Table of Contents

ToggleBreaking the Dilemma of Multi-Variety and Small-Batch Production? The Secret to Flexible Automation

Scene Spotlight:

At 2 a.m. in an electronics factory workshop, worker Xiao Zhang stares at an order alert on the screen – a client suddenly adds an urgent order for 500 customized routers, demanding delivery within 3 days. However, the production line is still manufacturing old-model phone cases. Changing the line requires: ① Manually disassembling fixtures (at least 1 hour); ② Debugging robot programs (engineers are hard to recall at midnight); ③ Replacing conveyor rails (materials need re-adaptation)… Worse still, end-of-month accounting reveals that the three small-batch orders received last month actually incurred losses due to line-change wastage and overtime pay.

I. Three “Fatal Flaws” of Traditional Production Lines

1. Low Changeover Efficiency: The “Time Assassin” of Orders

- Concrete Scenario: During line changeovers, workers must manually unscrew over 20 screws to replace fixtures, copy programs to robot control cabinets via USB drives, and spend 30 minutes debugging material rails – each changeover halts production for 2-4 hours, drastically eroding the “effective production time” for small-batch orders.

- Critical Data: A car parts factory statistics show changeover time accounts for 35% of the production cycle, equivalent to each line “idling” for 120 days annually; more fatally, due to changeover delays, the factory lost 7 urgent orders last year, incurring losses exceeding 20 million yuan.

2. Poor Capacity Flexibility: The “Seesaw Trap” of Profits

- Peak Season Pain: A 3C OEM factory received a hot-selling headphone order during peak season but couldn’t rapidly expand production due to “rigid” lines, forcing workers into three shifts – defect rates soared from 1.2% to 4.7%, with rework costs eating 15% of profits.

- Off-Season Pain: During off-seasons, production equipment idles at 60%, with monthly depreciation + maintenance fees exceeding 800,000 yuan. Accepting small orders risks “earnings failing to cover costs,” trapping the factory in a dead cycle of “lose if accepted, lose more if rejected.”

3. Data Black Box: The “Invisible Funnel” of Costs

- Lack of Granularity: Manual recording of material wastage often counts in “boxes” rather than “units” – an electronics factory found that for a small-batch connector order, actual material costs were 22% higher than budget due to over-claimed screws and tape waste, only discovered during end-of-month reconciliation.

- Delayed Decision-Making: Without real-time cost calculation, the sales department accepts “apparently profitable” orders, while the production department finds unit costs exceed selling prices by 5 yuan (due to heavier equipment depreciation for small batches), but the signed orders must be fulfilled at a loss.

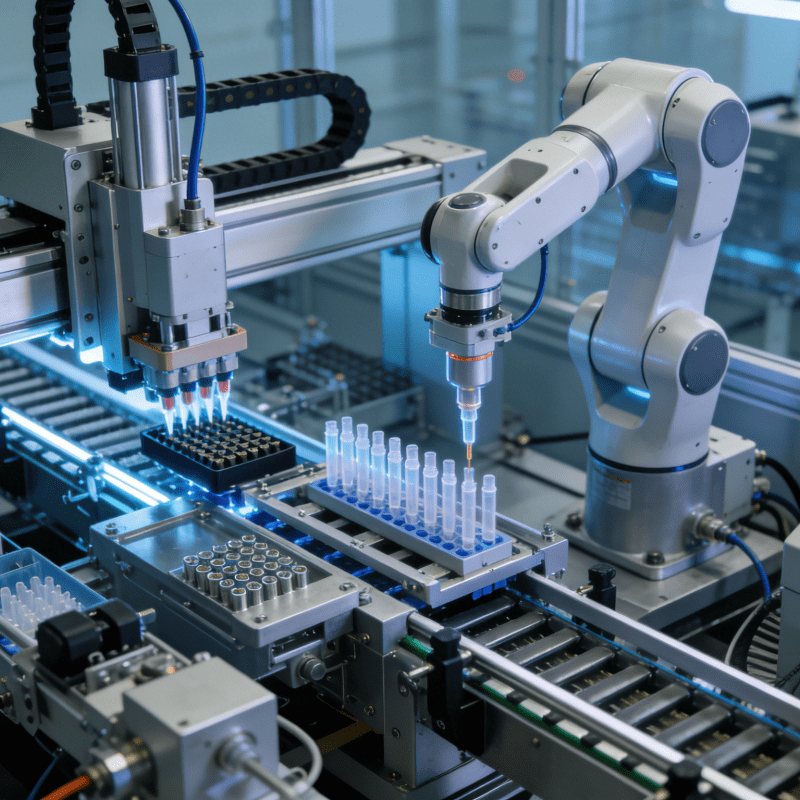

II. Three Technical Breakthroughs of Flexible Automation

1. “Second-Level Changeover”: A Collaborative Revolution of Hardware + Software

- Hardware: Modular “Plug-and-Play”

- Quick-Change Fixtures: Adopt dual structures of electromagnetic adsorption + mechanical locks, enabling robot ends to switch grippers in 0.5 seconds (e.g., from phone case grippers to smartwatch case grippers);

- Intelligent Rails: Conveyors integrate servo motors + laser sensors, automatically identifying material sizes (error ±0.1mm), adjusting rail spacing in 10 seconds to adapt to different product transportation.

- Software: Formula-based “One-Click Calling”

- MES systems pre-set over 100 production formulas (including speed, pressure, quality inspection standards), which workers call by scanning codes. AI can also automatically optimize parameters based on order history (e.g., for a router order, the system finds that “reducing speed by 2% can cut defect rates by 30%”).

- Case Study: After transformation, an electronics factory reduced changeover time from 2 hours to 8 minutes, shortened small-batch order delivery cycles by 40%, and gained an additional 35 million yuan in revenue last year by rapidly responding to “cross-border e-commerce emergency orders.”

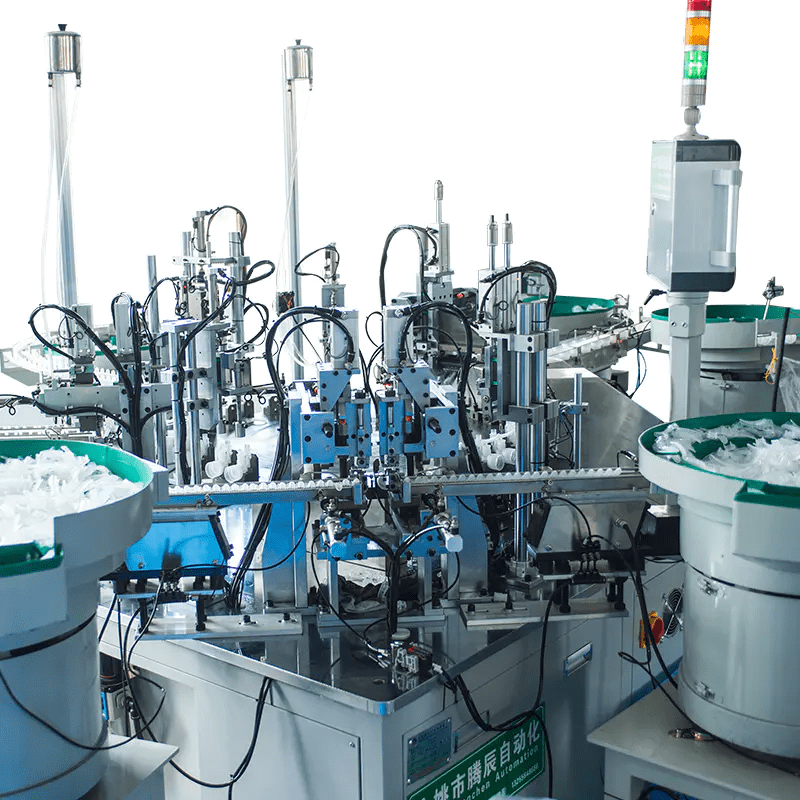

2. “Dynamic Capacity”: Splitting in Off-Season, Aggregating in Peak Season

- Off-Season: Parallel Production of “One into Many”

- A single production line can split into 3-5 independent workstations (e.g., left workstation making smart door lock panels, right making camera brackets), with edge controllers assigning tasks, increasing equipment utilization from 30% to 75%.

- Peak Season: Assault Production of “Many into One”

- The system automatically aggregates workstations and optimizes process connections using genetic algorithms (e.g., manufacturing casings before motherboards to avoid material backflow). A 3C OEM factory saw peak-season capacity surge by 60% while maintaining defect rates <1%.

- Case Study: An auto parts supplier serving both vehicle manufacturers (large batches) and after-sales markets (small batches) uses flexible lines to focus on vehicle orders in peak seasons and split for after-sales parts in off-seasons, reducing equipment idle costs by 82% and increasing small-batch order gross margins from 12% to 28%.

3. “Cost Transparency”: The Profit Scalpel of Data Closure

- Real-time Collection: Granularity to “Every Penny”

- Edge computing modules collect energy consumption (precise to 0.1 kWh), man-hours (to the minute), and materials (to individual screws) every second, automatically generating “small-batch order cost dashboards.”

- Digital Twin: Simulating Optimal Decisions

- Inputting order combinations (e.g., 300 routers + 500 smart sockets), the digital twin simulates over 1,000 scheduling plans and recommends the combination with the highest “gross profit – cost difference” (e.g., prioritizing orders with higher “profit per unit time”).

- Case Study: A factory once received an order for 1,000 customized devices. Digital twin calculations revealed unit costs exceeded the quotation by 8 yuan (due to complex processes + special materials), so they decisively rejected the order, avoiding an 80,000-yuan loss. Later, by optimizing scheduling, they increased profits on similar orders by 25%.

III. Three-Step Breakthrough Guide for Enterprise Transformation

1. Diagnosis First: Screening Projects with the “Flexibility Potential Model”

| Evaluation Dimension | Scoring Criteria (1-5) | Transformation Priority |

| Product Standardization | High proportion of general parts (e.g., 3C accessories) → high; many customized parts → low | ★★★★★ (Priority) |

| Order Fluctuation Frequency | >3 fluctuations monthly → high; stable → low | ★★★★☆ |

| Process Complexity | Multi-process, multi-material → high; single process → low | ★★★☆☆ |

- Example: The “smart socket + router” line of an electronics factory, due to high standardization and frequent fluctuations, achieved an ROI of 220% after transformation, recovering costs in 14 months.

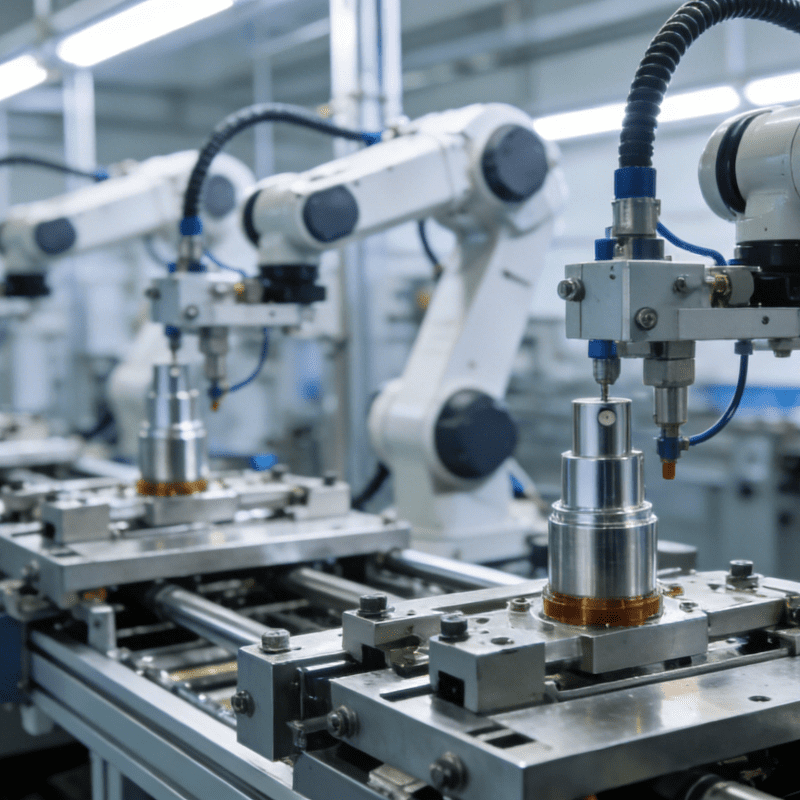

2. Gradual Transformation: From “Workstation-Level” to “Factory-Level”

Step 1: Bottleneck Workstation Transformation (e.g., sorting, assembly)

- First replace with intelligent sorting robots (visual recognition + quick-change fixtures, adapting to multi-variety materials) or upgrade to flexible assembly workstations (electric grippers automatically adapting to sizes). Invest 100,000-300,000 yuan to increase changeover speed by 50%.

Step 2: Production Line-Level Integration

- Connect workstations and unify data via MES systems to achieve “one-click line change + dynamic scheduling.” Invest 1-5 million yuan to shorten small-batch order delivery cycles by 60%.

Step 3: Factory-Level Interconnection

- Connect with ERP and WMS to build a digital twin factory, realizing full-process flexibility from “order → scheduling → delivery.” Invest over 5 million yuan to increase overall equipment efficiency (OEE) from 55% to 85%.

Tips: Prioritize cooperation with system integrators (e.g., Siemens, FANUC solution providers) to avoid self-developed pitfalls. A factory spent 2 years self-developing an MES with frequent bugs, while an off-the-shelf solution went live in 6 months.

3. Data Operation: Making “Small Orders” a Profit Engine

- System Integration: Real-time data flow among ERP (orders) → MES (production) → WMS (warehousing), generating small-order cost reports within 10 minutes.

- Decision Application: During scheduling, prioritize orders with the highest “profit per unit time = (selling price – variable cost) ÷ production duration” or combine orders (e.g., producing two small orders simultaneously to share materials/equipment and reduce marginal costs).

- Case Study: Through data-driven decisions, a hardware factory increased small-batch order profits by 20% – for example, rejecting “high-unit-price but long-production-time” orders and accepting “slightly lower-unit-price but fast-production” orders, boosting both capacity utilization and profits.

IV. Transformation Resistance and Solutions

1. “Too expensive to transform, slow to return?”

- Cost-benefit analysis: A factory invested 3 million yuan in transformation, increasing small-batch order gross margins from 15% to 32%, accepting 10 more small orders monthly (20,000 yuan profit per order), recovering costs in 12 months; plus reduced equipment idle costs and lower defect rates, the actual payback period may be shorter.

2. “Lack of talent, can’t operate?”

- Suppliers provide on-site training (e.g., robot operation, MES maintenance) to cultivate composite technicians who “understand processes + automation”;

- Outsource maintenance: Sign maintenance agreements with system integrators, paying monthly service fees (about 5% of transformation costs) to address after-sales concerns.

3. “Workers resist, fear unemployment?”

- Practice from an auto factory: 60% of workers transition to “automation operators” (monitoring equipment, handling exceptions) with 15% higher salaries; 30% switch to quality inspection (flexible lines have fewer defects, so inspection focuses on sampling); only 10% are optimized, achieving “human-machine coexistence.”

V. Industry Trend: Transform or Exit!

- Consumer-side pressure: By 2025, customized products will account for over 40% (e.g., customized phone cases, personalized home appliances). Consumers demand “uniqueness,” so production must be “flexible.”

- Policy dividends: Many regions offer smart manufacturing subsidies (e.g., 30%-50% of transformation costs). An enterprise in a certain province applied for flexible production line transformation and received a maximum subsidy of 2 million yuan.

Shocking Comparative Data:

- Enterprise A (after transformation): Small-batch orders increased from 20% to 50%, revenue grew by 12 million yuan, and profits increased by 3.5 million yuan (due to cost transparency, 15 loss-making orders were rejected).

- Enterprise B (without transformation): Lost 30% of small orders due to slow changeovers, suffered 8 million yuan in peak-season order rejections, and incurred 5 million yuan in off-season equipment idle losses, eventually being acquired after two years.

While your peers have turned “multi-variety small-batch” into a profit ace with flexible automation, are you still staying up for line changes and worrying about costs? The next issue, The Flexible Automation ROI Formula: Does Transformation Pay Off?, will teach you precise input-output calculation to spend money where it matters most!

(Click to follow and get real-world flexible automation insights first!)

#feeding system injection molding #automatic parts feeder #automated part feeding devices