If Industry 4.0 is centered on “automation and efficiency”, then Industry 5.0 represents the transformation of industry towards “human-centricity and sustainability”. Industry 4.0 makes manufacturing more efficient and intelligent, while Industry 5.0, building on this foundation, endows manufacturing with new value connotations.

Evolution of Industrial Transformation: From the Steam Age to the Intelligent New Era

Since the first Industrial Revolution, the industrial landscape has been constantly evolving. Steam power, electrification, informatization, and intelligentization have successively driven profound changes in manufacturing. Entering the 21st century, Industry 4.0, as the core concept of modern manufacturing, marks the comprehensive integration of intelligentization and digitalization. Nowadays, Industry 5.0 is emerging. It not only inherits the technological progress of the previous stage but also emphasizes the core role of humans in the future industrial ecosystem.

Industry 4.0: The Cornerstone of Intelligent Manufacturing

Industry 4.0 (the Fourth Industrial Revolution) aims to improve manufacturing efficiency through digital and intelligent means. Its core features are high automation, real-time connectivity, and data-driven decision-making.

Core Technologies

- Internet of Things (IoT): Enables interconnection between machines, equipment, and systems, supporting real-time data exchange.

- Artificial Intelligence (AI) and Machine Learning (ML): Enhance automation through intelligent algorithms, enabling predictive maintenance and autonomous optimization.

- Big Data and Analytics: Help enterprises extract insights from massive data to improve the scientificity of decision-making.

- Cyber-Physical Production Systems (CPPS): Integrate physical equipment and digital systems to build highly collaborative smart factories.

- Cloud Computing: Support remote access, resource sharing, and scalability of industrial processes.

Main Goals

- Improve production efficiency

- Reduce costs

- Enhance productivity

- Achieve real-time monitoring and autonomous optimization

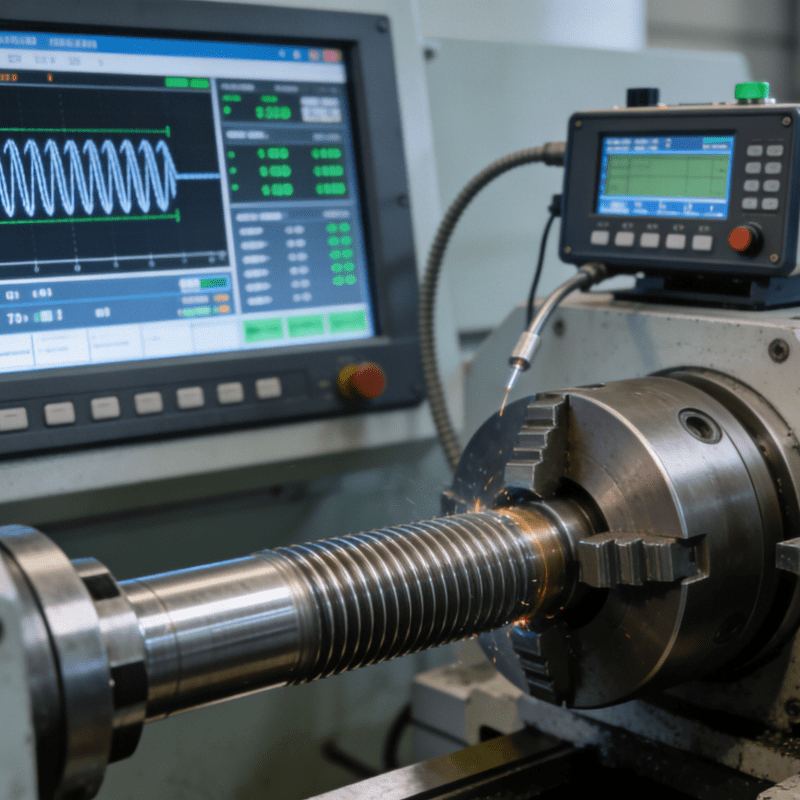

Under the framework of Industry 4.0, factories tend to operate in an intelligent mode of “self-perception, self-learning, and self-regulation”. For example, the Roboter-Vision-Positionierung Automatischer Folienapplikator, relying on robot vision positioning technology, can achieve high-precision automatic film application, significantly improving production efficiency and consistency in fields such as electronic components and auto parts, and has become a typical application equipment for Industry 4.0 automated production.

Industry 5.0: Human-Centric Sustainable Industry

If Industry 4.0 is centered on “automation and efficiency”, then Industry 5.0 represents the transformation of industry towards “human-centricity and sustainability”.

Core Features

- Human-Machine Collaboration: Machines no longer completely replace humans but work collaboratively with them, leveraging the creativity of humans and the efficient computing power of machines.

- Sustainability: Focus on environmentally friendly production, optimize energy use, reduce industrial waste, and promote green manufacturing.

- Resilience and Flexibility: Build industrial systems that can adapt to market fluctuations, supply chain disruptions, and environmental challenges.

- Ethics and Social Responsibility: Emphasize ethical artificial intelligence, pay attention to workers’ well-being and social inclusiveness, and promote responsible industrial development.

Strategic Significance

The emergence of Industry 5.0 is not just a technological upgrade but also a reflection of social values. It combines technological progress with human values to ensure that innovation results serve both economic development and the well-being of the environment and society.

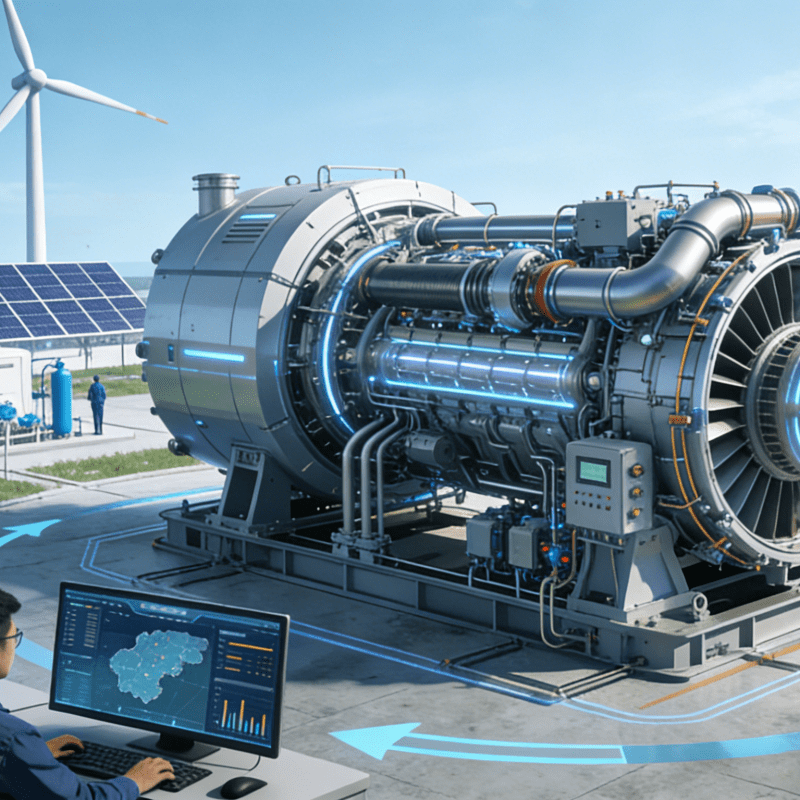

The Role of Cyber-Physical Production Systems (CPPS) in Industry 4.0 and 5.0

Role in Industry 4.0

As the core support of Industry 4.0, CPPS helps the manufacturing industry achieve:

- Enhanced automation: Machines can operate autonomously, reducing human intervention.

- Real-time data processing: Enable predictive maintenance and rapid response to improve production continuity.

- Optimized quality control: Real-time monitoring of production to reduce defect rates and improve product consistency.

Development in Industry 5.0

With the arrival of Industry 5.0, CPPS not only assumes the role of automation but also undertakes the “human-centric” mission:

- Human-machine collaboration: Machines and humans work together to expand creative production.

- Green manufacturing: Achieve more environmentally friendly production models through resource optimization and emission reduction.

- Resilience and adaptability: The system can quickly recover and adjust under external shocks to maintain industrial stability.

Key Differences Between Industry 4.0 and Industry 5.0

The Future of Industrial Transformation

Industry 5.0 is not just a technological iteration but also a reshaping of social and industrial values. The future industrial ecosystem will:

- Integrate the advantages of humans and machines: Collaboration between automated execution and human creativity.

- Promote green and circular economy: Achieve sustainable development.

- Strengthen ethics and inclusiveness: Ensure worker safety, respect diversity, and build a fair working environment.

How Organizations Can Achieve the Transition

Enterprises that have adopted Industry 4.0 can move towards Industry 5.0 in the following ways:

- Introduce sustainable practices and adopt green strategies in energy management, waste disposal, and carbon emissions.

- Promote human-machine collaboration, redefine job roles, and enable workers to complement intelligent machines.

- Regulate AI ethics to ensure transparency, fairness, and workers’ rights.

Conclusion

Industry 4.0 makes manufacturing more efficient and intelligent, while Industry 5.0, on this basis, endows manufacturing with new value connotations: human-centricity, green sustainability, and resilience. The future industry will no longer simply pursue maximum efficiency but strive to balance technology and human values.

The ultimate goal of industry will not just be to produce more, but to produce better — more environmentally friendly, more human-centric, and more socially responsible.