orientation through 3-axis rotational vibration. In the feeding process of medical syringe needles, the system increases the qualification rate of needles pointing upward from 65% to 99.7%, eliminating the need for manual secondary sorting.

Integration of AI Visual Sorting and Defect Detection

The equipment integrates a 5K ultra-high-definition industrial camera and laser triangulation system to construct an intelligent closed-loop of “identification-sorting-detection”:

- Micron-Level Defect Recognition: A deep learning model built-in with 300,000 part samples can identify defects such as 0.05mm-level scratches and deformations. In the feeding of automotive sensor terminals, the system automatically rejects unqualified parts, reducing the subsequent assembly defect rate from 3.2% to 0.1%.

- Dynamic Path Planning Algorithm: The optimal picking trajectory is automatically generated based on part shapes, and the six-axis robotic arm, combined with a vacuum adsorption device, achieves high-speed sorting at 0.5 seconds per piece. After application by an electronic component manufacturer, the feeding efficiency of 0402 规格 resistors increased threefold to 1,200 pieces per hour.

Modular Quick Changeover System

The equipment adopts a quick-plug vibration platform and intelligent parameter library design, supporting second-level switching of multi-category parts:

- 5-Minute Tooling Changeover: Dedicated vibration trays are provided for three typical part categories: electronic components (≤1mm), automotive parts (5-50mm), and medical consumables (1-20mm):

- Micro-part tray: Teflon-coated surface, vibration frequency 20-50Hz;

- Metal part tray: Built-in electromagnetic demagnetization device, amplitude 0.5-2mm;

- Fragile part tray: Elastic silicone cushion, acceleration ≤5g.

Through a hydraulic quick-locking device, the tray replacement time is compressed to 5 minutes, increasing changeover efficiency by 90% compared with traditional vibratory bowls.- Intelligent Extraction of Process Parameters: During changeover, the system automatically matches the optimal vibration scheme from 189 groups of preset process parameters based on the part CAD model, avoiding parameter deviations caused by manual debugging.

Application Scenarios in Practice: Dual Improvement of Efficiency and Yield

Case 1: Flexible Feeding of 3C Electronic Micro-Parts

In the feeding scenario of 0201 capacitors in a semiconductor packaging factory, the comparison between traditional vibratory bowls and flexible feeders is as follows:

| Process Type | Traditional Vibratory Bowl (3 Units) | Ruizhi Intelligence Flexible Feeder (1 Unit) |

| Changeover Time | 60 minutes | 8 minutes |

| Part Damage Rate | 8.7% | 0.5% |

| Feeding Efficiency | 300 pieces/hour | 900 pieces/hour |

| Energy Consumption | 12kW·h/shift | 5kW·h/shift |

Especially in the gold wire feeding process for IC packaging, the equipment uses gentle vibration with a 0.01mm amplitude and negative pressure adsorption picking to reduce the gold wire entanglement rate from 22% to 1.3%, providing stable feeding for subsequent bonding processes and increasing single-shift capacity by 200%.

Case 2: Precision Part Feeding for Medical Syringes

Aiming at the feeding of stainless steel needles for insulin syringes, the equipment demonstrates unique advantages:

- Pain Points of Traditional Processes: Needles generate burrs due to collisions in vibratory bowls, requiring manual secondary polishing, which takes 4 hours per batch (10,000 pieces), and the qualification rate after polishing is only 85%.

- Flexible Feeding Solution: Adopting a low-amplitude (0.3mm) + low-frequency (15Hz) vibration mode, combined with an air bearing tray to reduce friction, the needle burr rate is reduced from 15% to 0.3%. After application by a medical device manufacturer, the manual polishing process was eliminated, shortening the production time per batch to 1.5 hours and saving over 1.2 million yuan in annual costs.

Industry Impact: Opening the Era of Intelligent Feeding 4.0

With the surging demand for flexible production in the global manufacturing industry (it is expected that small-batch orders will account for 50% by 2025), flexible vibratory feeding technology has become a core standard for automated production lines. The R&D director of Ruizhi Intelligence pointed out that the equipment supports docking with MES systems through the OPC UA protocol, enabling real-time uploading of feeding data to the cloud and achieving full-process traceability from materials to finished products.

Currently, the equipment has been implemented in leading enterprises such as Foxconn, Medtronic, and Bosch, averagely reducing 8 sorting workers per production line and decreasing workshop floor area by 35%. Industry reports show that the flexible vibratory feeder market will grow at an average annual rate of 29% in the next three years. Equipment with AI vision and multi-axis vibration control will become the mainstream, promoting the thorough transformation of automated feeding from “粗放分拣” (rough sorting) to “intelligent flexibility”.

Technical Extension: The equipment’s multi-axis vibration control technology has obtained a national invention patent (Patent No.: ZL2024XXXXXX), and the AI vision system has passed ISO 13849 PLd safety certification. Ruizhi Intelligence will demonstrate the flexible feeding process of 01005 ultra-micro components at the Shenzhen NEPCON exhibition in June 2025, where visitors can closely observe the technical details of non-destructive sorting for 0.02mm-level parts.

#FlexibleFeeding #IntelligentVibratoryBowl #IndustrialAutomation #PrecisionManufacturing