Medical devices are a crucial cornerstone of human health initiatives, and their performance and quality directly impact the accuracy of medical diagnosis and the safety of treatment. In today’s era of rapid advancements in medical technology, precision machining has become a core link in ensuring the reliability of medical devices. We have deeply rooted ourselves in the field of precision machining for medical devices, and with a rigorous attitude, professional technology, and continuous innovation capabilities, we provide high-precision and high-stability machining solutions for the industry, empowering the development of medical technology.

Precision as the Foundation: Escorting Medical Safety

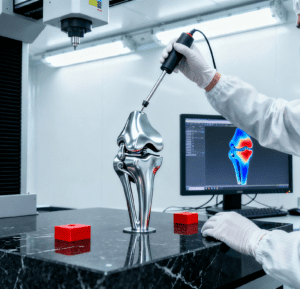

The precision requirements for medical devices far exceed those of ordinary industrial products. Micron-level dimensional errors or surface defects may affect the functionality of the devices and even pose threats to patient safety. We fully understand the uniqueness of this field and have always integrated “precision” into every link, from raw material selection to production process design. By leveraging advanced CNC machining equipment and precision measurement systems, combined with an experienced technical team, we ensure that products meet strict requirements in key dimensions such as complex structures, micro-apertures, and high surface finish. For products with extremely high precision requirements—such as orthopedic implants, minimally invasive surgical instruments, and core components of imaging equipment—we have established a comprehensive quality control system, and use scientific management processes to ensure the traceability of the machining process and the consistency of results.

In-depth Integration of Technology and Processes

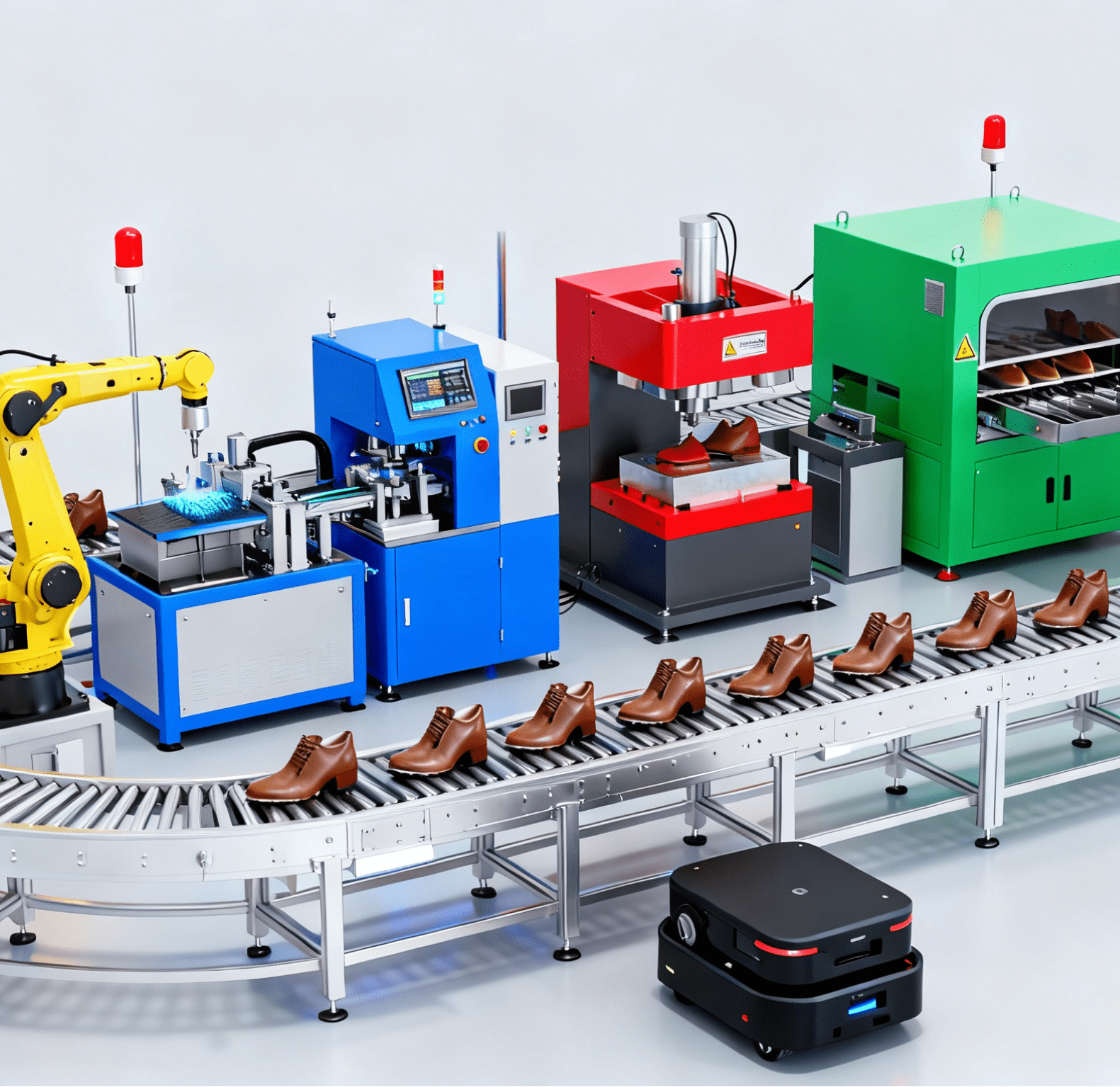

Machining medical devices not only requires equipment precision but also relies on an in-depth understanding of material properties, functional requirements, and clinical scenarios. We focus on research into the machining of diversified materials for medical use, such as medical-grade metals (e.g., titanium alloys, stainless steel), polymer materials, and special ceramics. We customize exclusive process solutions based on the physical properties of different materials. For instance, we have achieved technological breakthroughs through process innovation in areas such as low-stress machining of biocompatible materials, multi-axis linkage forming of complex curved surfaces, and stability control of ultra-thin-walled structures. We have also integrated flexible automatic loading and unloading vibrators into the production line—these devices feature adjustable vibration frequency and adaptive clamping structures, enabling gentle and precise automatic feeding and unloading of micro-components such as minimally invasive surgical forceps tips, implant screws, and medical sensor casings. They avoid surface scratches or structural damage caused by manual operation, while ensuring the positioning accuracy of workpieces within ±0.01mm, perfectly matching the high-precision machining needs of small medical parts. Meanwhile, we keep pace with industry development trends, actively exploring the integrated application of emerging technologies (such as additive manufacturing and micro-machining) with traditional processes, and providing technical support for the research and development of high-complexity medical devices.

Rigorous Quality System: Building a Trust Bond

The production of medical devices must comply with strict quality management systems, and we have always regarded compliance as the lifeline of the enterprise. From environmental cleanliness control to production process standardization, and from in-process inspection to finished product testing, every link is aligned with international standards for the medical device industry. We have established quality control nodes covering the entire process, and through a combination of automated testing equipment and manual re-inspection, we ensure that product performance is highly consistent with design specifications. At the same time, we continuously optimize our quality management system, actively participate in industry technical exchanges, and ensure that our service capabilities are updated in sync with regulatory requirements, providing solid support for our customers’ medical device registration and production licensing.

Customized Services: Empowering Product Innovation

The demand for diversification and personalization of medical devices is becoming increasingly prominent. From conventional devices to innovative equipment, precision machining services need to balance standardization and flexibility. We provide full-process services from drawing optimization and process design to mass production. In response to customers’ R&D needs, we form cross-disciplinary technical teams to conduct collaborative research and tackle key problems. Whether it is the rapid response in the prototype trial-manufacturing stage or the efficient delivery in the mass production stage, we are customer demand-oriented. Through scientific project management and supply chain collaboration, we help customers shorten the product launch cycle. We believe that only by deeply understanding the functional logic and usage scenarios of medical devices can we truly achieve the leap from “machining” to “value creation”.

Sustainable Development: Practicing Industry Responsibilities

While pursuing technological refinement, we have always focused on green manufacturing and the improvement of resource efficiency. By optimizing machining parameters, introducing environmentally friendly cooling processes, and promoting material recycling, we reduce energy consumption and waste emissions in the production process. We are committed to exploring a sustainable development path in the field of precision machining, providing solutions for the medical industry that combine technical value and environmental friendliness.

Joining Hands with You to Build a Healthy Future

Precision machining of medical devices is an undertaking that requires long-term accumulation and dedicated investment. We always treat every product with a sense of awe and use our professional capabilities to safeguard the warmth of medical technology. If you are looking for a trustworthy precision machining partner, please feel free to contact us. Let us take technology as a bridge to jointly promote the progress of the medical device industry and contribute solid strength to the cause of human health.