4-Axis Robotic TV Panel Screw-Fixing System: Revolutionizing Display Assembly with Speed and Precision

In the fast-paced world of consumer electronics manufacturing, assembling large TV panels (ranging from 55″ to 100″+) with consistent precision is critical to meet market demands for sleek, defect-free displays. Traditional manual or semi-automated screw-fixing methods suffer from inherent limitations: slow cycle times (30–60 seconds per panel), positional errors (±0.5mm or worse), and high labor costs due to repetitive heavy lifting. The 4-Axis Robotic TV Panel Screw-Fixing System emerges as a game-changing solution, combining the agility of 4-axis SCARA robots with intelligent vision guidance to streamline panel assembly in high-volume production lines. This article explores its technical architecture, industrial applications, and role in driving next-generation display manufacturing.

- Core Technical Architecture: Synergy of Speed and Accuracy

The system integrates high-speed 4-axis robotics, AI-powered vision systems, and adaptive screw-driving modules to achieve rapid, error-free screw fixation on TV panels. Its modular design consists of three interdependent subsystems:

- High-Speed SCARA Robot Manipulation

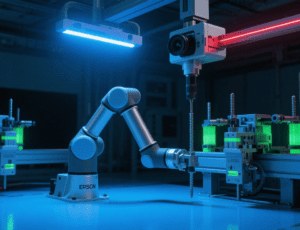

SCARA robots (e.g., Epson LS10 or Yamaha YK-XG series) are the backbone of the system, offering:

- Planar Motion Dominance: Achieving screw-fixing speeds of 8–12 screws per minute (2–3 times faster than manual labor) with repeatability of ±0.05mm, ideal for large panels requiring up to 50 screws per unit

- Payload Optimization: Lightweight carbon fiber arms capable of lifting 5–10kg (including end-effectors), reducing inertia for rapid acceleration/deceleration while maintaining stability

- Compact Work Envelope: Horizontal reach up to 1,000mm and vertical stroke up to 300mm, fitting seamlessly into narrow assembly cells alongside conveyor systems

- Vision-Guided Panel Alignment & Screw Positioning

A dual-camera vision system ensures millimeter-level accuracy:

- Overhead 2D Camera: Equipped with telecentric lenses to map panel edges and pre-drilled screw holes with 99.9% feature recognition accuracy, even for glossy or reflective surfaces (common in OLED/QLED panels)

- Laser Line Profiler: Scans panel curvature (up to 10° for curved TVs) and thickness variations (±0.2mm), adjusting screw insertion depth in real-time to prevent over-tightening or panel warping

- Dynamic Error Correction: Corrects for conveyor misalignment (up to ±15mm lateral shift or ±1° angular deviation) using predictive algorithms, ensuring screws align with mounting brackets on the TV frame

- Intelligent Screw-Driving Module

The end-effector combines precision mechanics with smart sensing:

- Multi-Spindle Tooling: Simultaneous driving of 2–4 screws (depending on panel size), reducing cycle time by 40% compared to single-spindle systems

- Torque-Control Sensors: Monitors tightening torque (0.5–5N·m range) to meet IPC-A-610 standards, preventing stripped threads or insufficient fixation

- Quick-Change Nozzles: Swaps between Phillips, Torx, or custom screw heads in <5 seconds, supporting diverse panel designs without manual retooling

- Industrial Applications: Streamlining Display Assembly

- Large-Screen TV Manufacturing

In 4K/8K TV production lines, the system excels at:

- Bezel-less Panel Fixation: Accurately positioning screws along ultra-narrow bezels (≤3mm width) of premium TVs, ensuring uniform pressure distribution and preventing display edge defects

- Modular Assembly Cells: Serving multiple workstations in parallel, with one robot handling up to 100 panels per hour (55″–75″ models), integrating seamlessly with AGVs for panel transport

Case Study: A leading Korean TV manufacturer reduced screw-fixing defects by 85% and shortened assembly cycle time by 30% after deploying 80 systems across its 75″+ production lines, achieving a throughput of 12,000 panels per day.

- Commercial Display & Digital Signage

For oversized displays (85″+) and curved LED video walls:

- Curved Surface Adaptation: Uses 3D vision data to generate adaptive screw trajectories, maintaining perpendicular insertion angles on concave/convex panels (curvature radius ≥500mm)

- Heavy-Duty Fixation: Handles M4–M6 screws for industrial-grade displays, with torque control up to 10N·m to withstand vibrations in public environments

- Notebook/Tablet Backcover Assembly (Extended Application)

While optimized for TVs, the system’s flexibility extends to smaller displays:

- Thin-Gauge Panel Handling: Places M1.6–M2 screws in laptop backcovers with ±0.1mm vertical alignment, preventing damage to underlying components (batteries, motherboards)

- Anti-Static Design: Conductive tooling and ionizing blowers eliminate electrostatic discharge risks during screw insertion into plastic or aluminum alloy backcovers

III. Competitive Advantages Over Traditional Methods

| Performance Metric | Manual/Semi-Automatic System | 4-Axis Robotic Screw-Fixing System |

| Screw Fixing Speed (per panel) | 30–60 seconds | 15–25 seconds (55″ panel, 20 screws) |

| Positioning Accuracy | ±0.5mm | ±0.05mm (X/Y axis), ±0.1mm (Z axis) |

| Torque Consistency | ±10% tolerance | ±2% tolerance (via real-time sensing) |

| Umstellungszeit (neues Panel) | 15–30 minutes | <2 minutes (recipe-based automation) |

| Labor Reduction (per line) | 4–6 operators | 1 supervisor (remote monitoring) |

| Defect Rate (screw-related) | 0.2–0.3% | <0.01% (with vision+torque dual checks) |

- Technological Innovations and Future Trends

- AI-Powered Process Optimization

Machine learning algorithms analyze historical data to:

- Predict optimal screw insertion order for new panel designs, reducing robot path length by 20%

- Detect subtle variations in panel material (glass vs. plastic backings) to adjust torque profiles, preventing stress-induced cracks

- Identify worn screw nozzles (via vibration analysis), triggering maintenance alerts before defects occur

- 3D Vision Upgrade for Complex Geometries

Integrating structured light or ToF sensors enables:

- Screw fixation on multi-layered panels (e.g., mini-LED backplanes with embedded heat sinks)

- Real-time compensation for thermal expansion (up to 0.3mm panel expansion at 50°C), critical for outdoor display assembly

- Collaborative Robot Integration

Dual-arm cobots (e.g., Universal Robots UR10e) with force-torque sensors are being developed for:

- Shared workspaces where robots handle heavy panels while humans inspect screw alignment, improving flexibility in mixed-model production

- Gentle handling of ultra-thin OLED panels (≤2mm thickness), using adaptive compliance to avoid pressure damage

- Energy-Efficient & Sustainable Design

Innovations include:

- Regenerative drives recovering 25% of braking energy during Z-axis motion

- Eco-mode reducing power consumption by 30% during idle periods

- Recyclable composite materials for robot arms and tooling, aligning with global ESG manufacturing goals

Conclusion

The 4-Axis Robotic TV Panel Screw-Fixing System represents a pivotal leap in display assembly automation, addressing the critical needs for speed, precision, and flexibility in large-panel manufacturing. By eliminating manual inconsistencies, reducing labor costs, and enabling data-driven quality control, it becomes an indispensable asset in smart factories aiming for zero-defect production. As the demand for larger, thinner, and more complex displays continues to rise, these systems will evolve—integrating AI, 3D vision, and collaborative capabilities—to set new standards for efficiency and reliability in the global electronics manufacturing landscape.

Keywords: 4-Axis Robotic Screw-Fixing System, TV Panel Assembly Automation, SCARA Robot Display Manufacturing, Vision-Guided Screw Insertion, High-Speed Panel Fixation, Torque-Control Screw Driving, Large-Screen TV Production, Smart Factory Display Solutions, AI-Powered Assembly System, Industrial Robot Vision Technology

#Large-Screen TV Panel Assembly Automation #Cold Formed Screw Placement System #Aerospace Display Panel Fastening