During the “14th Five-Year Plan” period, China’s foundry industry took solid strides on the path of high-quality development, laying a robust foundation for supporting the transformation of the equipment manufacturing industry from large to strong. Faced with a complex external environment, the foundry industry demonstrated strong resilience: it maintained the world’s top position in industrial scale, continuously optimized its industrial structure, achieved major breakthroughs in technological innovation, realized independent manufacturing of castings in key fields, solved multiple “bottleneck” problems, significantly improved the manufacturing level of foundry equipment, and delivered remarkable results in green transformation. Looking ahead to the “15th Five-Year Plan” period, the foundry industry will further deepen innovation-driven development, promote the all-round empowerment of digital-intelligent and green technologies, continuously enhance the resilience and security of the industrial chain and supply chain, and provide important support and basic guarantee for the innovative development of the equipment manufacturing industry.

Achievements of the Foundry Industry During the “14th Five-Year Plan” Period

Guided by national strategies and driven by market demand, the foundry industry unswervingly pursued high-quality development during the “14th Five-Year Plan” period. It achieved a series of remarkable accomplishments in stabilizing scale, optimizing structure, strengthening innovation, promoting green development, and enabling intelligence, laying a solid foundation for supporting the security and stability of the industrial chain and supply chain of China’s equipment manufacturing industry.

Steady Growth in Industry Scale and More Rational Industrial Structure and Layout

During the “14th Five-Year Plan” period, China’s total casting output remained the world’s highest, and the industry underwent a strategic shift from pursuing “quantitative growth” to focusing on “qualitative improvement”. While maintaining scale advantages, the industrial structure was adjusted at an accelerated pace: the proportion of aluminum (magnesium) alloy castings increased significantly, supporting the lightweight development trends in new energy vehicles, aerospace, industrial robots and other fields; the proportion of high-value-added products such as ductile (vermicular) iron castings approached 30%, and the quality and efficiency of enterprises continued to improve.

In terms of spatial layout, a foundry industrial layout coordinated with major national equipment manufacturing bases such as the Beijing-Tianjin-Hebei, Yangtze River Delta, Pearl River Delta, and Chengdu-Chongqing regions was formed. Weifang, Chongqing, Ningbo, Wuhu, Ma’anshan, Botou and other cities developed distinctive foundry industry cluster (park) models, resulting in a more rational industrial layout and increasingly prominent cluster effects.

Abundant Achievements in Technological Innovation and Accelerated Cultivation of New Productive Forces

During the “14th Five-Year Plan” period, the foundry industry made a series of breakthroughs in new materials, new processes and major equipment, further improved basic manufacturing capabilities, and accelerated the formation of new productive forces.

In the field of new materials, the mass application of new materials such as nitrogen-containing gray cast iron, low-temperature high-toughness ductile iron, thick-section silicon-solution-strengthened ductile iron, and austempered ductile iron (ADI) has greatly improved the comprehensive performance of basic components; cast steel materials with high temperature resistance, corrosion resistance, low temperature resistance and wear resistance have become increasingly mature, breaking through multiple “bottleneck” technical problems; in the field of light alloys, heat-treatment-free aluminum alloys, high-strength magnesium alloys, titanium alloys and superalloys have provided key material support for high-end fields such as new energy vehicles, aerospace, and national defense and military industry.

In the field of casting manufacturing, significant breakthroughs have been achieved in numerous areas, including high-carbon-equivalent high-strength low-stress machine tool castings, 26MW offshore wind power low-temperature ductile iron castings, QT1000-5 ultra-high-strength ductile iron crankshafts, 100-ton-level nuclear spent fuel transport containers, 40MPa high-pressure hydraulic valve bodies, H-class heavy-duty gas turbine exhaust casings, key castings for 630-650℃ ultra-supercritical units, ultra-large stainless steel runners for 1 million kilowatt hydropower units, large integrated die-cast rear floors, front floors and battery trays for new energy passenger vehicles, single-crystal and directionally solidified aero-engine blades, turbine blades for F-class and above heavy-duty gas turbines, and large complex thin-walled magnesium alloy and titanium alloy casings.

The localization level of foundry equipment has reached a new height. Major breakthroughs have been made in 16,000-ton ultra-large die-casting machines, 7,000-ton magnesium alloy double-shot molding machines, 2000L large-scale core making machines, 3m large-diameter centrifuges, high-power IGBT medium-frequency induction melting furnaces, 3T vacuum consumable skull furnaces, 100kg (titanium-based) vacuum suspension melting furnaces, and large-scale 3D printing equipment. A large number of high-end equipment such as high-efficiency automatic molding lines, automatic pouring robots, online testing instruments, and intelligent grinding units have been successfully developed domestically and put into use, laying a hardware foundation for intelligent manufacturing.

New Stage in Green and Low-Carbon Development and Enhanced Sustainable Development Capacity

During the “14th Five-Year Plan” period, the overall level of green and low-carbon development in the industry achieved a leap forward. The official implementation of the Emission Standard of Air Pollutants for Foundry Industry has drawn a clear environmental red line for the industry: 23,000 enterprises have obtained foundry industry pollutant discharge permits, and 103 enterprises have been rated as Class A enterprises in environmental performance grading management.

Remarkable results have been achieved in the coordinated improvement of pollution reduction and carbon reduction. A large number of enterprises have established energy management systems, and distributed photovoltaic green power has been applied in factories; energy-saving technologies such as short-process casting, near-net shape forming processes, and waste heat recovery have been widely used; the recycling volume of foundry waste sand has increased from 4 million tons to 8 million tons; synthetic cast iron technology has significantly improved the utilization rate of scrap steel; the proportion of recycled aluminum in raw materials has continued to increase; and foundry aluminum alloy and options have been officially listed for trading. A circular economy model has been gradually established, and green development has become a distinctive feature of the high-quality development of the foundry industry.

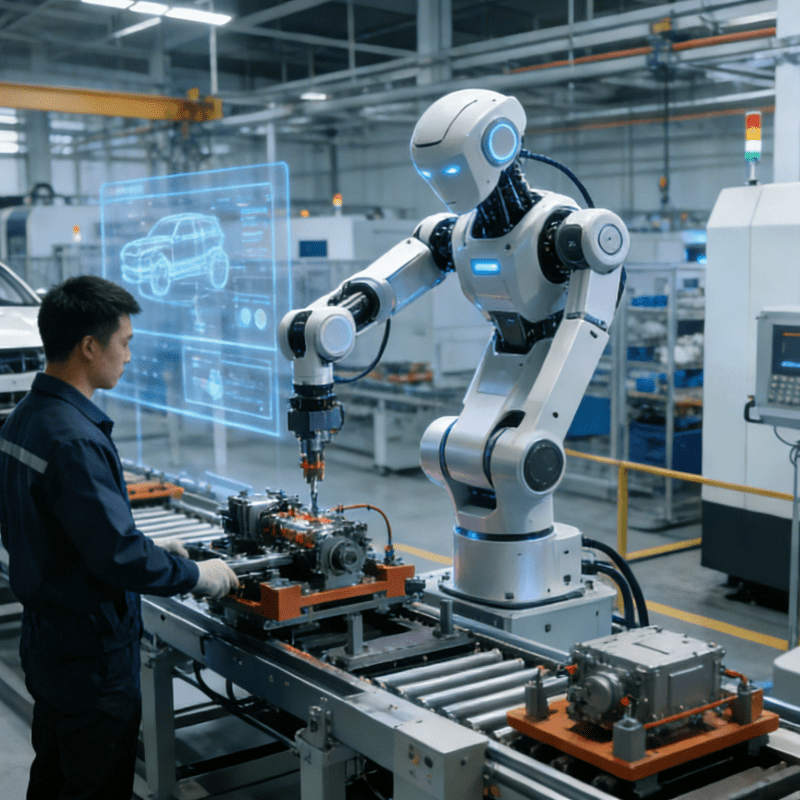

Significant Empowerment of Digital-Intelligent Technologies and Rapid Improvement in Intelligence Level

The level of integrated application of intelligent equipment and systems has been greatly improved. Fully automated production lines, automatic pouring robots, large die-casting units, 3D sand mold printers, intelligent grinding robots, robotic small product tray loading systems, and intelligent warehousing and logistics systems have been applied in large-scale production—among them, the robotic small product tray loading systems have effectively improved the automation level of the sorting, loading and storage links of small castings, reducing manual intervention and ensuring the consistency and efficiency of the post-processing process; multiple intelligent manufacturing service providers have emerged in the industry to provide mature solutions. Through the integration of general industrial software, special software such as full-process virtual casting production execution systems, intelligent equipment remote operation and maintenance platforms, as well as management and control platforms and production operation management systems for different segments, have basically achieved full coverage of intelligent manufacturing software solutions for foundry enterprises. During the “14th Five-Year Plan” period, two enterprises were rated as Intelligent Manufacturing Demonstration Factories by the Ministry of Industry and Information Technology, three enterprises were rated for Excellent Intelligent Manufacturing Scenarios, two projects were rated as Innovative Leading Application Cases of Industrial Internet Platforms, and one enterprise was rated as a “Lighthouse Factory” by the World Economic Forum.

New Progress in Service-Oriented Manufacturing and International Operations

Transformation from “production-oriented” to “service-oriented” manufacturing. A number of 3D printing service centers have been built successively, providing not only sand mold printing but also product design services based on digital simulation of additive manufacturing; some foundry enterprises have actively participated in the front-end design and R&D of products by main engine manufacturers, especially in the lightweight of components and the development and trial production of integrated castings; foundry equipment enterprises provide remote operation and maintenance services, greatly shortening the time for equipment maintenance and fault diagnosis; laboratories of many large enterprises have passed CNAS certification and provide testing and certification services. In addition, the platform manufacturing service capabilities and supporting roles of 3D printing centers, mold centers, heat treatment centers, electroplating and waste sand treatment centers built in industrial clusters have been continuously improved.

International layout has evolved from “product export” to “capacity export”. To respond to changes in the global trade pattern and build a more stable and efficient global supply chain system, many enterprises have integrated international resources and built stable and efficient international supply chain systems through overseas investment and factory construction, mergers and acquisitions, and technological cooperation.

Opportunities and Challenges Facing Industry Development

During the “14th Five-Year Plan” period, China’s foundry industry successfully completed the main tasks proposed in the “14th Five-Year Plan” development plan. However, facing the profound changes brought about by the new round of industrial revolution and the huge challenges brought by the uncertainty of the global political and economic situation, the industry still has problems such as low industrial concentration, weak basic manufacturing capacity of high-end castings, shortcomings in the resilience of the industrial chain and supply chain, and unbalanced levels of green and low-carbon development. The task of high-quality development of the industry remains arduous.

Under the new development pattern of domestic and international “dual circulation”, the foundry industry faces both opportunities and challenges. During the “15th Five-Year Plan” period, enterprises should pay more attention to the changing trends of both domestic and foreign casting markets, continuously strengthen technological innovation, accelerate the pace of transformation and upgrading, and improve the resilience and security level of the domestic industrial chain and supply chain. Centering on “bringing in” and “going global”, they should integrate international resources, optimize the global industrial layout, and expand the international market share of high-end castings.

From the perspective of domestic situation and development trends, the development and research of new material technologies, new process technologies and high-end equipment have brought new momentum to the foundry industry; digitalization, intelligence and green low-carbon technologies will empower the high-quality development of enterprises. Under the background of new-type industrialization, the national key implementation of the “Two Priorities”, “Two New Initiatives”, “Two Industries” projects, as well as the layout and development of eight emerging industries and nine future industries, will not only promote the transformation and development of the foundry industry but also bring new casting market demand. The “15th Five-Year Plan” period is a crucial decisive period for China to achieve the goals of carbon peaking and carbon neutrality. Opportunities and challenges coexist in green and low-carbon development. The foundry industry will continue to develop towards “higher quality”, “greener” and “more innovative”, while a number of small and medium-sized enterprises may be eliminated by the market due to the pressure of transformation costs, and the industrial concentration will be further improved.

From the perspective of international situation and development trends, the countercurrent of economic globalization has accelerated the restructuring of the global foundry industry pattern. The promotion of “reindustrialization” by developed countries and the undertaking of international industrial transfer by emerging economies will have a certain impact on China’s foundry industrial chain and supply chain. However, China has prominent advantages in the complete foundry industrial chain, with obvious advantages in casting quality, labor productivity and cost, and will remain an important position in the global industrial pattern for a long time. The so-called “reciprocal tariffs” unilaterally proposed by the United States have a huge impact on the export market, and entering the US market will face more trade barriers and access restrictions. Developed economies represented by the EU are accelerating the implementation of green barrier policies, the trend of politicization of environmental and climate issues is prominent, and the Carbon Border Adjustment Mechanism (CBAM) has brought new challenges to the foundry industry.

Outlook for the Foundry Industry During the “15th Five-Year Plan” Period

Looking ahead to the “15th Five-Year Plan” period, China’s foundry industry will embark on a new journey of high-quality development. With cultivating new productive forces as the core and ensuring the security and stability of the industrial chain and supply chain of the equipment manufacturing industry as the fundamental goal, it will address the shortcomings of industrial development, expand its strengths, and improve foundry basic manufacturing and collaborative innovation capabilities. Faced with challenges such as accelerated technological iteration, diversified market demand, and intensified international competition, the entire industry must anchor development goals with strategic perseverance, embrace changes with a more open attitude, strengthen industry-university-research-institute-application collaborative innovation, realize leapfrog development from scale expansion to quality improvement, and provide more solid support for the high-quality development of the equipment manufacturing industry.