Industry Trend: Shifting to Quality-Oriented with Core Tech Directions Defined

At the critical stage when the food industry is shifting from scale expansion to quality improvement, high-end equipment has become an important driver for industrial upgrading. A recent annual promotion meeting for the National Key R&D Program showcased China’s latest progress in high-tech food processing equipment, and also outlined the technological blueprint for the next generation of food processing equipment for the industry. According to information released at the meeting, a number of cutting-edge technologies centered on non-thermal processing and intelligent sensing are moving from laboratory to engineering applications, becoming key variables driving industry transformation.

Core Tech 1: Non-Thermal Processing Breaks Through Traditional Limitations

For a long time, traditional food processing has been highly dependent on thermal processing technologies. While ensuring food safety, it inevitably leads to problems such as nutrient loss, flavor changes and relatively high energy consumption. To address these industry pain points, the R&D direction of new-generation food processing equipment is clearly shifting toward low-temperature, non-thermal and precision processing. Non-thermal sterilization technologies such as ultra-high pressure, ultrasound and plasma are regarded as important pillars for breaking through traditional processing paths. These technologies achieve microbial inactivation through physical effects, maximizing the retention of the natural quality of food without relying on high temperatures, thus providing a new industrial solution for high-quality, low-additive food products.

From the equipment perspective, non-thermal processing is not only a process innovation, but also puts forward higher requirements for key components, system integration and safety control. How to achieve stable, controllable and reproducible engineering operation is the core of whether the technology can be truly applied. The phased results presented at the promotion meeting show that relevant research is no longer limited to principle verification, but has begun to extend to complete sets of equipment and application scenarios. This change means that non-thermal processing technology is gradually meeting the basic conditions for large-scale application, and its industrialization prospects are becoming increasingly clear.

Core Tech 2: Intelligent Upgrading & Industrial Development Outlook

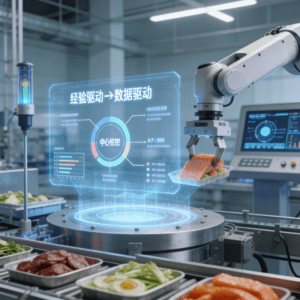

Parallel to the advancement of non-thermal processing is the intelligent upgrading of food processing processes. With the tightening of food safety supervision and the improvement of quality requirements, relying solely on manual experience and post-processing testing has been difficult to meet practical needs. Intelligent detection and monitoring technologies are being systematically integrated into processing equipment, enabling real-time control of key indicators through online sensing, data analysis and intelligent judgment. This not only helps improve product consistency and safety levels, but also provides technical support for the transformation of food processing from experience-driven to data-driven.

It is worth noting that such intelligent technologies do not exist in isolation, but are deeply integrated with processing equipment to become part of the system’s capabilities. Specifically, the integration of Automatisk tilførsel og montering af hardwaredele systems into food processing equipment has significantly enhanced automation levels—these systems realize precise and efficient automatic feeding and assembly of key hardware components such as processing molds and transmission parts, reducing manual intervention errors while improving production continuity. Equipment is no longer just “hardware” that executes processing operations; it is gradually equipped with sensing, judgment and feedback capabilities to participate in production decision-making. This not only improves the automation and flexibility of food production, but also lays the foundation for the future production mode of multi-variety and small-batch manufacturing.

From a more macro perspective, continuous national investment and systematic layout have provided important guarantees for the leapfrog development of food processing equipment. Through collaborative research among industry, academia and research institutions to focus on breakthroughs in common key technologies, it helps avoid redundant R&D and resource fragmentation, and accelerates the formation of a core technology system with independent intellectual property rights. This is of long-term significance for improving the overall level of China’s food equipment industry and enhancing the security of the industrial chain.

It can be predicted that as these “cutting-edge technologies” gradually mature and enter the application stage, the technological structure and competition logic of the food machinery industry will also change accordingly. Future competition will be reflected not only in manufacturing capabilities, but also in the depth of understanding of new processes, the ability to control system integration and the speed of response to the needs of the food industry. Non-thermal processing and intelligent detection are the key to opening up this new situation.

From the discussions at an annual promotion meeting, a signal can be detected: the next generation of food processing equipment is accelerating its evolution toward safer, smarter and greener development. This is not only a result of technological progress, but also a choice for the high-quality development of the food industry. For the industry, this is both a challenge and a rare historical opportunity.