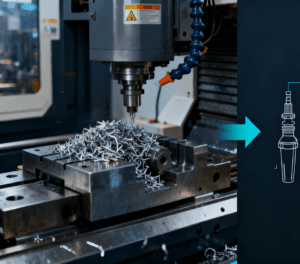

In the field of CNC (Computer Numerical Control) machining, especially CNC precision machining, the issue of chip evacuation has always been a key factor affecting machining quality and efficiency. As the precision requirements for precision part machining continue to rise, the choice of chip evacuation methods is facing a decision between “simple countermeasures” and “in-depth transformation”.

Simple Countermeasures: Application Scope and Inherent Limitations

Traditionally, many enterprises have adopted simple countermeasures for chip evacuation in CNC precision machining. A common method is to use cutting fluid flushing to wash chips away from the machining area. This approach can remove chips to a certain extent and ensure the continuity of machining. For some CNC machining scenarios with low precision requirements, regular chip shapes, and small chip volumes, simple cutting fluid flushing combined with the machine tool’s own chip evacuation device may be sufficient to meet the needs.

However, in precision part machining, this simple response method exposes many drawbacks. The limitations of simple countermeasures first manifest in their impact on machining precision. If tiny chips cannot be discharged in a timely and thorough manner, they may remain in the machining area. During subsequent machining processes, these chips may be caught between the cutting tool and the workpiece, leading to increased tool wear and even scratches on the workpiece surface—seriously affecting the dimensional accuracy and surface quality of precision parts. Secondly, chip accumulation affects the cooling effect of the cutting fluid. A large amount of accumulated chips hinders the normal circulation of the cutting fluid, causing the temperature of the machining area to rise and further leading to thermal deformation of the workpiece. This is an issue that cannot be ignored for CNC precision machining with high precision requirements.

In-depth Transformation: Core Directions of Chip Evacuation Technology

Given the shortcomings of simple countermeasures, in-depth transformation of chip evacuation technology is particularly necessary. One direction of transformation is the adoption of advanced chip evacuation equipment. For example, vacuum chip evacuation systems have demonstrated unique advantages in precision part machining. Through strong suction, they can quickly suck chips away from the machining area, avoiding chip accumulation and secondary pollution. This type of system is particularly suitable for scenarios where fine chips are generated during machining—such as the CNC processing of components for biological indicator assembly machines. As core equipment for medical sterilization monitoring, biological indicator assembly machines require ultra-high cleanliness and precision in their structural parts (e.g., sealed cavities, precision nozzles); even micro-sized chips can cause contamination or blockage, affecting the accuracy of sterilization detection. The vacuum chip evacuation system, combined with the assembly machine’s pre-processing cleanliness requirements, ensures that machining chips are completely removed before components enter the assembly process, laying a foundation for the reliable operation of biological indicator products.

Intelligent chip evacuation is also an important trend in in-depth transformation. With the help of sensors and control systems, it can real-time monitor the volume, shape, and distribution of chips generated during the machining process, and automatically adjust chip evacuation strategies based on this data. When an increase in chip volume is detected, the chip evacuation intensity is automatically increased; for chips of different shapes, the intelligent system can control the corresponding chip evacuation device to clean them in the most effective way.

In addition, optimizing the coordinated cooperation between machining processes and chip evacuation methods is also key to in-depth transformation. By reasonably selecting cutting tools, cutting parameters, and machining paths, the volume of chips generated and the degree of chip adhesion can be reduced, making chip evacuation smoother. For instance, when machining some difficult-to-cut materials, choosing appropriate tool coatings and cutting fluids can not only reduce cutting force but also improve chip morphology, facilitating chip evacuation.

Inevitable Trend: The Value of In-depth Transformation for Precision Machining

In CNC precision machining, the issue of chip evacuation can no longer be addressed with simple countermeasures. As the precision requirements for precision part machining continue to increase, in-depth transformation of chip evacuation technology is an inevitable trend. Only by introducing advanced chip evacuation equipment, realizing intelligent chip evacuation, and optimizing the coordination between machining processes and chip evacuation can we effectively solve the chip evacuation problem, improve the quality and efficiency of CNC precision machining, and promote the CNC machining industry to a higher level.