- Navigating the Crossroads: Innovation and Pressure in Medical Device Manufacturing

- The medical device industry stands at the crossroads of unprecedented innovation and intense pressure. Driven by advancing technologies, evolving patient needs, and stringent global

- regulations, manufacturers are racing to deliver more sophisticated devices—from cutting-edge diagnostic tools to next-gen self-treatment equipment—while navigating shorter product

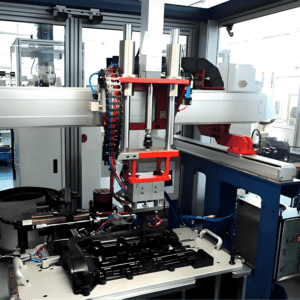

lifecycles and a hyper-competitive landscape. In this era of rapid change, the ability to adapt, scale, and accelerate time-to-market has become the cornerstone of success. For many, the key lies in reimagining assembly processes: moving beyond rigid automation to embrace flexible, scalable solutions that can keep pace with market demands. This is where Mikron Automation, a leader in precision assembly systems, steps in—blending decades of expertise with innovative engineering to empower manufacturers to turn challenges into opportunities.

- The Stakes: A Booming Market Demands Adaptive Assembly

With regulatory standards growing stricter, product lifecycles shrinking, and competition intensifying, medical device manufacturers face a critical imperative: transform their assembly operations to stay agile and future-ready. The market, valued at USD 455 billion in 2021 and projected to reach USD 658 billion by 2028 (Fortune), is being reshaped by a surge in complex devices, rising R&D investments (such as Johnson & Johnson’s USD 12 billion in 2020), and a growing focus on personalized healthcare—all of which demand assembly systems that are both adaptable and efficient.

“Today’s manufacturers need to slash development cycles, streamline validation, and launch products in lockstep with market needs,” says Jean-François Bauer, Head of Marketing and Business Development at Mikron Automation. “The winning edge goes to those who partner with providers that integrate flexibility and scalability into every solution. At Mikron, we’ve built our approach around being nimble enough to accelerate our customers’ production capabilities while optimizing their long-term investments.”

- Scalability: Growing with Confidence Through Process Equivalency

Mikron’s legacy of innovation, dating back to the 1970s, is rooted in its “building block” philosophy—designing standardized, modular assembly platforms that master complex processes while allowing for seamless expansion. This approach hinges on “process equivalency”: validating core assembly processes early, so manufacturers can start small and scale with certainty.

“A key advantage of our scalable model is that we develop and validate processes in the initial phase,” explains Bauer. “This means a manufacturer can launch with a semi-automatic line in as little as four months, using pre-validated processes. As demand grows, they can scale up to fully automated lines by reusing those validated processes—critical in pharma and medtech, where revalidation is costly and time-consuming.”

Mikron’s globally positioned sites offer scalable platforms tailored to regional market needs, letting manufacturers adjust production volume in line with demand. This flexibility drastically reduces risk, ensuring investments align with actual market traction.

- Speed & Agility: Balancing Flexibility with Productivity

The medical device landscape is increasingly defined by variety: more product variants, smaller batch sizes, and the need to run multiple devices on a single line. This shift demands assembly systems that can retool quickly without sacrificing efficiency—a challenge that Mikron addresses by integrating advanced technologies with strategic design.

“Speed and flexibility are often seen as opposing forces, but they don’t have to be,” notes Bauer. “By incorporating servo-driven robotics, flexible conveying systems, smart controls, and our Polyfeed flexible feeding system, we create lines that adapt to different product specs while maintaining high throughput.”

This balance is critical in a market where generic devices and new patient-centric solutions are opening niche segments. Manufacturers can now pivot between products, adjust to design tweaks, and respond to sudden demand shifts—all without overhauling their assembly infrastructure.

- The Mikron Difference: A Partner for the Entire Lifecycle

Swiss-engineered precision and a customer-centric mindset set Mikron apart. With 50 years of experience in complex assembly processes, the company acts as a one-stop partner, guiding customers from product development to full-scale production. Beyond hardware, Mikron offers end-to-end services: DFX (Design for Assembly/Manufacturing) analysis, pFMEA (Process Failure Mode and Effects Analysis), proof-of-principle trials, cleanroom assembly validation, and more. These services mitigate technical and financial risks, ensuring a smooth transition from concept to commercialization.

By consolidating expertise under one roof, Mikron eliminates the friction of working with multiple vendors, giving manufacturers the agility to act fast. Whether it’s launching a breakthrough device or scaling to meet global demand, customers gain a partner invested in their long-term success.

- From Survival to Thrival: The Catalyst for Sustainable Growth

In a medical device market where change is the only constant, scalability, flexibility, and expertise are no longer optional—they’re essential. Mikron Automation’s approach, built on modular innovation, process mastery, and comprehensive service, equips manufacturers to not just survive but thrive. By turning assembly lines into adaptive, future-ready assets, Mikron empowers its partners to accelerate innovation, meet regulatory demands, and deliver life-changing devices to patients faster. In this dynamic era, the right automation partner isn’t just a supplier—it’s a catalyst for sustainable growth.

What are the development trends of flexible automatic assembly equipment?

What is the market size and growth situation of flexible automatic assembly equipment?