In the wave of global (intelligent manufacturing), the “last mile” of hardware part processing—feeding and assembly—has long been a bottleneck restricting production efficiency. Traditional manual operations, relying on workers’ experience to sort, position, and assemble screws, nuts, bearings, and other hardware parts, are not only limited by low efficiency (an average worker can complete only 30-50 simple assembly tasks per minute) but also prone to errors caused by fatigue, leading to a product defect rate of up to 5-8%. With the advent of Industry 4.0, Automatic Hardware Part Feeding And Assembly systems have emerged as a key solution to break this bottleneck. By integrating precision machinery, machine vision, and robotic technology, they realize the full-process automation of “part sorting → accurate positioning → intelligent assembly → real-time inspection,” becoming an indispensable core link in high-efficiency, high-quality, and low-cost production for industries such as automotive, electronics, and medical devices.

The Core Technology System of Automatic Hardware Part Feeding And Assembly

The realization of automatic hardware part feeding and assembly does not rely on a single device but on the collaborative operation of a multi-technology integration system. Its core can be divided into two major modules: automatic feeding (solving the problem of “how to stably and accurately supply parts”) and automatic assembly (solving the problem of “how to precisely assemble parts to target positions”), with machine vision and data communication serving as the “neural network” connecting the two modules.

- Automatic Feeding: From “Rigid Sorting” to “Flexible Adaptation”

The feeding link is the foundation of automatic assembly—only when parts are stably sorted, oriented, and transported can subsequent assembly operations be carried out smoothly. In response to the diverse characteristics of hardware parts (such as cylindrical screws, irregular(buckles), and thin-walled bearings), the industry has developed three mainstream feeding technologies:

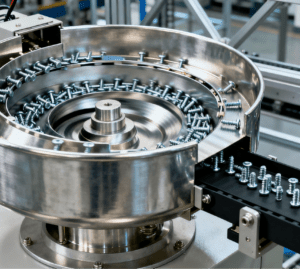

Vibratory Bowl Feeders: The “Workhorse” for Standard PartsAs the most mature and widely used feeding equipment, vibratory bowl feeders rely on the high-frequency vibration of the bowl body to drive parts to move along a spiral track. Through structural designs such as guide rails, baffles, and orientation grooves on the track, parts are automatically adjusted to a unified posture (e.g., screws with heads facing up, bearings with inner rings facing outward) during movement. For standard hardware parts such as M3-M8 screws or φ5-φ20mm washers, vibratory bowl feeders can achieve a feeding efficiency of 120-180 pieces per minute, with a posture accuracy of over 99.5%. Their advantages lie in low cost and high stability, making them the first choice for mass production scenarios (e.g., automotive bolt assembly lines).

Flexible Feeding Systems: Breaking the “Shape Limitation” of PartsFor non-standard or irregular hardware parts (such as 异形 fasteners, curved brackets, or thin-walled sleeves), traditional vibratory bowls often face problems such as stuck parts or low orientation accuracy. Flexible feeding systems, which combine “visual recognition + robotic sorting,” have become a new solution. The system uses a flat vibrating plate to disperse parts in a disorderly manner, and a 2D/3D industrial camera (with a resolution of up to 5 million pixels) captures the position and posture of each part in real time. After AI algorithm analysis, a collaborative robot or SCARA robot with a flexible gripper (made of food-grade silicone or rubber) is instructed to pick up parts and place them in the correct orientation on the conveyor belt. Taking the feeding of automotive engine valve collets as an example, a flexible feeding system can achieve a sorting efficiency of 60-80 pieces per minute, with an error rate of less than 0.3%, completely solving the problem of difficult feeding of irregular parts.

Magnetic Conveyor Feeding: Targeting Ferromagnetic PartsFor ferromagnetic hardware parts (such as steel bolts, iron nuts, or magnetic bearings), magnetic conveyor feeding systems use permanent magnets or electromagnetic rails to(adsorb) parts to the conveyor surface, ensuring stable transportation even at inclined angles (up to 30°). This technology is particularly suitable for assembly lines with limited space, as it can realize “vertical feeding” or “curved transportation” without worrying about parts falling. In the assembly of refrigerator compressors, magnetic conveyors can stably transport φ8mm magnetic bearing sleeves at a speed of 100 pieces per minute, reducing the floor space of the feeding system by 40% compared with traditional conveyors.

- Automatic Assembly: Precision Control and Quality Assurance

After parts are stably fed, the automatic assembly link needs to complete the “final step” of combining parts with the target workpiece—this process requires not only high positioning accuracy but also real-time control of assembly force to avoid damaging parts or workpieces. The core technologies here include:

Robotic Assembly: Matching Different Precision RequirementsDifferent hardware assembly scenarios have very different requirements for robot types. For example:

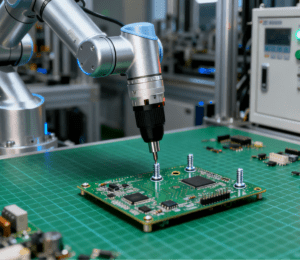

SCARA Robots: With high-speed horizontal movement capabilities (maximum speed up to 5m/s) and repeated positioning accuracy of ±0.01mm, they are suitable for small hardware assembly in the electronics industry, such as assembling connectors on smartphone motherboards or screws on laptop casings. A SCARA robot can complete 80-100 screw tightening operations per minute, which is 3-4 times the efficiency of manual work.

Six-Axis Robots: With flexible multi-angle movement capabilities, they are suitable for complex assembly tasks, such as installing bearings on automotive gearboxes or assembling multi-directional fasteners on medical devices. Equipped with force sensors, six-axis robots can adjust the assembly angle in real time according to the contact force between parts, ensuring that the coaxiality error of bearing assembly is less than 0.05mm.

Collaborative Robots: With safety sensors and human-machine collaboration functions, they are suitable for small-batch, multi-variety assembly scenarios (such as customized hardware processing). Workers can work side by side with collaborative robots—when a worker approaches, the robot automatically reduces its speed; when the worker leaves, it resumes normal operation. This not only improves efficiency but also ensures operational safety.

Force Control Technology: The “Soft Protection” for AssemblyFor hardware parts that are easily damaged (such as plastic buckles, thin-walled nuts, or precision gears), excessive assembly force can lead to cracks or deformation. Force control technology solves this problem by installing a six-dimensional force sensor at the end of the robot. During assembly, the sensor monitors the contact force between the part and the workpiece in real time (detection accuracy up to 0.1N) and feeds back data to the control system. When the force exceeds the preset threshold (e.g., 5N for plastic buckles), the system automatically reduces the assembly speed or adjusts the direction until the force returns to the safe range. In the assembly of smartwatch middle frames, force control technology reduces the damage rate of plastic buckles from 12% (manual assembly) to less than 0.5%.

Online Inspection: Real-Time Elimination of DefectsAutomatic assembly does not mean “no supervision”—online inspection technology ensures that every assembled product meets quality standards. Common inspection methods include:

Visual Inspection: Using industrial cameras to check whether parts are missing (e.g., whether a screw is forgotten to be installed), offset (e.g., whether a buckle is assembled in place), or damaged (e.g., whether a nut has a thread defect). The inspection speed can reach 100 pieces per minute, with a recognition accuracy of over 99.8%.

Dimensional Inspection: Using laser measuring instruments to detect the assembly dimensional accuracy (e.g., the distance between two bolts, the coaxiality of bearings). In the assembly of automotive brake calipers, laser measuring instruments can detect the assembly error of brake pad pins in 0.5 seconds, ensuring that the error is within ±0.03mm.

Functional Inspection: For assembled components (e.g., a bolted connection), functional tests such as torque detection (whether the bolt torque meets the standard) or pressure resistance (whether the assembled part can withstand a certain pressure) are carried out. Torque sensors with an accuracy of ±0.1N·m are widely used in this link to ensure that the bolt torque meets the design requirements (e.g., 8N·m for automotive chassis bolts).

Multi-Industry Application: How Automatic Feeding And Assembly Reshapes Production

Automatic hardware part feeding and assembly systems are not “one-size-fits-all”—they adapt to the unique needs of different industries and solve industry-specific pain points.

- Automotive Manufacturing: High Beat, High Precision

The automotive industry has the highest requirements for assembly efficiency and precision—an automotive assembly line needs to complete the assembly of thousands of hardware parts (bolts, nuts, bearings, etc.) per hour, and any error may affect driving safety. Automatic feeding and assembly systems have become the core of automotive smart workshops:

In the assembly of automotive engines, a rotary automatic assembly machine integrates 6 vibratory bowl feeders (supplying different specifications of bolts) and 4 SCARA robots. The robots complete bolt feeding, positioning, and tightening in sequence, with a beat time of only 8 seconds per engine, and the bolt torque accuracy reaches ±2%.

In the assembly of automotive door hinges, a six-axis robot with force control technology assembles the hinge shaft and bearing. The force sensor monitors the assembly force in real time, ensuring that the hinge rotation is smooth without jamming, and the qualification rate of finished products reaches 99.9%.

- Electronic and Electrical Industry: Miniaturization, High Density

With the miniaturization of electronic products (such as smartphones, tablets, and smart wearables), hardware parts are becoming smaller and more densely arranged—some screws have a diameter of only 1.5mm, and the assembly error tolerance is less than 0.02mm. Automatic feeding and assembly systems solve the problem of “difficult assembly of micro parts”:

In the assembly of smartphone motherboards, a flexible feeding system uses a 3D vision camera to identify φ1.5mm micro screws, and a SCARA robot with a micro gripper (jaw opening of 0.5mm) picks up the screws and tightens them to the motherboard. The assembly speed is 50 screws per minute, and the positioning accuracy is ±0.01mm, which is far beyond the manual operation limit.

In the assembly of LED bulbs, an automatic assembly line uses magnetic conveyors to feed φ3mm metal lamp caps, and a collaborative robot assembles the lamp cap with the bulb housing. The line can produce 1,200 LED bulbs per hour, and the defect rate is reduced from 3% (manual) to 0.2%.

- Medical Device Industry: High Cleanliness, High Reliability

Medical devices (such as surgical instruments, infusion pumps, and diagnostic equipment) have strict requirements for assembly cleanliness and reliability—parts cannot be contaminated by human hands, and assembly errors may affect patient safety. Automatic feeding and assembly systems in clean rooms (Class 100,000) have become the standard configuration:

In the assembly of surgical hemostats, a fully enclosed automatic feeding system uses sterile conveyors to transport stainless steel clips, and a six-axis robot with a sterile gripper assembles the clips with the hemostat body. The entire process is free of manual contact, and the bacterial contamination rate is less than 0.01%.

In the assembly of infusion pumps, an online laser measuring instrument detects the assembly gap between the pump core and the shell in real time, ensuring that the gap is between 0.05-0.1mm, which avoids liquid leakage during infusion.

Advantages, Challenges, and Future Trends

- Core Advantages: Beyond Manual Operation

Compared with traditional manual assembly, automatic hardware part feeding and assembly systems have obvious advantages:

Efficiency Leap: The assembly efficiency is 3-10 times that of manual work. For example, an automatic screw assembly line can complete 1,000 screw tightening operations per hour, while a worker can only complete 150-200.

Precision Improvement: The assembly error is reduced from 0.1-0.5mm (manual) to 0.01-0.05mm, which is crucial for high-precision products such as automotive parts and medical devices.

Cost Optimization: Although the initial investment is high (a set of medium-sized automatic assembly lines costs 500,000-2 million yuan), it can save 2-3 manual labor costs per year. Generally, the investment can be recovered within 2-3 years.

Quality Stability: The defect rate is reduced from 5-8% (manual) to less than 1%, and each assembly process has data records, which is convenient for traceability and quality management.

- Current Challenges: Breaking the “Application Barriers”

Despite its advantages, automatic hardware part feeding and assembly still faces some challenges in popularization:

Multi-Variety Compatibility: For small-batch, multi-variety production (e.g., customized hardware), the replacement of feeding and assembly equipment (such as changing vibratory bowl tracks or adjusting robot programs) takes a long time (2-4 hours), which affects production efficiency.

Complex Parts Handling: For parts with special shapes (e.g., non-symmetrical brackets) or soft materials (e.g., plastic gaskets), the feeding stability and assembly accuracy are still difficult to guarantee, and the error rate may reach 2-3%.

High Initial Investment: Small and medium-sized enterprises (SMEs) often hesitate to invest due to the high cost of automatic systems, which restricts the popularization of the technology in the SME sector.

- Future Trends: Towards “Intelligent and Flexible”

With the development of AI, digital twin, and other technologies, automatic hardware part feeding and assembly will move towards a more intelligent and flexible direction:

AI-Driven Intelligent Optimization: AI algorithms will be used to optimize the feeding speed and assembly path in real time. For example, according to the wear degree of the vibratory bowl, the AI system automatically adjusts the vibration frequency to maintain stable feeding; according to the assembly error data, it optimizes the robot’s movement trajectory to reduce errors.

Digital Twin Virtual Debugging: Before the actual operation of the automatic system, a digital twin model of the feeding and assembly line is established in the virtual environment. Through virtual debugging, the problems of equipment collision or program errors are found in advance, reducing the on-site debugging time by 50% or more.

Modular and Rapid Changeover: Modular design of feeding and assembly equipment (e.g., quick-change vibratory bowls, interchangeable robot grippers) will shorten the changeover time between different parts to 15-30 minutes, meeting the needs of small-batch, multi-variety production.

Green and Low-Energy Consumption: The development of low-energy consumption equipment (e.g., energy-saving vibratory bowls, high-efficiency motors) will reduce the energy consumption of automatic systems by 20-30%, in line with the global trend of green manufacturing.

Conclusion

Automatic Hardware Part Feeding And Assembly is not just a simple combination of “machines replacing humans”—it represents the transformation of manufacturing from “experience-driven” to “data-driven” and from “low-efficiency manual” to “high-precision intelligent.” In the future, with the continuous integration of new technologies such as AI and digital twin, this system will become more flexible, intelligent, and low-cost, not only helping large enterprises improve production efficiency but also enabling small and medium-sized enterprises to embrace intelligent manufacturing. For the global manufacturing industry, automatic hardware part feeding and assembly is not only a “tool for efficiency improvement” but also a “key 拼图 (puzzle piece)” to achieve Industry 4.0 and build a smart factory.