Table of Contents

ToggleAutomatic Hardware Part Feeding and Assembly: Revolutionizing Manufacturing Precision and Productivity

Introduction

In the industrial landscape, hardware components—ranging from screws and bolts to intricate metal fasteners and connectors—form the essential building blocks of countless products, from automotive engines to consumer appliances. Traditional manual and semi-automated methods for hardware part feeding and assembly are plagued by inefficiencies, including slow throughput (20–30 parts assembled per minute), high labor costs (accounting for 35% of production expenses), and inconsistent quality (defect rates up to 5%). Automatic hardware part feeding and assembly systems have emerged as a transformative solution, leveraging advanced robotics, intelligent control, and precision engineering to redefine manufacturing excellence.

A leading automotive parts manufacturer, for example, achieved a 250% increase in daily output after implementing an automated assembly line for engine bolts. The system reduced labor requirements from 12 operators per shift to just 2, while simultaneously improving assembly torque accuracy from ±10% to ±3%. This not only slashed production costs but also enhanced product reliability, leading to a 40% reduction in warranty claims related to loose or over-tightened components.

Technical Architecture: A Confluence of Precision and Automation

The efficacy of automatic hardware part feeding and assembly systems lies in their multi-layered technical design, integrating part handling, assembly, and quality control:

1. Automatic Part Feeding Sub-System

Vibratory Bowl Feeders

Vibratory bowl feeders are the workhorses of hardware part feeding. These devices use controlled vibrations to move parts along a helical track within a bowl-shaped container. As parts travel up the track, custom-designed chutes, slots, and rails orient them in the desired position. For example, in the assembly of computer chassis, vibratory bowls can precisely orient screws with their heads facing upwards, ensuring easy pick-up by robotic grippers. Advanced bowl feeders incorporate adjustable vibration frequencies and amplitudes, allowing quick adaptation to different part shapes and sizes.

Belt Conveyor and Sorting Systems

For larger or bulkier hardware components—such as washers, nuts, and large brackets—belt conveyors offer continuous feeding. These systems use sensors (e.g., photoelectric or inductive sensors) to detect part presence and position. Sorting mechanisms, like pneumatic pushers or electromagnetic diverters, separate parts based on size, shape, or orientation. In furniture manufacturing, belt conveyors can sort and feed metal connectors to assembly stations, ensuring that each component reaches the correct location in the production line.

Flexible Feeding Solutions

For complex or irregularly shaped parts, flexible feeding systems combine random part presentation with robotic picking. A layer of parts is spread on a flat surface, and 3D vision cameras scan them to generate digital models. AI-powered algorithms calculate each part’s position and orientation within milliseconds. Robotic arms equipped with custom grippers—such as parallel-jaw grippers for square nuts or vacuum cups for flat washers—then execute precise pick-and-place operations, enabling quick changeovers between different part types.

2. Automated Assembly Unit

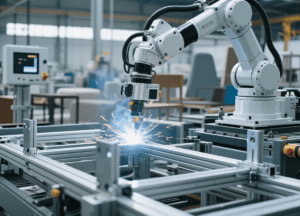

Robotic Assembly Cells

Multi-axis robotic arms, typically six-axis articulated robots (e.g., KUKA KR AGILUS or UR10e), serve as the assembly core. These robots offer high precision (repeatability of ±0.05mm) and flexibility, capable of tasks like screw driving, part insertion, and component fastening. In automotive suspension assembly, robots can tighten bolts to exact torque specifications (e.g., 80 ± 2 N·m) using electric torque guns, ensuring uniform joint strength.

Assembly Tooling and End-Effectors

Customized end-effectors are crucial for hardware assembly. For screw driving, robots use servo-driven screwdriver heads with built-in torque sensors, preventing over-tightening or under-tightening. For part insertion, pneumatic grippers with finger sensors can detect component presence and alignment. In electronics enclosure assembly, vacuum grippers pick and place metal heat sinks with precision, ensuring proper thermal contact with internal components.

3. Integrated Quality Control

Vision Inspection Systems

High-resolution cameras and image processing algorithms ensure assembly accuracy. Vision systems can detect missing parts, misaligned components, or incorrect fastener placement. For example, in appliance manufacturing, cameras can verify that all screws are present and tightened on a metal frame, rejecting any units with deviations. Deep learning models continuously improve defect detection, achieving accuracy rates exceeding 99.5%.

Force and Torque Monitoring

During fastening operations, force-torque sensors provide real-time feedback. These sensors measure the torque applied to each fastener and the axial force during insertion, ensuring compliance with design specifications. If a fastener fails to reach the required torque (e.g., a 10% deviation), the system halts assembly, flags the unit for inspection, and logs the data for traceability.

4. Control and Monitoring System

A combination of Programmable Logic Controllers (PLCs) and industrial PCs orchestrates the entire process. PLCs manage real-time operations, such as controlling conveyor speeds, robotic movements, and sensor inputs, with sub-millisecond response times. Industrial PCs handle higher-level tasks, including production scheduling, recipe management, and data analytics. Internet of Things (IoT) connectivity enables remote monitoring of machine performance, allowing manufacturers to track key metrics like Overall Equipment Effectiveness (OEE) and predict maintenance needs.

Industry Applications: Transforming Diverse Sectors

Automatic hardware part feeding and assembly systems have wide-ranging applications across multiple industries:

1. Automotive Manufacturing

Engine and Chassis Assembly

In automotive production, these systems handle the assembly of thousands of hardware components per vehicle. Robots automatically feed and tighten bolts on engine blocks, ensuring consistent torque values critical for performance and durability. For chassis assembly, the system can precisely position and fasten suspension components, reducing assembly time by 40% compared to manual processes.

2. Consumer Electronics

Smartphone and Laptop Assembly

In electronics manufacturing, automatic systems assemble metal frames, connectors, and screws with high precision. Vacuum grippers pick and place tiny metal components (e.g., SIM card tray springs), while servo-driven screwdrivers tighten micro-screws to exact torque requirements. This precision reduces the risk of component damage and improves product reliability.

3. Furniture Production

Metal Frame Assembly

For furniture manufacturers, automatic systems streamline the assembly of metal frames for chairs, tables, and cabinets. Robots feed and weld metal brackets, ensuring consistent joint quality. Vision systems inspect welds for defects, such as porosity or uneven bead formation, maintaining high aesthetic and structural standards.

4. Aerospace and Defense

Aircraft Component Assembly

In aerospace, where safety is paramount, automatic systems assemble critical hardware components, such as wing fasteners and engine mounts. The machines ensure that each bolt is tightened to strict torque specifications (e.g., 200 ± 5 N·m) and that all components are correctly aligned. Traceability features record every assembly step, enabling compliance with stringent aerospace regulations like AS9100.

Technological Frontiers: Shaping the Future of Assembly

1. Artificial Intelligence and Machine Learning Integration

AI and ML algorithms optimize assembly processes by analyzing production data in real-time. These technologies can predict part shortages, adjust feeding parameters based on material variations, and autonomously diagnose machine malfunctions. For example, an ML model can identify patterns in torque data to detect impending tool wear, triggering proactive maintenance.

2. Collaborative Robotics (Cobots)

Cobots are increasingly integrated into hardware assembly systems, enabling safe human-robot collaboration. In tasks requiring dexterity or complex decision-making, cobots assist human operators by handling repetitive or heavy lifting tasks. For instance, a cobot can pass pre-assembled hardware kits to an operator, reducing fatigue and increasing overall productivity.

3. Sustainable Manufacturing Features

Future systems will prioritize eco-friendly practices. Energy-efficient servo motors, recyclable material handling, and waste reduction through optimized part feeding will become standard. For example, machines may use algorithms to minimize scrap generation by reusing misfed or rejected parts, contributing to a circular economy.

Implementation Challenges and Solutions

1. High Initial Investment

The cost of a fully automated system can exceed $500,000. However, manufacturers can offset this through long-term savings in labor costs, reduced scrap rates, and increased production volumes. Government incentives for automation and leasing options also make adoption more accessible.

2. Complex Setup and Programming

Configuring the system for different products requires specialized skills. User-friendly software with pre-built assembly recipes and drag-and-drop interfaces simplifies programming. Additionally, manufacturers offer training programs to help operators quickly learn system operation and maintenance.

3. Compatibility with Existing Infrastructure

Integrating new systems into existing production lines can be challenging. Modular designs and standardized communication protocols (e.g., OPC UA) enable seamless connectivity with other equipment, reducing integration complexity.

Conclusion

Automatic hardware part feeding and assembly systems have emerged as essential enablers of modern manufacturing, delivering unparalleled precision, speed, and flexibility. As industries continue to demand higher quality, faster turnaround times, and cost competitiveness, these systems will become indispensable. By embracing AI, collaborative robotics, and sustainability, automatic assembly technology is not only streamlining production but also paving the way for a future of smart, efficient, and resilient manufacturing.

#automated machinery # Automated part feeding devices # complete feeding systems and components