Medical syringes are essential devices in clinical treatment, medical testing and vaccine injection, with extremely strict requirements on production precision, sterility and consistency. Traditional manual or semi-automatic assembly methods can no longer meet the high standards of modern medical device manufacturing. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, focuses on the R&D and production of medical syringe automatic assembly equipment, integrating high precision, customization and efficiency to help global medical manufacturers achieve intelligent and standardized production.

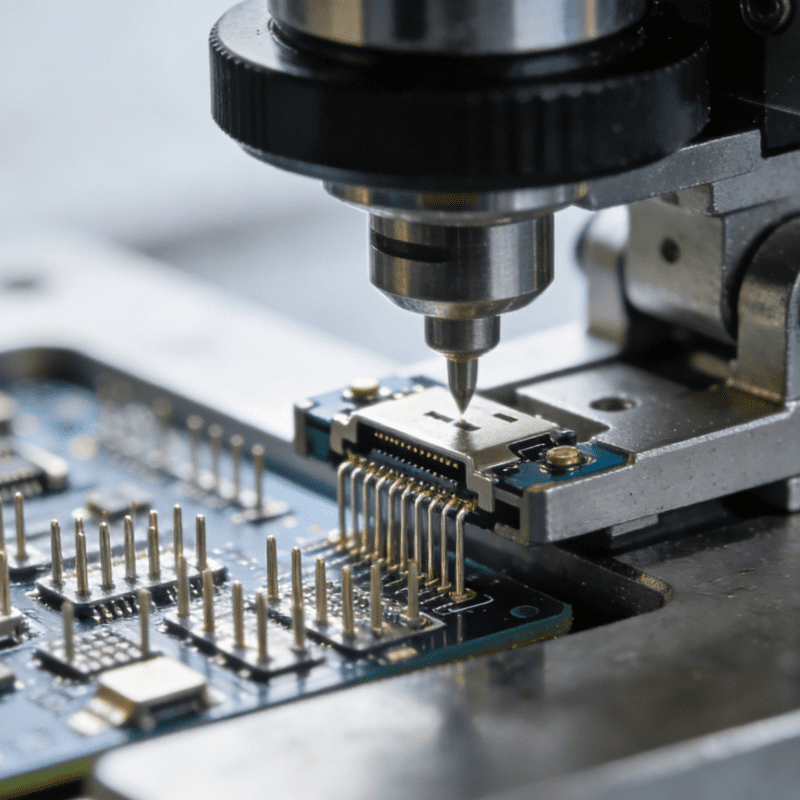

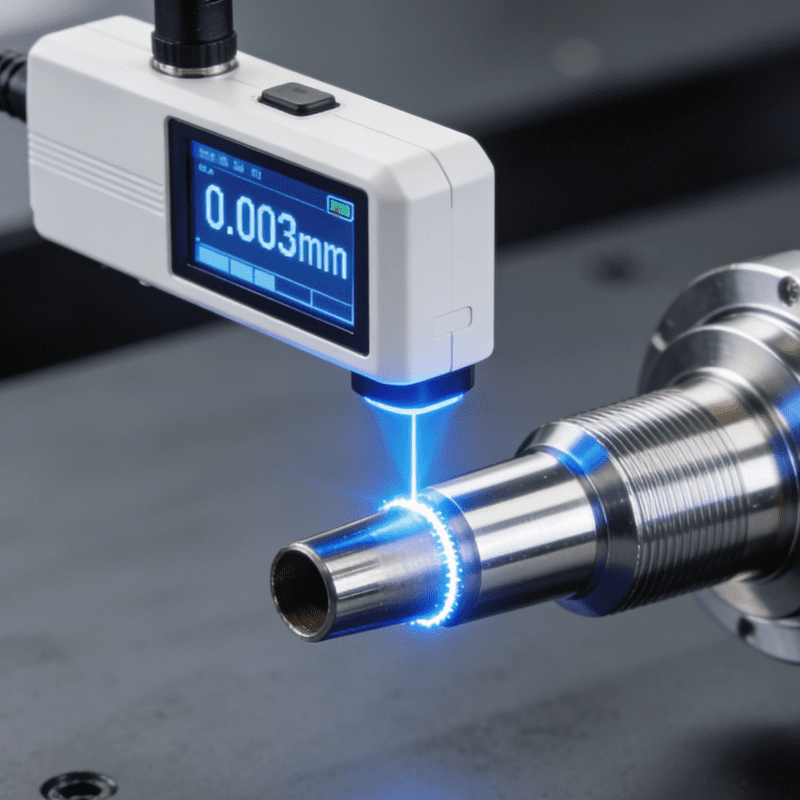

Medical-Grade Precision: Guarding Product Safety

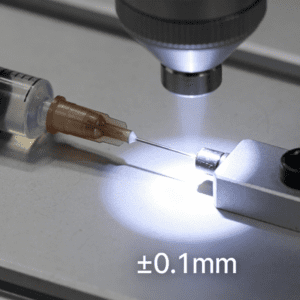

The safety of medical syringes is directly related to patient health, so assembly precision is the core requirement of equipment. Ruizhi’s medical syringe automatic assembly equipment adopts advanced servo control system and high-precision positioning technology, with an assembly error controlled within ±0.1mm, fully complying with ISO 7886-2:2020 international medical standards and GMP production specifications. Equipped with intelligent visual inspection and leak testing modules, it can automatically detect unqualified products such as needle deviation, poor piston sealing and shell cracks, ensuring that every finished syringe meets medical-grade standards and eliminating potential safety hazards caused by human error.

Adapting to Diverse Medical Needs

Medical syringes have diverse specifications and models, including insulin syringes, vaccine syringes, disposable syringes of different sizes, and special-shaped syringes for clinical specialties. Standard assembly equipment cannot adapt to these diverse needs. Ruizhi Intelligent Manufacturing has rich experience in non-standard customization, and can provide personalized equipment solutions according to customers’ product parameters, assembly processes and production capacity. We optimize module configuration, adjust assembly procedures and design special fixtures to perfectly match customers’ production lines, realizing flexible production of multi-model syringes and reducing production costs.

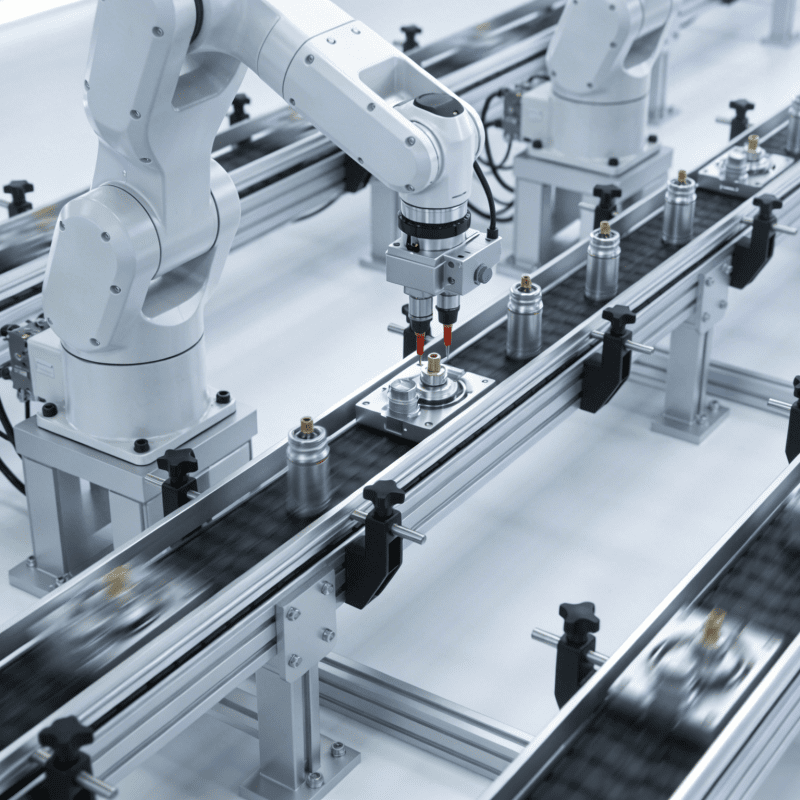

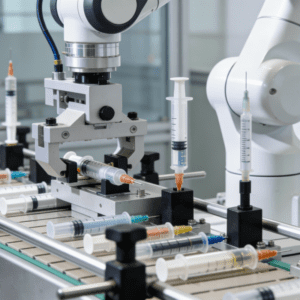

Empowering Intelligent Production

In medical device production, efficiency and stability are crucial to reducing costs and increasing efficiency. Ruizhi’s medical syringe automatic assembly equipment realizes fully automated operation from component feeding, precise assembly, online inspection to finished product sorting, replacing 6-10 manual positions, with an hourly output of up to 24,000 syringes. The equipment adopts modular design, which reduces failure rate and maintenance difficulty, and the average continuous operation time can reach more than 800 hours. In addition, we provide one-stop after-sales service including installation, commissioning and technical training to ensure long-term stable operation of equipment and help customers achieve efficient and intelligent production upgrades.

Ruizhi Intelligent Manufacturing is committed to using non-standard automation technology to empower the medical device industry. Our medical syringe automatic assembly equipment integrates precision, customization and efficiency, providing reliable production support for global medical manufacturers and contributing to the development of the medical health industry.