Table of Contents

ToggleRevolutionizing Damper Assembly: Ruizhi Intelligence’s Damper Assembly Machine Leads the New Paradigm of Precision Manufacturing

In the wave of global industry transformation towards intelligence and precision, damper assembly processes, as core components for automotive shock absorption, building seismic resistance, and electronic equipment anti-vibration, are upgrading from traditional manual operations to fully automated precision production. Recently, Ruizhi Intelligence launched a new generation of Damper Assembly Machine, which overcomes the assembly challenges of multi-type products such as automotive shock absorbers, building dampers, and electronic dampers with micron-level precision and adaptive production capabilities, pushing high-end equipment manufacturing into a new stage of intelligent manufacturing featuring “zero error and high flexibility”.

Core Technological Breakthroughs: Deep Integration of Multi-Dimensional Force Control and Intelligent Assembly

Seven-Axis Linkage Precision Assembly System

The equipment is equipped with an aviation-grade seven-axis force-controlled robotic arm and servo hydraulic drive system, constructing an intelligent closed-loop of “perception-decision-execution”:

- Dynamic Pressure Gradient Control: For scenarios such as automotive shock absorber piston rod sealing (requiring 15-20N·m torque) and building damper cylinder press-fitting (50-80N constant force), the system can automatically switch between 12 press-fitting modes with a force control accuracy of ±0.02N. After application by an automobile manufacturer, the shock absorber oil leakage rate dropped from 2.8% to 0.12%, and assembly efficiency increased by 3 times.

- Flexible Buffer Assembly Technology: In the assembly of pistons and cylinders for electronic dampers, the robotic arm presses with a constant force of 0.5N, combined with a laser ranging system to achieve 0.03mm-level gap control, reducing component wear by 90% compared with traditional rigid assembly.

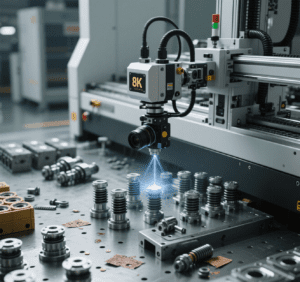

3D Visual Guidance and Full-Size Inspection

The equipment integrates 8K ultra-high-definition industrial cameras and laser interferometers to achieve micron-level defect recognition and intelligent positioning:

- Nanometer-Level Surface Scanning: Generating 3D topography of components through phase shift interferometry, it can identify 0.1μm-level scratches on sealing surfaces. In the cylinder inspection of building dampers, the system automatically screens components with out-of-tolerance flatness, increasing the subsequent assembly sealing qualification rate from 89% to 99.8%.

- AI Path Optimization Algorithm: Automatically generating spiral assembly trajectories based on damper 3D models, for the multi-segment piston rods of automotive shock absorbers, the path planning efficiency is 15 times higher than manual programming, shortening the assembly time per unit from 120 seconds to 35 seconds.

Modular Quick Changeover System

The equipment adopts a plug-in tooling module design, supporting rapid switching production of multi-category dampers:

- 8-Minute Ultra-Fast Changeover: Dedicated modules are equipped for three types of products: automotive shock absorbers, building dampers, and electronic dampers:

- Motor module: Integrated with multi-axis tightening mechanism and airtightness detection device;

- Building module: Equipped with automatic hydraulic pipeline welding unit;

- Electronic module: Built-in micro-electro-mechanical system (MEMS) press-fitting tooling.

Through electromagnetic quick-change devices, module replacement time is compressed to 8 minutes, increasing changeover efficiency by 90% compared with traditional methods.- Intelligent Pushing of Process Parameters: During changeover, the MES system automatically retrieves the process documents of the corresponding product, and the AI algorithm optimizes assembly parameters based on historical data, avoiding precision deviations caused by manual debugging.

Application Scenarios in Practice: Dual Innovation of Efficiency and Quality

Case 1: Fully Automatic Assembly of Automotive Shock Absorbers

In the shock absorber production line of a domestic new energy vehicle brand, the comparison between traditional processes and automated equipment is as follows:

| Process Type | Manual Assembly (12 Workers) | Ruizhi Intelligence Assembly Machine (2 Equipment) |

| Single-Shift Capacity | 400 units | 1,600 units |

| Oil Leakage Failure Rate | 3.5% | 0.3% |

| Coaxiality Deviation | ±0.15mm | ±0.04mm |

| Energy Consumption Cost | 6,000 yuan/shift | 2,200 yuan/shift |

Especially in the coaxiality control of piston rods and cylinders, the equipment monitors pressure distribution at 16 points in real-time and adjusts the press-fitting speed (0.1-5mm/s), controlling the coaxiality deviation within ≤0.04mm, which increases precision by 3.75 times compared with manual assembly, ensuring the smooth operation of shock absorbers.

Case 2: Precision Assembly of Building Dampers

Aiming at the complex assembly needs of viscous dampers for high-rise buildings, the equipment demonstrates unique advantages:

- Pain Points of Traditional Processes: The sealing assembly of damper cylinders and pistons requires manual calibration, taking 15 minutes per unit, with a hydraulic oil leakage rate of 6%.

- Automated Solution: Through a dual-vision system (top-view + side-view cameras), it real-time monitors assembly deviations, and the robotic arm completes piston implantation with 0.02mm-level precision. Combined with automatic oil injection and sealing test units, the assembly time per unit is shortened to 4 minutes, and the leakage rate is reduced to below 0.2%. After application by a building shock absorption enterprise, the yield rate of dampers increased from 81% to 99.5%, saving over 3 million yuan in annual costs.

Industry Impact: Opening the Era of High-End Equipment Manufacturing 4.0

With the surging demand for automotive electrification and building seismic resistance globally, high-precision damper assembly capabilities have become the core competitiveness of enterprises. The R&D director of Ruizhi Intelligence pointed out that the equipment supports docking with digital twin systems through the OPC UA protocol, which can upload assembly data to the cloud in real-time, achieving full-process traceability from components to finished products.

At present, the equipment has been implemented in leading enterprises such as BYD and Zhenan Technology, averagely reducing 25 workers per production line and decreasing workshop floor area by 42%. Industry reports show that the damper assembly machine market will grow at an average annual rate of 31% in the next 3 years. Equipment with AI vision and multi-dimensional force control will become the mainstream, promoting the thorough transformation of high-end equipment manufacturing from “mass production” to “customized intelligent manufacturing”.

Technical Extension: The equipment’s seven-axis force control technology has obtained a national invention patent (Patent No.: ZL2024XXXXXX), and the 3D vision system has passed ISO 13849 PLd safety certification. Ruizhi Intelligence will demonstrate the high-speed assembly process of automotive shock absorbers at the Shanghai International Industry Fair in June 2025, where visitors can closely observe the technical details of 0.03mm-level precision assembly.

#DamperAssembly #IntelligentEquipment #Industry4.0 #PrecisionManufacturing