The Rise of Collaborative Robots: A New Trend in Industrial Automation

In the high-stakes environment of modern manufacturing, where skilled labor shortages collide with surging demand for precision manufacturing, a quiet revolution is unfolding: collaborative robots (cobots) are moving beyond factory floors into laboratories, clean rooms, and logistics hubs, working side-by-side with humans to tackle tasks once deemed too delicate or repetitive for automation.

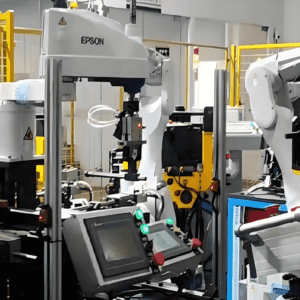

- Epson Enters the Fray: Birth and Mission of Its First Collaborative Robot

Epson, an industry leader with 40 years of expertise in industrial robotics, is now set to join this field—its first collaborative robot is 即将问世 (soon to be released). This lightweight, high-performance product aims to redefine standards of flexibility and hygiene across industries, with a planned launch later this year. More than just a machine, it responds to the most pressing challenges in today’s workplaces: from production lines grappling with labor gaps to pharmaceutical labs requiring sterile environments and extreme precision. Epson’s cobot seeks to bridge the divide between human creativity and robotic efficiency.

- Designed for Versatility: Lightweight Build with Powerful Performance

At first glance, Epson’s collaborative robot stands out for its ultra-lightweight frame: weighing just 17kg, it is easy to move and reconfigure, making it ideal for dynamic environments where production lines need overnight adjustments. Its controller features a compact design (440x205x135mm) and weighs less than 6kg, eliminating the need for bulky setups and freeing up valuable floor space in crowded facilities.

But its size is deceptive. The robot boasts impressive internal performance: a 6kg payload capacity and 900mm arm reach, sufficient to handle tasks ranging from assembling tiny electronic components to packaging precision pharmaceuticals. “We designed it to be a ‘chameleon,’” says a robotics engineer at Epson. “Whether sorting parts in a factory or transferring samples in a lab, it adapts seamlessly.”

- Perfect Fusion of Cleanliness and Durability: Design for Harsh Environments

For industries with strict cleanliness requirements—such as pharmaceutical labs, semiconductor factories, or medical device manufacturing—Epson’s collaborative robot sets a new benchmark. It meets ISO 14644-1 Class 5 standards, operating in environments with minimal airborne particles, which is critical for preventing contamination in drug production or microchip assembly. Its IP54 rating further enhances reliability, shielding it from dust and splashes to ensure stable operation in complex or tightly controlled settings.

The design itself reflects a focus on hygiene: smooth curves and a sleek chassis eliminate screw holes and sharp edges—spots where dirt or bacteria might hide. “In a clean room, every crevice is a potential risk,” explains a quality control expert at a leading biotech company. “Epson’s design is forward-thinking—no dead corners, no gaps, and it wipes clean in seconds.”

Human-Centric Intelligent Design: Simplifying Operation, Enhancing Collaboration

Epson’s collaborative robot emphasizes not only strength and precision but also efficient human-robot collaboration. Programmers will benefit from its compatibility with Python—one of the most widely used programming languages—lowering the barrier to customization. For factory workers, this means faster training and easier task adjustments, whether reprogramming to handle new parts or adjusting speed for delicate operations.

This user-centric design aligns with broader trends in robotics: moving from “set-it-and-forget-it” industrial arms to machines that learn and adapt alongside humans. “Cobots should not replace workers but make their jobs easier,” says a manufacturing consultant. “Epson’s focus on usability means even small teams can integrate automation without hiring specialized technical staff.”

- From Japan to Global Markets: Phased Rollout and Deep Expertise

Epson plans to launch the cobot first in Japan and Europe—regions where precision manufacturing and strict regulatory standards (such as those in the pharmaceutical industry) create urgent demand for cutting-edge automation. It will then expand to other regions, targeting industries including automotive assembly, e-commerce logistics, and academic research labs.

This launch marks a new phase for Epson. Forty years ago, the company initially designed robots for its own factories; today, over 150,000 Epson robots are deployed worldwide, with this valuable experience laying a solid foundation for its cobot development. “We have witnessed firsthand the needs of manufacturers and labs,” says the head of the company’s robotics division. “This cobot is more than a product—it is our solution to the challenges our customers have faced for years.”

- Future Outlook: Seamless Collaboration, Reshaping Work Scenarios

As the cobot nears release, its potential to reshape workplaces is clear: in manufacturing, it can take over repetitive tasks like screwdriving and inspection, allowing human workers to focus on problem-solving and quality control; in life sciences, it can handle hazardous or high-precision tasks, reducing human error in drug development; in logistics, its lightweight design makes it a promising fixture in warehouses for sorting packages or assisting with inventory checks.

But perhaps its greatest strength is adaptability. In a world where industries evolve rapidly—where a factory might shift from producing smartphones to medical devices in weeks—Epson’s cobot is ready to keep pace. “The future of work lies not in robots or humans alone, but in collaboration between them,” says a robotics industry analyst. “Epson’s new cobot is a blueprint for this future: compact, intelligent, and ready to excel.”

For Epson, this is more than a product launch—it reaffirms its legacy. From its first factory robots to this latest cobot, the company’s journey mirrors the evolution of automation: from machines that “replace human work” to partners that “work alongside humans.” In this partnership, the next wave of productivity and innovation is just beginning.

Introduce the application fields of Epson SCARA robots

What are the main technical parameters of Epson SCARA robots?