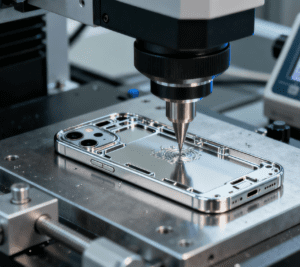

CNC precision machining (Computer Numerical Control) is an advanced manufacturing technology that uses computer technology to control machining equipment for precision operations. It can automatically control processes such as cutting, milling, and drilling, significantly improving machining precision and production efficiency. As the demand for high-precision and high-efficiency products in modern manufacturing continues to grow, CNC precision machining has become a crucial tool for improving production quality and enterprise competitiveness. This article will delve into the advantages and application fields of CNC precision machining, as well as how to select a suitable machining factory, helping enterprises better understand and apply this key technology.

What is CNC Precision Machining?

CNC precision machining technology utilizes computer numerical control systems to control mechanical equipment for high-precision machining through program instructions. Compared with traditional manual machining methods, CNC machining can significantly improve machining precision and consistency, reduce human operational errors, while greatly shortening production cycles and lowering production costs. This technology is widely applied in aerospace, automotive manufacturing, electronic equipment, medical devices and other fields, meeting the stringent requirements for high quality and high precision across different industries.

Key Advantages of CNC Precision Machining

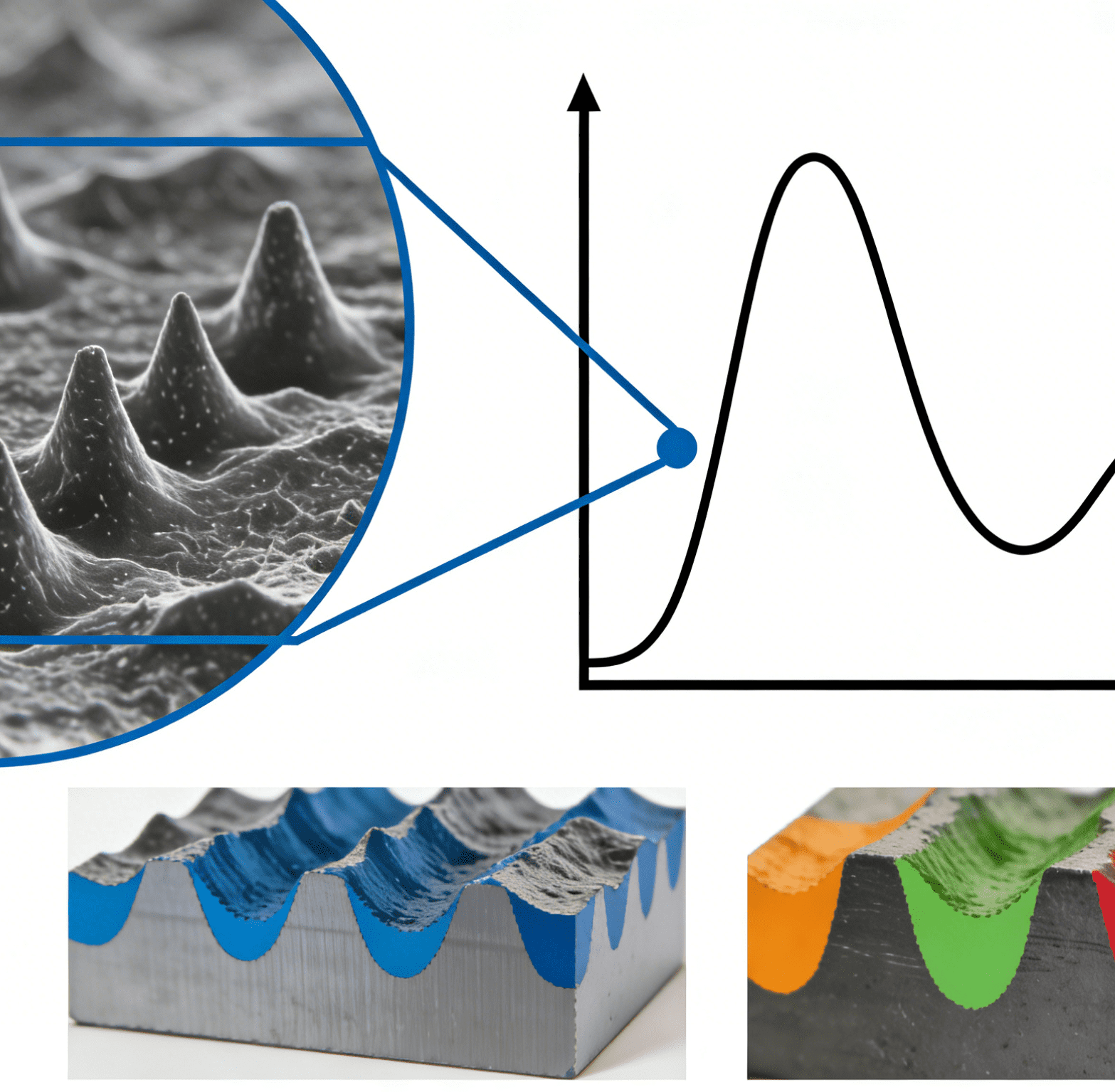

– High-precision machining: CNC precision machining technology can achieve micron-level precision control, meeting the ultra-high precision requirements of industries such as aerospace and medical equipment. The computer-controlled machining process greatly reduces human operational errors, ensuring minimal dimensional tolerances for each part.

– Improved production efficiency: Due to the high automation level of CNC precision machining equipment, it can operate continuously for long periods, significantly boosting production efficiency. The program-controlled machining process not only saves manual operation time but also reduces the frequency of production line shutdowns, thereby improving overall production capacity.

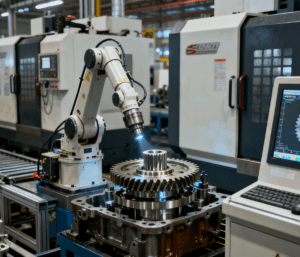

– Flexible machining capability: CNC equipment supports the machining of complex shapes and diverse materials, enabling manufacturers to design and produce various customized components. This is particularly important for products requiring high precision and complex structures, especially in aerospace, automotive and electronic product manufacturing.

– High repeatability and stability: The high repeatability of CNC precision machining ensures consistent quality for each part in mass production. Even in large-batch production, part consistency is maintained, which improves product reliability and uniformity, and reduces rework and waste caused by defective parts.

– Optimized material utilization: CNC precision machining effectively reduces material waste through precise cutting and forming technologies, thereby lowering production costs. This high-efficiency material utilization not only improves economic benefits but also plays a positive role in environmental protection.

Main Application Fields of CNC Precision Machining

CNC precision machining technology is widely used in multiple industries with high precision requirements. The main application fields are as follows:

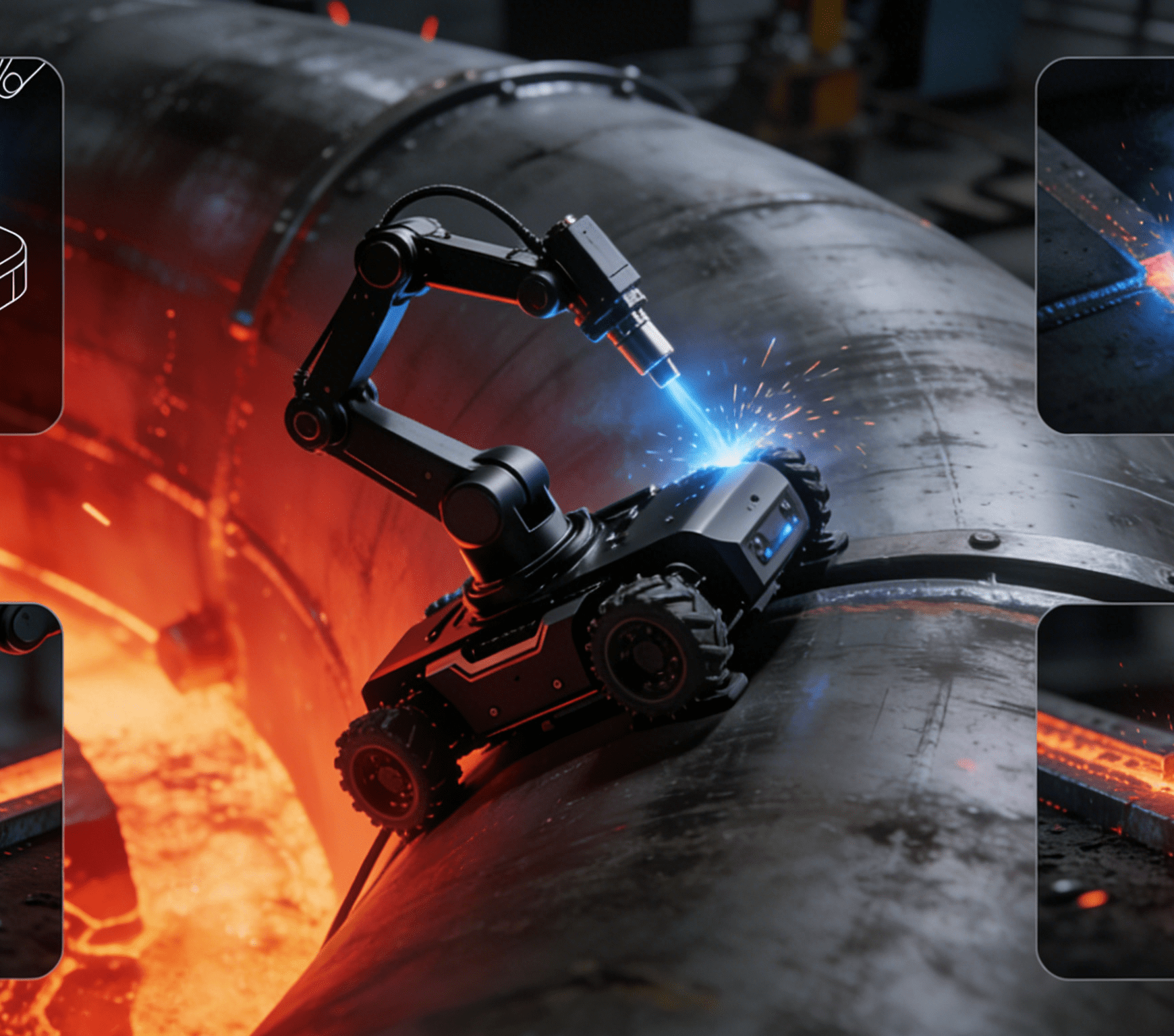

– Aerospace: The aerospace industry has extremely high requirements for the precision and reliability of components. CNC precision machining can provide high-precision machining for aircraft and engine parts. These components usually operate in extreme environments and must therefore meet strict performance standards.

– Automotive manufacturing: In automotive manufacturing, CNC precision machining technology is widely used in the production of key components such as body structural parts, engine assemblies, and transmissions. It ensures the precision of each part, thereby enhancing the performance and safety of the entire vehicle.

– Electronic equipment: In the electronic equipment industry, especially consumer electronics (such as mobile phones, computers, etc.), CNC precision machining is used to manufacture small and complex parts. High-precision machining ensures product quality and reliability.

– Medical devices: With the advancement of medical technology, the requirements for medical devices are constantly increasing. CNC precision machining can meet the strict hygiene, safety and functional standards of medical equipment, ensuring the high quality of medical products. For example, key components of nebulizers (a common medical device for respiratory treatment) rely on CNC machining to achieve micron-level precision of atomizing nozzles and housing structures, and the subsequent assembly process is supported by nebulizer assembly machines—these machines integrate the precisely machined components with high efficiency and consistency, further ensuring that the final nebulizer products meet clinical safety and performance requirements.

Technical Advantages of CNC Precision Machining

– Ultra-high machining precision: CNC precision machining technology can machine parts with minimal tolerances and meet the stringent precision requirements for components in modern manufacturing. Compared with traditional methods, CNC machining reduces human errors, thus ensuring consistent product quality.

– Automation-driven efficiency: CNC precision machining features a high level of automation, enabling 24/7 uninterrupted production and greatly improving production efficiency. Its high automation and easy operation allow enterprises to respond more quickly to market demands and shorten production cycles.

– Diversified machining capability: CNC equipment supports the machining of components with various complex shapes, which can be flexibly adjusted according to different needs to meet the machining requirements of different materials, shapes and specifications.

– Stability and high repeatability: The high stability and repeatability of CNC precision machining equipment ensure consistent machining quality of components during mass production. This is crucial for improving production quality and reducing the defective product rate.

How to Select a Suitable CNC Precision Machining Factory?

Selecting a suitable CNC precision machining factory is key to ensuring product quality and delivery cycles. The selection criteria are as follows:

– Qualifications and experience: Choosing a CNC machining factory with certifications (such as ISO 9001 certification) ensures compliance with international standards in quality management. Experienced manufacturers can better understand customer needs and provide professional machining solutions.

– Equipment and technical level: Advanced equipment and technical capabilities are the foundation for providing high-precision and high-efficiency machining services. Selecting manufacturers with modern CNC equipment can ensure product quality and delivery speed.

– Delivery capability and communication efficiency: Delivery capability and timely communication are crucial when selecting a machining factory. High-quality factories can guarantee on-time delivery and maintain good communication with customers during production to ensure the smooth progress of projects.

– Customer reputation and feedback: Refer to the evaluations and feedback from other customers to understand the factory’s reputation in the industry. A manufacturer with a good reputation usually provides high-quality machining services and reliable customer support.