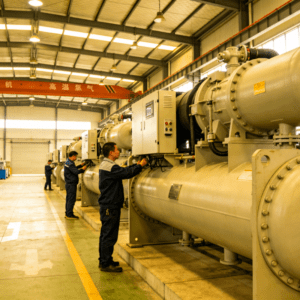

On February 3, a high-temperature steam heat pump unit independently developed by Dongfang Electric Machinery, a subsidiary of Dongfang Electric Group, was successfully put into operation at Sinopharm Taiji Fuling Pharmaceutical Factory. As the first tonnage-class ultra-high-temperature steam heat pump with adaptive variable working conditions in China’s pharmaceutical industry, its successful commissioning marks an important breakthrough for Dongfang Electric in achieving high-efficiency waste heat utilization in the pharmaceutical sector.

High Efficiency and Energy Conservation for Pharmaceutical Scenarios

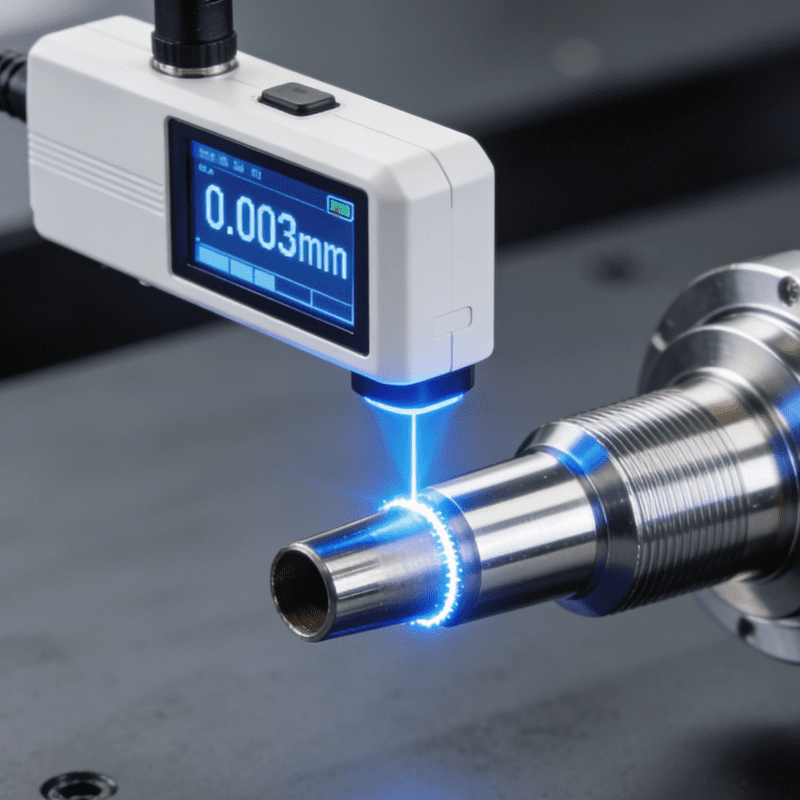

Tailored to the energy consumption characteristics of typical pharmaceutical manufacturing scenarios, the project delivers an all-new green and energy-saving solution. A new high-temperature steam heat pump and booster system has been built, with an input electric power of approximately 330 kW and a rated heating capacity of 890 kW. The measured COP (Coefficient of Performance) remains as high as 2.7 even under a large temperature rise. The system adopts innovative waste heat recovery technology, with recovered heat directly reused in production processes.

Integrated Intelligence and Automation

As a high-parameter, non-standard customized project, it integrates multiple systems including water, electricity, compressed air and steam, and is equipped with remote intelligent control, featuring high technical integration and a high level of automation.

Dongfang Electric has overcome multiple technical challenges, achieving stable output of 165°C saturated steam even when the waste heat source temperature is as low as 40°C. The system adapts to pressure fluctuations in the main steam pipeline and flexibly supplies steam, enabling efficient collaborative operation of dual waste heat sources. By applying an intelligent optimal operation strategy, the overall energy efficiency of the system is further improved. By efficiently recovering heat from waste hot water with only a small amount of electricity, the heat pump can replace traditional steam generation methods using natural gas or coal-fired boilers, supporting energy conservation, carbon reduction and green transformation.

Replicable Technology for Zero-Carbon Development

At present, the steam parameters produced by Dongfang Electric’s high-temperature steam heat pumps can meet mainstream process requirements in pharmaceuticals, brewing, chemical engineering, food, printing and dyeing, and other industries. With outstanding advantages such as high recovery efficiency, zero emissions during operation, strong economic efficiency and a high degree of intelligence, the technology is highly replicable and scalable. It is of great significance for the development of zero-carbon parks and zero-carbon factories.