In the bustling landscape of manufacturing—where smartphones, cars, medical devices, and household appliances take shape—one piece of equipment stands as the backbone of production: the assembly machine. Far more than a simple “tool,” it is a purpose-built system designed to streamline, standardize, and scale the process of joining individual components into finished products or sub-assemblies. From tiny screws fastening a laptop’s circuit board to heavy robotic arms fitting engine blocks into car chassis, assembly machines bridge the gap between raw parts and market-ready goods, redefining efficiency and precision in modern manufacturing.

At Its Core: What Does an Assembly Machine Do?

At its most basic level, an assembly machine performs controlled, repeatable operations to combine components. Unlike manual assembly—where human workers rely on skill (and are prone to fatigue or error)—assembly machines execute tasks with consistency, speed, and accuracy tailored to the product’s needs. Key functions include:

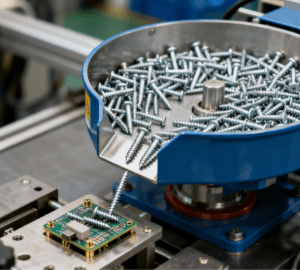

Component Handling: Retrieving, positioning, and feeding parts (e.g., nuts, bolts, microchips) to the assembly station, often via conveyors, robotic grippers, or automated feeders.

For precision components like automotive gear shafts or electronic connector housings—parts that require CNC lathe machining before assembly—the CNC-drejebænk automatisk læsse-/lossesystem serves as a critical link between machining and assembly: it automatically feeds raw materials (e.g., metal rods) into CNC lathes for precision cutting, then transfers the finished parts directly to assembly machine stations (such as robotic grippers or conveyor lines) without human contact. This eliminates precision deviations caused by manual handling (e.g., 0.02mm misalignment from hand-transfer) and ensures a seamless flow of high-quality parts to the assembly line—essential for high-volume production of precision goods like EV transmissions or medical device components.

Joining Operations: Fastening, bonding, or connecting components using methods like screwing, welding, soldering, gluing, or press-fitting.

For example, a small assembly machine might use a torque-controlled screwdriver to attach a phone’s back cover, while a large one uses laser welding to join metal parts in aerospace components.

Quality Checks: Integrating sensors or vision systems to verify assembly correctness—such as ensuring a screw is tightened to the right torque, or a component is aligned within 0.1mm of its target.

Process Integration: Working in tandem with other factory systems (e.g., inventory trackers, conveyor lines, or packaging machines) to create a seamless production flow.

A car assembly line, for instance, uses multiple specialized assembly machines that pass partially built vehicles between stations, each adding a specific part (wheels, seats, electronics) in sequence.

Key Components That Power Assembly Machines

An assembly machine’s capabilities depend on its modular, integrated parts—each serving a unique role in the assembly process. These core components include:

Mechanical Structure: The “body” of the machine, which provides stability and movement. This can range from a compact tabletop frame for small electronics to a large, floor-mounted gantry system for heavy-duty parts. Critical sub-components here include:

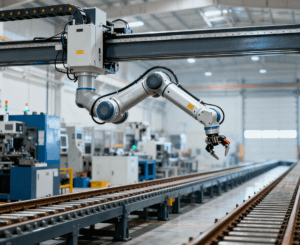

Actuators/Robotic Arms: For precise movement (e.g., a 6-axis robotic arm that rotates and positions parts with micron-level accuracy).

Conveyors/Feeders: To transport parts to and from the assembly zone (e.g., a vibrating feeder that sorts and delivers tiny screws one by one).

Control System: The “brain” that dictates how the machine operates. Most modern assembly machines use a Programmable Logic Controller (PLC)—a digital computer that runs pre-programmed instructions to control movement, timing, and task sequence. Operators interact with the system via a Human-Machine Interface (HMI) (a touchscreen or dashboard) to adjust settings, monitor progress, or troubleshoot issues.

Sensing & Inspection Modules: The “eyes and hands” that ensure quality. These include:

Vision Sensors: Cameras that check for component alignment, missing parts, or surface defects (e.g., detecting a cracked plastic housing before it’s assembled).

Force/Torque Sensors: To measure pressure or tension (e.g., ensuring a bolt is tightened to 5 N·m without stripping the thread).

Power System: The “engine” that supplies energy, typically using electric motors (for precision tasks) or hydraulic/pneumatic systems (for heavy-duty operations like press-fitting metal parts).

Types of Assembly Machines: Tailored to Manufacturing Needs

Assembly machines are not one-size-fits-all—they are designed to match the complexity, volume, and type of product being made. The most common categories include:

Manual-Assist Assembly MachinesIdeal for small-batch production or low-volume, high-variety products (e.g., custom medical devices). These machines reduce manual labor but still require human input: for example, a worker loads components into a fixture, and the machine automatically tightens screws or applies adhesive. They are cost-effective for businesses that don’t need full automation.

Semi-Automatic Assembly MachinesBalance human oversight with automated efficiency, often used in mid-volume production (e.g., small appliance manufacturing). One worker might feed parts into the machine, while the system handles joining and inspection. For instance, a semi-automatic machine for assembling toasters could auto-feed heating elements into the chassis, while a worker positions the outer casing.

Fully Automatic Assembly MachinesOperate with minimal human intervention, designed for high-volume, repetitive production (e.g., smartphone or automotive parts). These machines run 24/7, integrating multiple tasks into one line. A fully automatic EV battery assembly machine, for example, can pick battery cells, stack them into modules, weld connections, and test for defects—all without human hands.

Collaborative Assembly Machines (Cobots)A newer category that works with humans, rather than replacing them. These machines (often robotic arms) are equipped with safety sensors that stop movement if they detect a human nearby, making them ideal for tasks that require both precision and flexibility (e.g., assembling complex electronics or custom furniture). A cobot might assist a worker by holding a heavy component while the human solders a connection, combining the best of human judgment and machine accuracy.

Where Assembly Machines Shine: Key Industry Applications

Assembly machines are ubiquitous across manufacturing, adapting to the unique needs of diverse sectors:

Automotive: Building engines, transmissions, and EV batteries with large, heavy-duty assembly machines that handle metal parts and precise welding.

Electronics: Assembling smartphones, laptops, and IoT devices using compact, high-precision machines that solder microchips, attach screens, and fasten tiny screws.

Medical Devices: Creating syringes, insulin pens, and surgical tools with sterile assembly machines that meet strict regulatory standards (e.g., using cleanroom-compatible materials and real-time defect detection).

Household Appliances: Producing washers, dryers, and refrigerators with semi-automatic or fully automatic machines that attach motors, seal doors, and test functionality.

The Future of Assembly Machines: Smarter, More Flexible

As manufacturing evolves toward “Industry 4.0”—the era of smart, connected factories—assembly machines are becoming more advanced than ever. Key trends include:

IoT Integration: Sensors in assembly machines collect real-time data (e.g., temperature, vibration, cycle time) and send it to cloud platforms for monitoring. This allows predictive maintenance (e.g., alerting technicians to a worn part before it causes a breakdown) and process optimization (e.g., adjusting speed to reduce energy use).

AI-Powered Optimization: Artificial intelligence analyzes production data to fine-tune operations—for example, an AI system might adjust a machine’s torque settings if it detects a pattern of loose screws, improving quality without human intervention.

Digital Twins: Virtual replicas of assembly machines let manufacturers test new processes or troubleshoot issues in a digital space before applying changes to the physical machine. This reduces downtime and lowers the risk of errors when launching new products.

Flexible Automation: Modular assembly machines that can be reconfigured quickly for different products—critical as consumer demand shifts toward “small-batch, personalized” goods. A single machine might assemble both wireless earbuds and smartwatches by swapping out fixtures and updating its PLC program.

Why Assembly Machines Matter

In a world where consumers expect faster delivery, higher quality, and lower prices, assembly machines are not just “nice to have”—they are essential. They eliminate the inconsistencies of manual labor, cut production time, reduce waste (by catching defects early), and let manufacturers scale operations to meet demand. For workers, they take over repetitive, physically demanding tasks (e.g., lifting heavy parts or tightening hundreds of screws a day), freeing humans to focus on higher-value work like design, maintenance, and innovation.

At its heart, an assembly machine is more than metal and code—it is a catalyst for progress. It turns ideas into products, raw materials into essentials, and small workshops into global manufacturers. Whether it’s a tiny tabletop screwdriver or a massive robotic assembly line, it embodies the core of manufacturing: turning complexity into simplicity, and possibility into reality.

Artificial Intelligence Five-sided Automatic Assembly Machine

Optimization of the five-sided automatic assembly machine by AI