In modern bathroom products, the toilet flush valve is a core component that determines the user experience and water-saving performance. This seemingly simple device needs to accurately integrate more than ten parts such as the valve body, valve core, sealing ring, and button assembly. Its assembly precision directly affects the flushing force, sealing performance, and service life. The emergence of the Toilet Flush Valve Assembly Machine has completely changed the situation of low efficiency and poor consistency in traditional manual assembly, injecting new momentum of “exquisite manufacturing” into the bathroom industry with automation and intelligent technologies.

Solving Assembly Pain Points: From “Manual Work” to “Millimeter-Level Control”

The assembly of traditional toilet flush valves has long relied on manual work, facing three core problems: First, leakage caused by incorrect installation of the sealing ring – uneven force during manual press-fitting easily leads to offset or deformation of the sealing ring, and about 10% of finished products have potential water leakage risks; Second, insufficient concentricity between the valve core and the valve body, resulting in jamming or unstable water flow during flushing; Third, large parameter dispersion in mass production, with the service life of products in the same batch differing by 3-5 years.

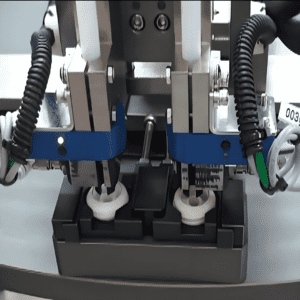

The Toilet Flush Valve Assembly Machine overcomes these pain points through a systematic technical solution. Its 3D visual positioning system can identify the tiny positioning grooves inside the valve body and the assembly reference points of the valve core, controlling the concentricity between them within 0.05mm to ensure smooth and unobstructed water flow channels; The multi-station collaborative robotic arm operates step by step according to the process of “valve body feeding → pre-installation of sealing ring → precise pressing → valve core embedding → docking of button assembly”, with the action error of each station not exceeding 0.1mm; The pressure closed-loop control system automatically adjusts the pressure (adjustable from 5-20N) according to different materials (silicone, EPDM) when press-fitting the sealing ring, ensuring tight sealing while avoiding accelerated aging caused by excessive extrusion.

Technical Architecture: Four Systems Supporting “Full-Process Precision Assembly”

The efficient operation of the Toilet Flush Valve Assembly Machine relies on the collaborative cooperation of four core systems, forming a complete closed loop from part recognition to finished product inspection:

Flexible feeding system: Adopts differentiated feeding methods for parts of different shapes (such as cylindrical valve cores, sheet buttons, and annular sealing rings) – vibrating plates screen and arrange valve bodies in a directional manner, vacuum suction cups grab easily deformable sealing rings, and belt lines convey button assemblies with holes, ensuring that parts enter the assembly process in a unified posture, with a feeding accuracy of 99.9%.

Intelligent assembly execution system: Composed of a 6-axis collaborative robot and special tooling, it can complete various operations such as screw tightening, press-fitting, and plugging. For example, when installing the valve core drive rod, the robot first controls the screw tightening force through a torque sensor (within the range of ±5% of the preset value), and then confirms the insertion depth through a displacement sensor to avoid jamming caused by over-tightening or falling off caused by over-loosening.

Online detection system: After assembly, the equipment automatically conducts two key tests – air pressure tightness detection injects 0.3MPa air pressure into the valve body, maintains the pressure for 3 seconds, and if the pressure drop exceeds 0.01MPa, it is judged as unqualified; The simulated flushing test injects a fixed amount of clean water through a water pump to detect the drainage time and residual water volume, ensuring compliance with national water-saving standards (single flushing volume ≤5L).

Data traceability system: Each finished product corresponds to a unique QR code, recording 18 parameters such as pressure, torque, and concentricity during the assembly process, which can be traced to specific batches, equipment, and operation periods through the MES system, providing data support for quality analysis and process optimization.

Scenario Implementation: “Flexible Intelligent Manufacturing” Adapting to Diverse Needs

Different types of toilet flush valves (such as direct flush, siphonic, and intelligent sensor types) have structural differences. The Toilet Flush Valve Assembly Machine realizes the flexible production capability of “one machine for multiple uses” through modular design.

In the production of ordinary household flush valves, the equipment focuses on “high speed and stability”, capable of assembling 300-400 pieces per hour, which is 5 times more efficient than manual work, and the defect rate is reduced to below 0.5%; For electronic flush valves of intelligent toilets, the “precision mode” is activated, focusing on controlling the docking accuracy between electromagnetic components and mechanical structures to ensure no delay in induction signals and a flushing response time error ≤0.2 seconds; For large-diameter flush valves used in engineering, the equipment can be equipped with extended robotic arms and high-torque actuators to adapt to the assembly of valve bodies with a diameter of more than 100mm, meeting the large flow demand of public toilets.

After introducing this equipment, a bathroom enterprise not only reduced the number of workers in the flush valve production line from 12 to 2 (only responsible for monitoring and material replenishment) but also discovered quality fluctuations caused by “differences in the hardness of sealing ring batches” through data traceability, prompting upstream suppliers to improve the material formula, extending the average service life of products from 5 years to 8 years.

Industry Value: From “Product Upgrade” to “Ecological Reconstruction”

The application of the Toilet Flush Valve Assembly Machine is reshaping the competitive landscape of the bathroom manufacturing industry. For enterprises, it is not only an upgrade of production tools but also brings three in-depth values:

Cost optimization: Calculated based on an annual output of 1 million flush valves, the equipment can save about 3 million yuan in labor costs per year, and reduce rework losses by 1.5 million yuan per year due to the decrease in defect rates. The investment payback period is usually 1.5-2 years.

Standard output: By unifying assembly parameters, it promotes the industry to shift from “experience dependence” to “data-driven”, helping enterprises to meet international standards such as water-saving certification and mute standards faster, and enhancing export competitiveness.

Innovation empowerment: A large amount of assembly data accumulated by the equipment (such as the optimal matching parameters of parts of different materials) can provide references for new product research and development. For example, by analyzing the relationship between the compression amount of the sealing ring and its service life, it can guide the design of better sealing structures.

With the upgrading of consumers’ demands for “durability” and “intelligence” of bathroom products, the Toilet Flush Valve Assembly Machine is extending from “backend assembly equipment” to the front-end R&D link – by simulating product performance under different assembly parameters, it assists engineers in optimizing design schemes, realizing full-chain collaboration of “design – manufacturing – detection”. In this transformation of “bathroom intelligent manufacturing”, such precision equipment focusing on core components is becoming the key confidence for enterprises to seize the high-end market.