With the advent of the Industry 4.0 era, the application of automation technology has developed vigorously in the global manufacturing industry, especially in the field of assembly. As core equipment for realizing intelligence and high efficiency in modern production, automatic assembly machines have become an indispensable part of the production process across various industries. By leveraging mechanized operations, intelligent control systems, and sensor technology, these machines automatically assemble parts into finished products, significantly improving production efficiency and product quality while reducing production costs. In this article, we will delve into automatic assembly machines, their advantages, and their impact on the manufacturing industry.

Definition and Working Principle of Automatic Assembly Machines

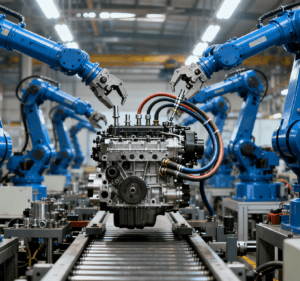

An automatic assembly machine is a machine or system capable of automatically performing the product assembly process. It is typically used to assemble multiple parts into a complete product in accordance with a predefined program and process sequence. The operation of the machine is fully controlled by programs and mainly includes processes such as part feeding, positioning, assembly, fastening, testing, and more. Its core technologies include robotic arms, sensors, PLC (Programmable Logic Controller) control systems, and precision machining equipment.

The working principle of an automatic assembly machine usually consists of the following steps:

Part Feeding and Positioning: The machine feeds the prepared parts to designated positions via an automatic feeding system, and sensors detect whether the parts are correctly positioned. This process ensures that each part is accurately transferred to the next assembly station.

Assembly and Operation: Robotic arms or other automatic assembly tools accurately assemble, connect, or fasten parts in accordance with preset programs. Among these robotic arms, 4-axis robot automatic assembly equipment stands out for its balanced operational flexibility and positioning precision—it can efficiently handle medium-complexity tasks like part rotational fastening and multi-angle alignment, and its compact structure allows seamless integration into existing assembly lines without occupying excessive space, further optimizing the stability of high-precision assembly. High-precision assembly mechanisms are usually used in this process to ensure the assembly quality of each part.

Quality Inspection and Adjustment: After assembly is completed, the machine inspects parameters such as the product’s dimensions and connection firmness. If abnormalities are detected, the machine will automatically make adjustments or reject non-conforming products.

Finished Product Output and Packaging: The assembled products are transferred to the next process (such as testing or packaging) via conveyors or other means.

Advantages of Automatic Assembly Machines

Improved Production Efficiency: One of the main advantages of automatic assembly machines is their ability to significantly boost production efficiency. Traditional manual assembly processes require a large amount of labor and time, while automatic assembly machines can operate continuously 24 hours a day, greatly shortening the product production cycle. For products that require a large number of repetitive operations, automatic assembly machines can complete the assembly of a large number of products in a short period of time.

Reduced Production Costs: The use of automatic assembly machines can effectively reduce reliance on labor, thereby significantly cutting labor costs. As labor costs continue to rise, the application of automatic equipment can help enterprises save substantial funds in long-term operations. In addition, automatic assembly machines can also reduce material waste caused by human errors, improving the utilization rate of raw materials.

Enhanced Product Quality and Consistency: Through precise mechanical operations, automatic assembly machines ensure that each product meets uniform standards during the assembly process, thus guaranteeing consistent product quality. Compared with manual operations, these machines can maintain higher precision and consistency when performing complex assembly tasks, avoiding deviations that may occur in human operations.

Increased Safety: In some hazardous or unsuitable production environments (such as high-temperature, high-pressure, or dangerous chemical environments), automatic assembly machines can replace workers to complete operations, reducing workers’ exposure time to hazardous environments and thereby enhancing production safety.

Flexibility and Scalability: Modern automatic assembly machines offer high flexibility and can be adjusted through simple programming to adapt to the production needs of different products. This means enterprises can produce different types of products through software upgrades or simple hardware modifications without replacing the entire production line, thus improving the utilization rate and flexibility of the production line.

Applications of Automatic Assembly Machines in Various Industries

Automatic assembly machines are widely used across numerous industries, including automotive manufacturing, electronic products, household appliances, medical devices, toys, and more. Specific applications include:

Automotive Manufacturing: In the automotive manufacturing process, automatic assembly machines are mainly used for the automatic assembly of parts and components such as engines, gearboxes, car doors, and instrument panels. Automatic assembly not only improves assembly precision but also reduces manual intervention, enhancing the efficiency and consistency of the production line.

Electronic Product Manufacturing: Electronic products typically have precise and complex structures. Especially for the assembly of small electronic devices such as mobile phones and computers, extremely high precision and operating speed are required. Automatic assembly machines play a significant role in helping enterprises achieve high-precision automated production in these fields.

Household Appliances and Medical Devices: The assembly processes of household appliances (such as washing machines and televisions) rely on automatic equipment to accelerate assembly speed and ensure stable production efficiency. The production of medical devices requires automatic equipment to ensure that each product complies with strict hygiene standards and quality requirements during the production process.

Future Development Trends of Automatic Assembly Machines

With the rapid development of science and technology, automatic assembly machines will become more intelligent, flexible, and eco-friendly in the future. Specific trends include:

Integration of Artificial Intelligence (AI) and Big Data: In the future, automatic assembly machines will use AI technology for autonomous learning and optimization, enabling automatic adjustment of assembly processes based on production data to further improve efficiency and quality. At the same time, through the analysis of big data, enterprises can monitor the operation of production lines in real time and predict equipment failures in advance.

New Modes of Human-Machine Collaboration: In the future, human-machine collaboration modes will become more widespread, where workers and machines will work together to complete more complex assembly tasks. Robots can perform repetitive heavy work, while workers can engage in equipment maintenance, supervision, and complex operations.

Green Manufacturing and Environmental Protection: Green manufacturing will become one of the important trends in automatic assembly machines. Future equipment design will place greater emphasis on energy conservation, emission reduction, and reduced resource consumption to promote sustainable development.

As an important part of modern industry, automatic assembly machines are constantly driving the manufacturing industry toward higher efficiency and intelligence. Through technological innovation and flexible application, automatic assembly machines will provide more competitive production solutions for various industries. In the future, with the advancement of science and technology, automatic assembly machines will demonstrate their great potential in more fields.