Multi-axis simultaneous intelligent machining technology for 5-axis CNC machine tools is a pivotal innovation in modern manufacturing. It enables simultaneous control over the movements of multiple axes to achieve highly efficient and precision machining of complex curved surfaces. This article will systematically analyze the core principles of this technology, including how multi-axis synchronization enhances machining accuracy and efficiency. Subsequently, it will explore its applications in the machining of aerospace components, facilitating the production of lighter yet more robust parts. Finally, it will focus on the mold manufacturing sector, demonstrating how to break through precision limits and optimize component quality. Through these discussions, readers can gain a comprehensive understanding of how this technology drives industrial progress.

Core Technology Analysis of Multi-Axis Simultaneous Machining

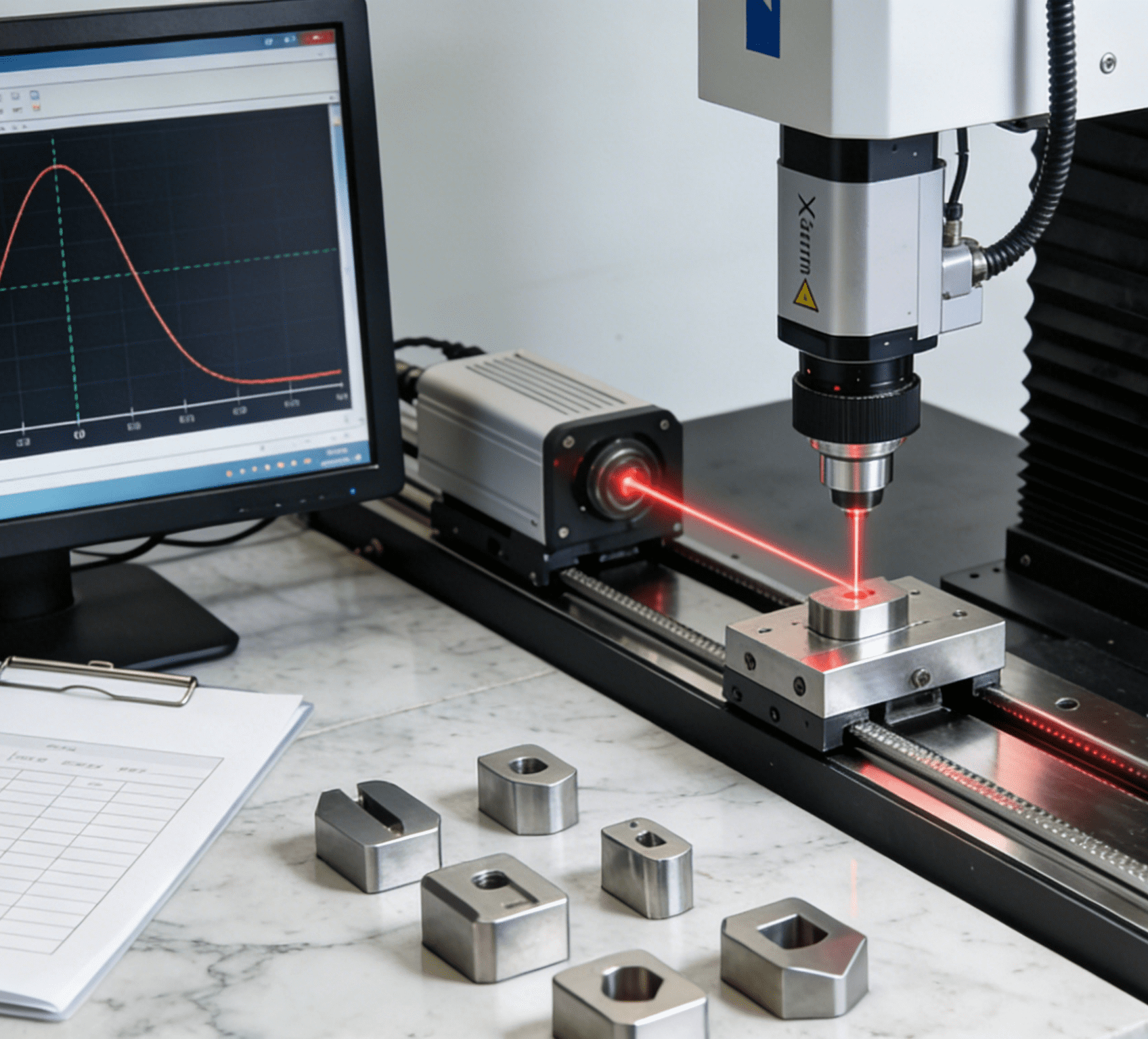

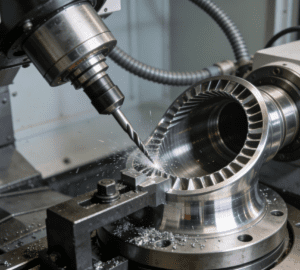

Multi-axis simultaneous machining technology is the core function of 5-axis CNC machine tools, playing a critical role in intelligent machining. It coordinates the simultaneous movements of multiple axes—such as the combination of rotary axes and linear axes—to achieve high-efficiency machining of complex curved surfaces. The core technologies include precise motion control algorithms and synchronization systems, which ensure real-time position adjustments of each axis and prevent errors. In practical applications, this technology reduces machining time and improves precision, laying a solid foundation for the efficient machining of aerospace components and molds in subsequent processes.

Implementation Path for High-Efficiency and Precision Machining

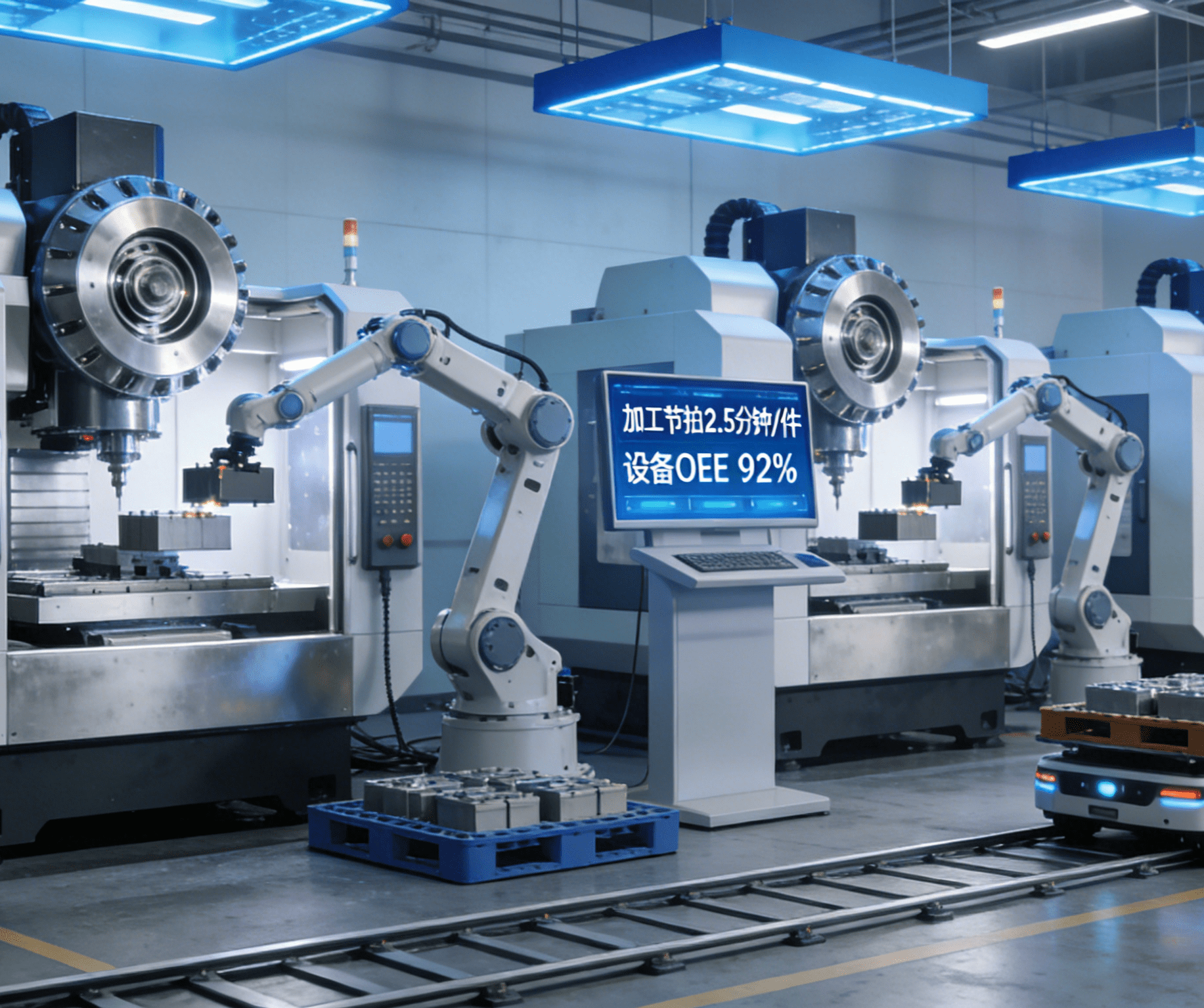

After mastering the core multi-axis simultaneous machining technology of 5-axis CNC machine tools, the key to achieving high-efficiency and precision machining lies in optimizing the machining path. By reducing the number of workpiece clamping operations, the machine can continuously machine complex curved surfaces from multiple angles, significantly shortening machining time. In addition, advanced motion control software can adjust tool paths in real time, ensuring that dimensional accuracy reaches the micron level. For example, in the manufacturing of aerospace components, such path optimization improves efficiency by over 20% while reducing material waste. This not only increases overall machining speed but also provides a reliable basis for precision enhancement in subsequent mold manufacturing.

Precision Enhancement in Aerospace Component Machining

The multi-axis simultaneous capability of 5-axis CNC machine tools has brought remarkable improvements, especially in the manufacturing of aerospace components. Many key components in the aerospace field—such as engine turbine blades and complex structural parts of aircraft fuselages—feature highly irregular shapes with numerous curved surfaces. In the past, machining these parts required multiple clamping and position adjustment procedures, which were time-consuming, labor-intensive, and prone to errors. Now, with the multi-axis simultaneous intelligent machining technology of 5-axis machine tools, cutting tools can flexibly move in multiple directions simultaneously, easily achieving precision cutting of complex curved surfaces. This means that complex parts that previously required multiple processes and clamping operations can now be machined efficiently and with high precision in a single clamping setup. Notably, the micron-level precision of these machined components also provides a reliable installation benchmark for Automatic spring equipment, which is widely used in assembling precision spring structures of aerospace engines; the high dimensional consistency ensures that the automatic spring equipment can complete the assembly of key spring components with high accuracy, further guaranteeing the overall performance and reliability of aerospace equipment. This not only drastically shortens production time but, more importantly, significantly improves the machining accuracy and overall quality of these key components, meeting the extremely high requirements for reliability and performance in the aerospace sector.

New Breakthroughs in Mold Manufacturing Precision

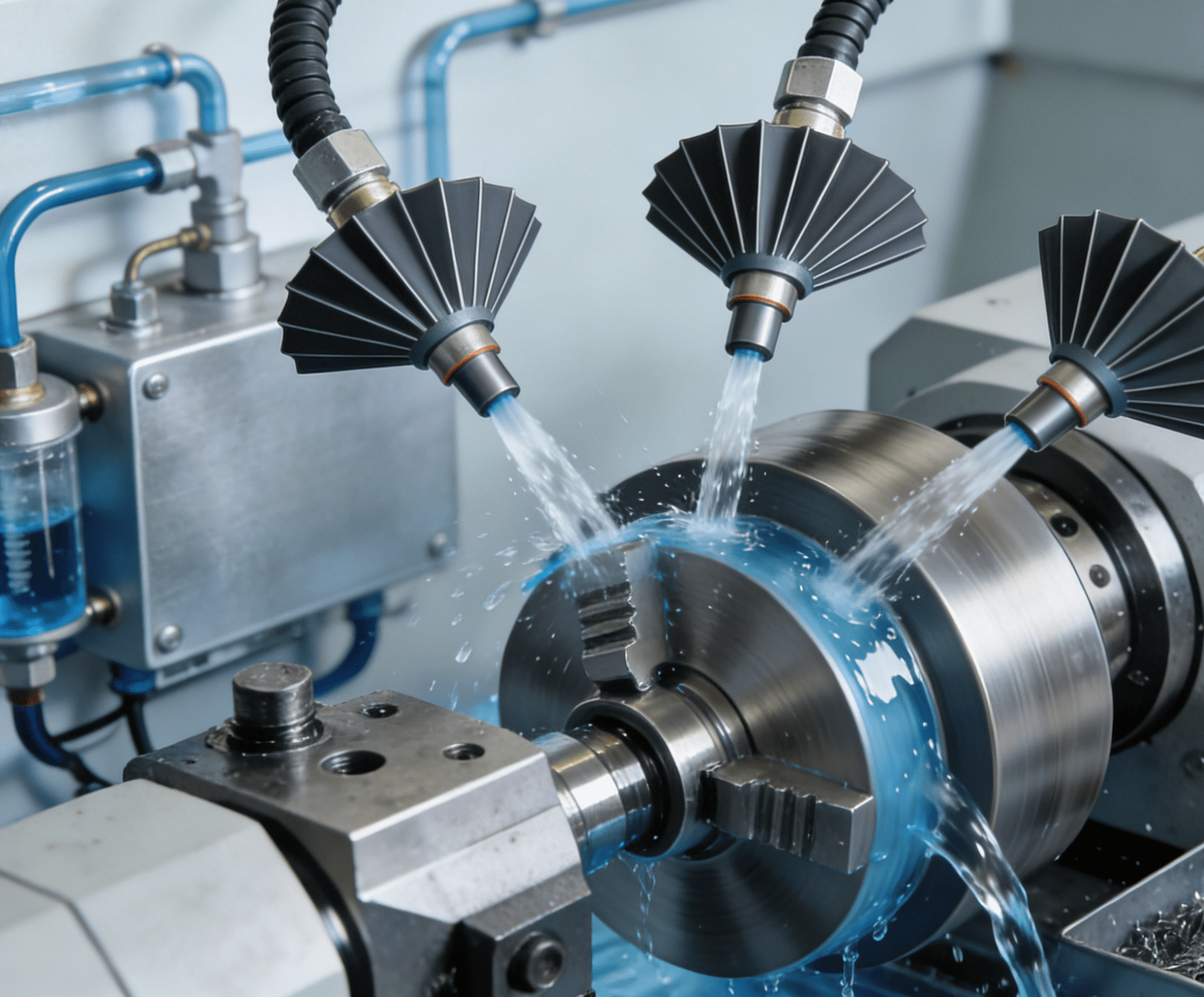

Similarly, in the mold manufacturing sector, the multi-axis simultaneous technology of 5-axis CNC machine tools has led to a significant leap in precision. By controlling the movements of multiple axes simultaneously, this system can easily handle complex curved surfaces and internal details, such as the intricate structures of automotive molds or mobile phone casings. This reduces errors in traditional machining processes and ensures high dimensional consistency of components. Meanwhile, the high processing speed shortens production cycles, helping enterprises deliver high-quality products more quickly. In addition, multi-axis simultaneous machining can adapt to a wide range of materials, opening up new possibilities for the mold industry.

By controlling the movements of multiple axes simultaneously, the multi-axis simultaneous technology of 5-axis CNC machine tools makes the machining of complex curved surface parts faster and more precise. This not only shortens overall machining time but also improves component quality and reduces material waste: in aerospace manufacturing, it supports the production of lighter and stronger parts; in mold manufacturing, it delivers higher precision and faster production speeds. Ultimately, this intelligent machining technology is driving progress across multiple industries, enabling smarter and more efficient manufacturing processes.