China’s Independently Developed Marine Engineering Intelligent Welding Robot Completes Integration, Bridging Technological Gaps

As the steel framework of deep-sea oil and gas equipment gradually takes shape amid welding sparks, a long-standing technological gap is being quietly bridged. On August 11, CNOOC Engineering announced that China’s independently developed intelligent welding robot equipment system for marine engineering flexible manufacturing has completed integration in Tianjin and officially entered the testing and acceptance stage. This equipment, which combines a “steel arm” with a “smart brain”, not only marks a major breakthrough in China’s flexible manufacturing field for key nodes of marine oil and gas equipment, but also adds a solid foundation to the confidence of “Made in China” in deep-sea energy development.

The “Precision Tailor” of Marine Engineering: High-Tech Integration in Intelligent Welding Robots

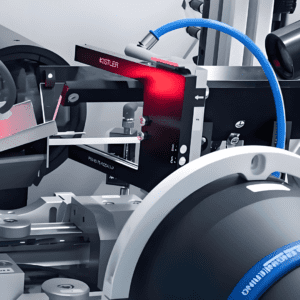

The flexible manufacturing intelligent welding robot can be called a “precision tailor” in the marine engineering field. Equipped with visual recognition “eyes”, it can flexibly handle various types of customized welding tasks in complex environments. Its research and development involves interdisciplinary integration of mechanical engineering, artificial intelligence, sensing technology, etc., with extremely high requirements for intelligent decision-making and environmental perception. Currently, only a few countries in the world have mastered this “precision craft on the fingertips”.

Key Achievements of the “14th Five-Year Plan” Project: Versatile and Localized Intelligent Robots

As a key achievement of the major scientific and technological project in the marine oil and gas engineering industry during the “14th Five-Year Plan” period, the 3 sets of intelligent robots integrated this time can be called “all-rounders”: they can not only complete intelligent assembly and welding of pipe node prefabrication, but also be competent for welding operations of block nodes and deep-water jacket reinforcing rings. What is more encouraging is that the maximum load capacity of a single machine for workpieces reaches 30 tons, the design life is 20 years, the core software and process library have achieved 100% localization, and the hardware localization rate exceeds 80%. Behind these figures is the complete filling of the technical gap in China’s marine engineering intelligent welding equipment field.

In the entire chain of marine engineering equipment manufacturing, the tentacles of intelligent upgrading are constantly extending. For example, the Automatic sorting, refining and tray loading equipment that provides support for welding accessories, through the collaboration of machine vision and robotic arms, realizes the full-process automation of parts from disordered incoming materials to precise classification, fine grinding and then standardized tray loading, laying a solid front-end foundation for the efficient operation of intelligent welding robots and forming an intelligent closed loop of “sorting – refining – welding”.

Innovative Solutions to Welding Precision Challenges: Empowering Robots with Advanced Capabilities

Facing the industry pain point of difficult control over welding precision of marine engineering structures, the CNOOC Engineering team innovatively put forward the concept of “transforming customized products into standard products, and extending standard products to standard components”. They have overcome many technical difficulties such as variable cross-section welding groove recognition and complex path planning, enabling the robot to possess more than 10 domestic initiative capabilities including weld AI visual recognition, 3D laser intelligent assembly, and multi-layer and multi-pass intelligent welding sequence arrangement. Now, with the press of the start button, the robot can independently complete the whole process of welding trajectory correction, intelligent back sealing, double-sided four-wire filling, etc., just like an experienced “master welder” operating precisely.

From “Weldable” to “Precise and Efficient Welding”: A Leap Fueling China’s Deep-Sea Ambitions

From “being able to weld” to “welding precisely and quickly”, behind this leap is China’s ambition in deep-sea equipment manufacturing. Next, the project team will focus on commissioning, acceptance and industrial application, and accelerate the implementation of the “R&D – verification – promotion” closed loop. Perhaps in the near future, when these intelligent robots operate efficiently in marine engineering bases, they will not only weld steel components, but also the confidence and future of China’s deep-sea energy development. In the race to cultivate new productive forces in marine energy, this intelligent equipment is writing the chapter of the leap from “Made in China” to “Intelligent Made in China” with sparks as its pen.

Core technologies of flexible automatic assembly equipment

What is the market size and development trend of flexible automatic assembly equipment?