With the chemical industry as its core business, Yihua Group covers phosphate ore mining, fertilizer production, chlor-alkali chemical industry, fluorine materials and other sectors. It has established more than 30 R&D centers and production bases nationwide, involving a wide range of raw materials, processes, and an extensive scope of safety inspection points. For example, material blockage and foreign matters during the belt transportation of phosphate ore will disrupt production; leaks of sulfuric acid, hydrochloric acid and other corrosive substances pose hazards to personnel and equipment. Therefore, it is critical to detect potential safety hazards such as powder leakage, liquid spillage, smoke, and belt deviation in a timely manner.

Empowered by Vision Large Models: Accurate Detection of Belt Spillage and Blockage

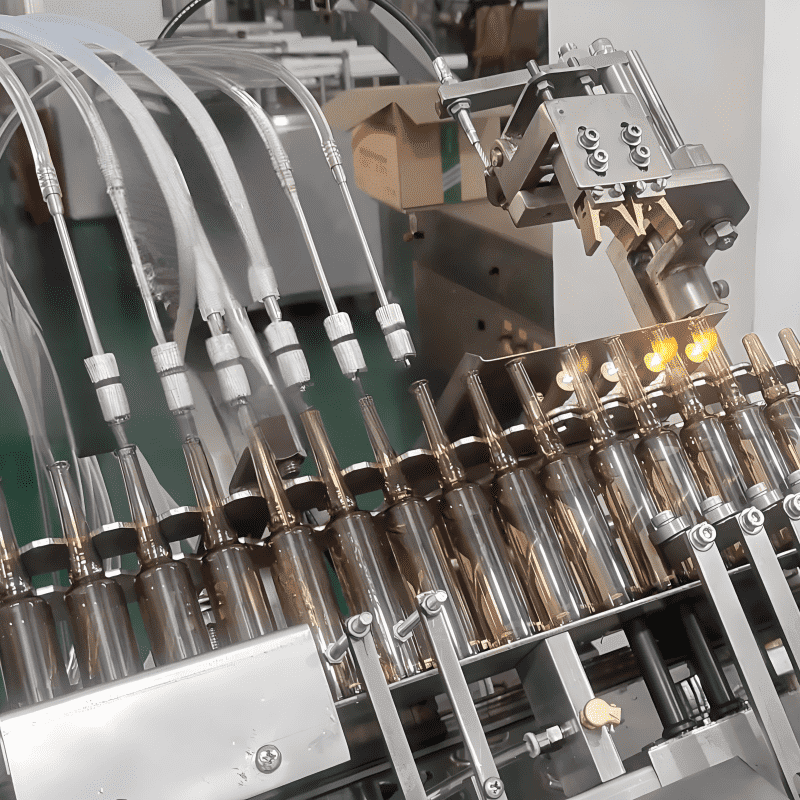

At Yihua Phosphorus Chemical Co., Ltd. (hereinafter referred to as “Phosphorus Chemical”), a subsidiary of Yihua Group, belt conveyors are responsible for the transfer of phosphate ore, serving as a key link to ensure continuous production. As the “artery” of the plant, long-term operation of belt conveyors brings “health risks”, including belt tearing, deviation, blockage and other issues, which not only reduce production efficiency but also create safety hazards.

To address this pain point, Hikvision has deployed an intelligent monitoring system at more than 100 key points of belt conveyors in Phosphorus Chemical. Through algorithms for deviation detection, bulk material detection, and belt blockage based on large models, the system analyzes the operating status of belts, accurately identifies deviations and changes in the relative position between belts and roller edges, and triggers an immediate alarm upon detecting anomalies.

The application of vision large models improves the target detection rate and effectively reduces the false alarm rate. This solution has successfully prevented equipment damage and material spillage caused by belt deviation and similar problems, and is expected to substantially cut down cleaning and maintenance costs each year.

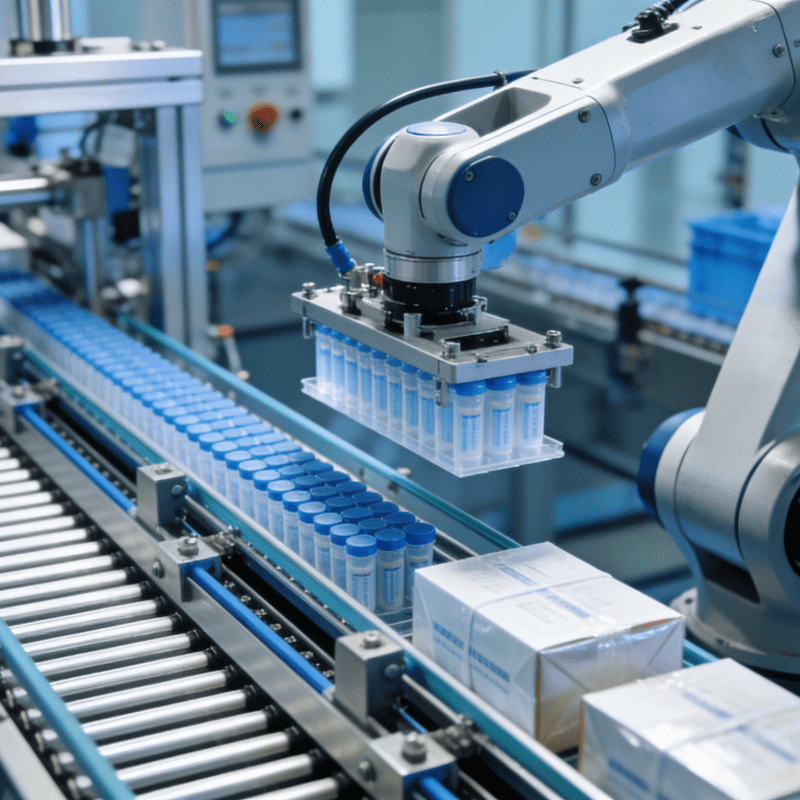

Over 90% Accuracy: AI Pinpoints Potential Safety Hazards in Production

Production sections manufacturing different products face diverse and complex safety hazards, such as risks of sulfuric acid and hydrochloric acid leakage, and chain safety incidents possibly triggered by powder blockage in equipment. These issues not only affect production continuity but also directly endanger the safety of personnel and installations.

At present, the intelligent inspection system has been deployed at more than 700 AI monitoring points covering over 500 key scenarios across 7 core production sections (installations) in Phosphorus Chemical, enabling accurate identification of powder leakage, liquid spillage, smoke and other anomalies. Integrated with vision large model technology, the overall detection accuracy of the AI inspection algorithm exceeds 90%. The detection results are linked with the smart platform, forming a closed-loop management mechanism from event perception, real-time alarm to response and feedback.

In addition, thermal imaging enables precise temperature measurement of pipelines, strongly supporting stable, efficient and safe operation of production processes from multiple dimensions.

In the past, full-coverage inspection required three shifts per day, with intensive patrols during each 8-hour shift, resulting in heavy manpower input and limited response efficiency. Today, supported by Hikvision AI intelligent inspection system, only one shift performing a single centralized inspection is needed to achieve more accurate risk identification and faster response.

Hikvision has also built a unified AI capability center for Yihua Group, turning technical accumulation into reusable platform capabilities to empower all its production bases. The system is widely applied in core scenarios such as process inspection, special operation supervision, and on-site hazard monitoring.

AR Panoramic “Single Map”: Efficient and Comprehensive Park Safety Management

Compared with the traditional model of monitoring park security through scattered window-based screens, the AR single map delivers more comprehensive and efficient integrated management.

At Xinyi Chemical, a subsidiary of Yihua Group, Hikvision has deployed an AR real-scene single map system. Based on high-point panoramic video and augmented reality technology, the system integrates multi-dimensional data including environmental monitoring data and hazard source information into the video feed in real time via point, line and surface labels through a real-scene map engine, forming a unified and visual management interface.

This architecture breaks down traditional information silos, realizes full-process visualization from data perception to command and dispatch, and effectively improves the collaboration efficiency and response speed of park safety management.